Self-adaptive flexible discharging plasma device

A discharge plasma, self-adaptive technology, applied in the direction of plasma, electrical components, etc., can solve the problems of low efficiency, high discharge requirements, uneven treatment effect, etc., achieve low energy consumption, low discharge voltage requirements, and improve composite processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

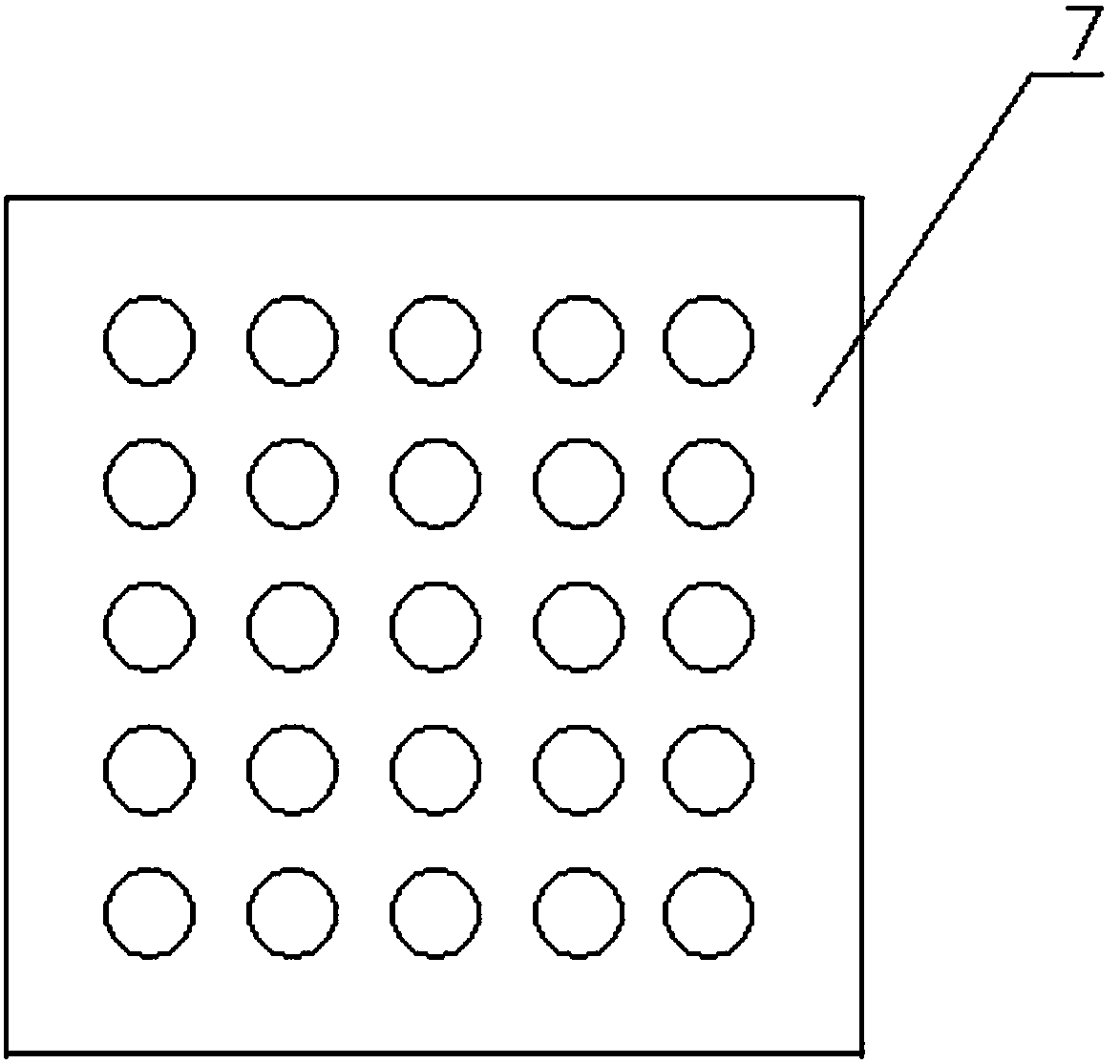

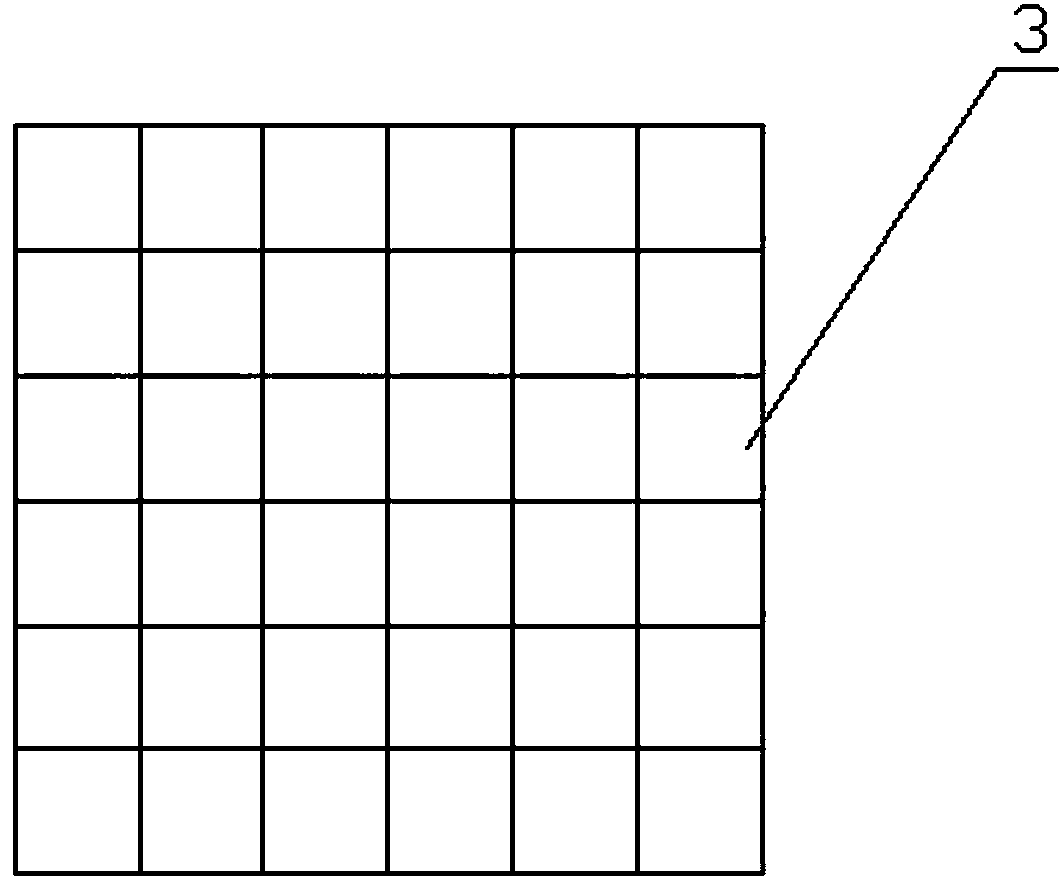

[0024] exist figure 1 figure 2 and image 3 In the schematic diagram of the present invention shown, a medium body A2 is provided on the upper part of the base 1, the lower surface of the medium body A is viscous, and the lower surface of the medium body A is closely attached to the upper part of the base. A high-voltage electrode 3 is arranged on the upper part of the dielectric body A, and the high-voltage electrodes are arranged in a well shape, and the high-voltage electrodes are connected to the high-voltage power supply through wires. A dielectric body B4 is provided on the upper surface of the high-voltage electrode, and the lower surface of the dielectric body B is viscous, and the lower surface of the dielectric body B is closely attached to the upper part of the dielectric body A. The upper surface of medium body B is provided with photocatalyst material 5, is provided with medium body C6 on the top of photocatalyst material, the lower surface of medium body C has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com