Automatic tension control apparatus for longitudinally covered wire

An automatic control device and wire tension technology, applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of increasing the rate of waste of defective products, and achieve the effect of avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

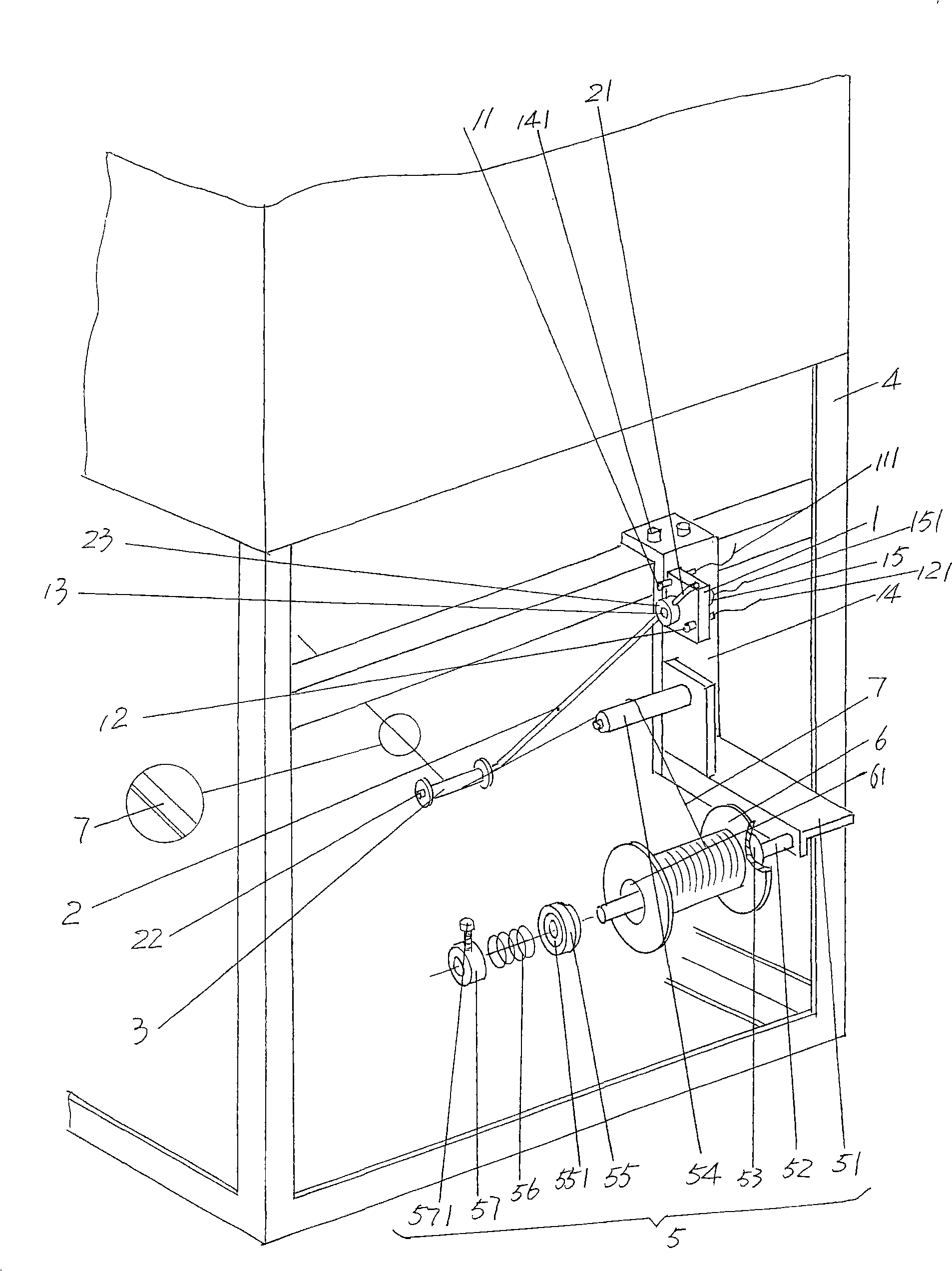

[0012] See figure 1 , provides a knitting machine 4, the outer side of the knitting machine 4 is equipped with a longitudinally covered wire supply device 5, the structure of the longitudinally covered wire supply device 5 is the same as that in the prior art, including a base 51 , longitudinally covered wire reel 52, first and second bearing blocks 55, 53, transition rod 54, spring 56, spring adjustment sleeve 57, base 51 is fixed on the outer sidewall of braiding machine 4, longitudinally covered wire reel 52 It is fixed on the base 51 in a cantilever state, the first bearing seat 55 is arranged on the longitudinally wrapped wire disk shaft 52 through the bearing 551, the second bearing seat 53 is also arranged on the longitudinally covered wire disk shaft 52 through the bearing, and the transition rod 54 is set on the base 51 and is located above the longitudinally-enclosed wire reel shaft 52 and is parallel to the longitudinally-enclosed wire reel shaft 52. The spring 56 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com