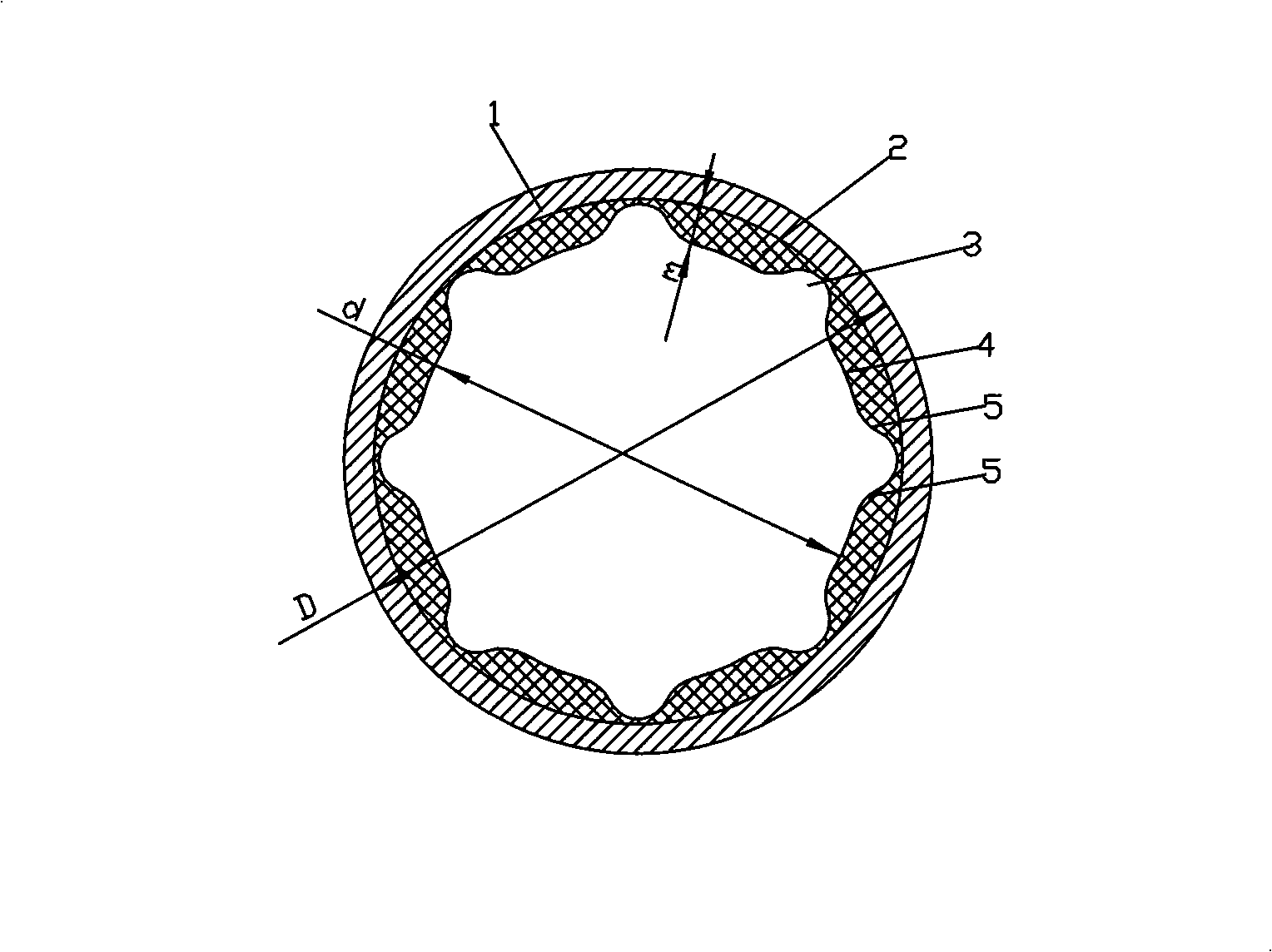

Water lubrication rubber alloy bearing

A rubber alloy, water-lubricated technology, used in shafts and bearings, bearing components, mechanical equipment, etc., can solve the problem of not being able to achieve the best matching of bearing capacity and seismic capacity, without comprehensive consideration of bearing capacity and seismic capacity, and discharging sediment. It can save valuable non-ferrous metals and lubricating materials, save the lubricant supply system, and enhance the ability to discharge sediment and impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

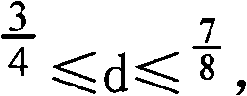

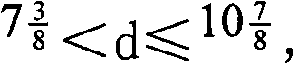

[0066] The material of the water-lubricated rubber alloy bushing of the present embodiment comprises the following components by weight: 40Kg of nitrile rubber, 3Kg of zinc oxide, 1Kg of sulfur, 1Kg of N-cyclohexyl-2-benzothiazole sulfenamide, dibutyl Nickel dithiocarbamate 1Kg, C16 saturated fatty acid 1Kg, semi-reinforcing carbon black 60Kg, molybdenum disulfide 20Kg.

Embodiment 2

[0068] The material of the water-lubricated rubber alloy bushing of the present embodiment comprises the following components by weight: 70Kg of nitrile rubber, 5Kg of zinc oxide, 2Kg of sulfur, 2Kg of N-cyclohexyl-2-benzothiazole sulfenamide, dibutyl Nickel dithiocarbamate 2Kg, C16 saturated fatty acid 2Kg, semi-reinforcing carbon black 70Kg, molybdenum disulfide 40Kg.

Embodiment 3

[0070] The material of the water-lubricated rubber alloy bushing of the present embodiment comprises the following components by weight: 100Kg of nitrile rubber, 8Kg of zinc oxide, 3Kg of sulfur, 3Kg of N-cyclohexyl-2-benzothiazole sulfenamide, dibutyl Nickel dithiocarbamate 3Kg, C16 saturated fatty acid 3Kg, semi-reinforcing carbon black 80Kg, molybdenum disulfide 60Kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com