Burnishing surface wood oriented structure chipboard and manufacture method and use thereof

A chipboard and flat surface technology, applied in the field of improved wood oriented strand board and its manufacturing, can solve problems such as unevenness, secondary processing production cost increase, OSB surface roughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

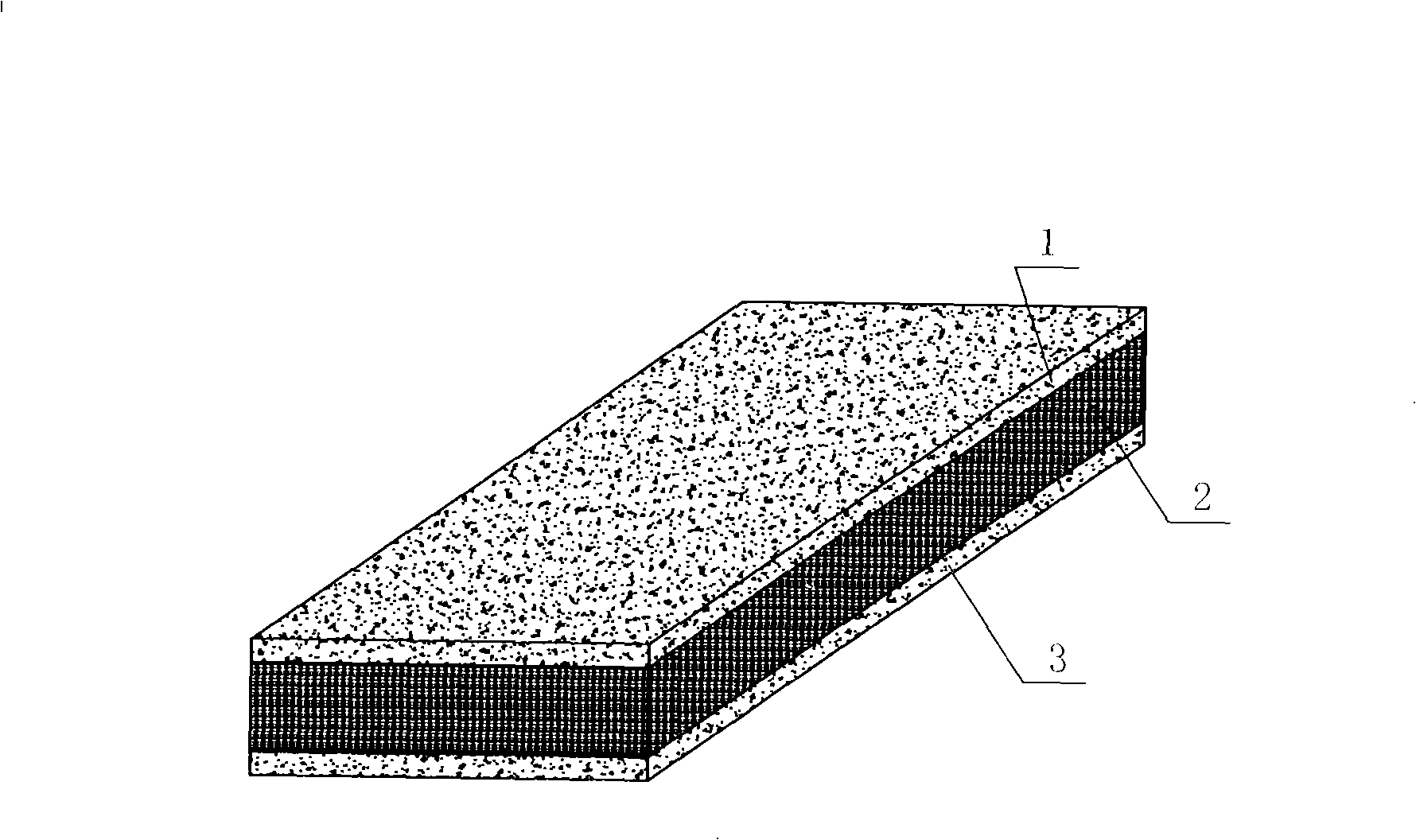

[0024] The core layer 2 of the flat surface wood oriented strand board is OSB, which will be processed along the direction of the wood grain with a length of 30mm-150mm, a width of 5mm-30mm, and a thickness of 0.3mm-1.2mm. After five layers are installed, it is then heat-pressed and formed. The surface layer 1 and the bottom layer 3, that is, the first layer and the last layer, are made of wood after slicing, softening, grinding and fiber separation, after drying, screening, and phenolic resin as the adhesive for sizing and paving, and the core layer 2 combined, then pre-pressed and hot-pressed, and finally finished with plain surface treatment to form a three-layer structure, the core layer 2 is OSB, the surface layer 1 and the bottom layer 3 are wood fine material layers with a smooth surface wood oriented strand board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com