Strippable water-soluble silk screen ink for temporary protection

A technology of screen printing ink and temporary protection, applied in the direction of ink, printing, application, etc., can solve the problems that the mold cannot be closely combined with the transparent plastic panel, affect the aesthetics of the panel, and the edge of the window is not neat, and achieves easy implementation and excellent solvent resistance. , easy peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Take 60g of R-970 water-based polyurethane resin and place it in a container, and add materials while stirring at a speed of 700RPM. Add 1g of BYK-020 water-based defoamer, 1g of DISPERBYK-191 water-based dispersant, BYK-346 water-based Wetting agent 1g, humectant propylene glycol 12g, water-based active clay filler 22g, RM-8W type thickener 3g, and then stirred and mixed for 20 minutes, promptly made the strippable water-based screen printing ink for temporary protection of the present invention.

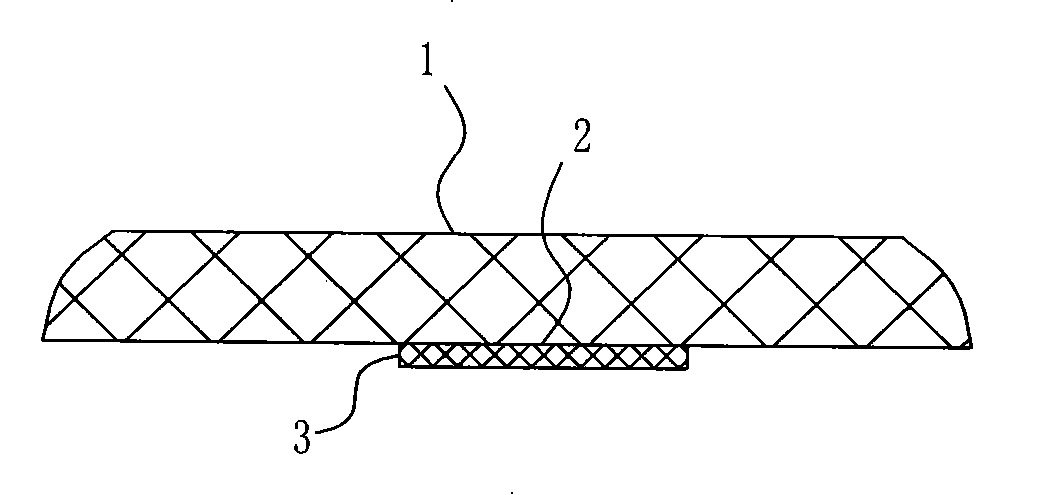

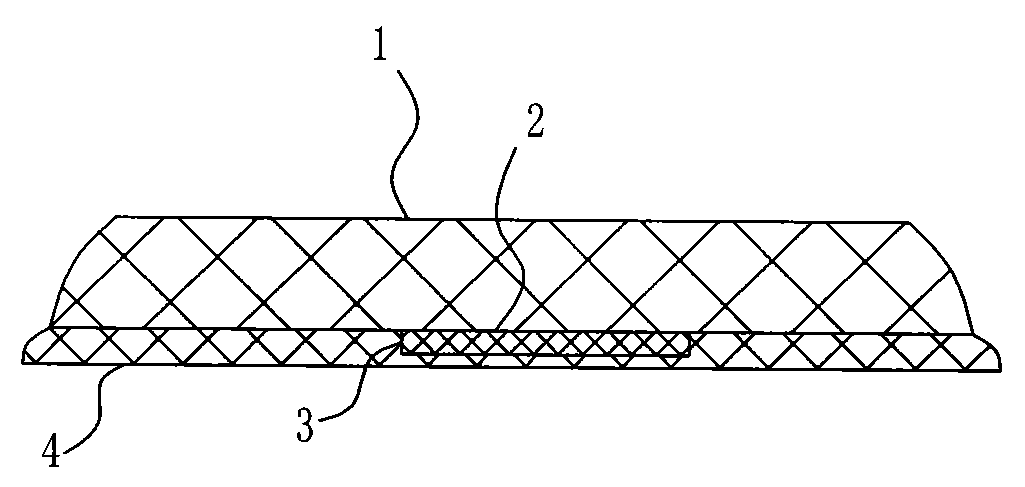

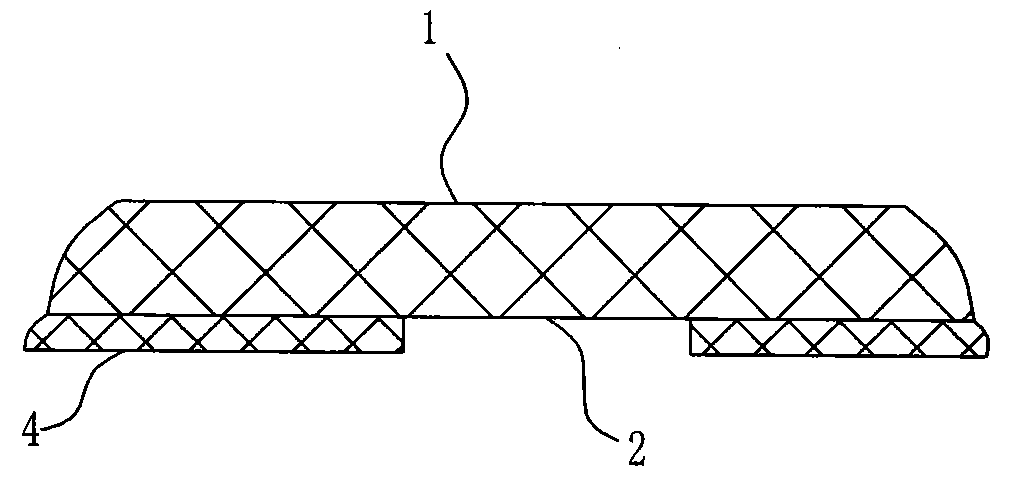

[0033] The process of the application of the strippable water-based screen printing ink for temporary protection of the present invention in the panel processing of electrical appliances and electronic products is as follows: Figure 1 ~ Figure 3 shown. Such as figure 1 , first screen-print the peelable water-based screen printing ink 3 for temporary protection on the window 2 on the back of the plastic panel 1, after drying, and then figure 2 Spray solvent-based paint 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com