A cleaning head for a porous plate

A cleaning head and porous plate technology, applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem of water injection pressure, poor uniformity of water injection volume, no consideration of fluid pressure performance, and is not suitable for small Scale experiments and other issues to achieve the effect of improving efficiency, easy cleaning and maintenance, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

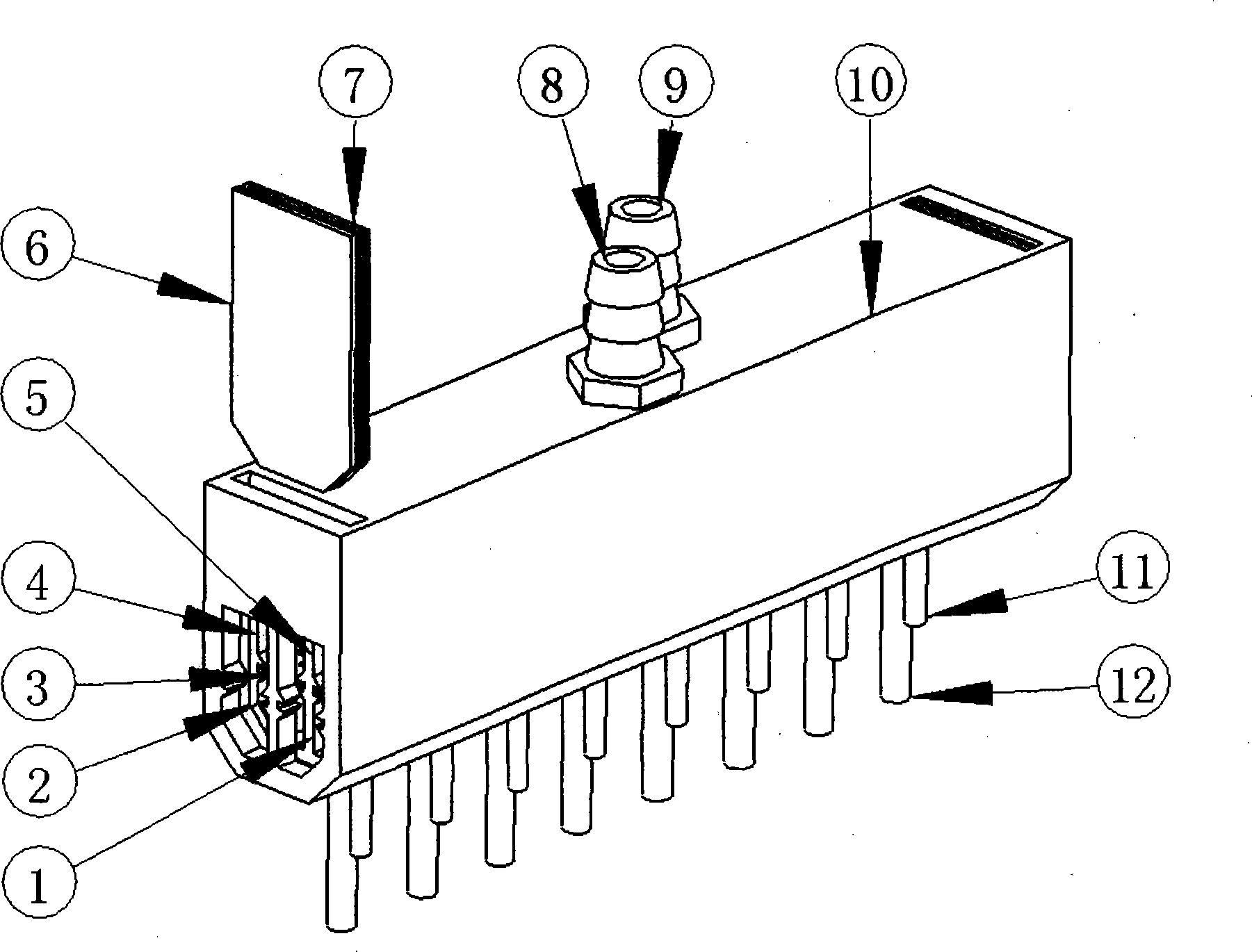

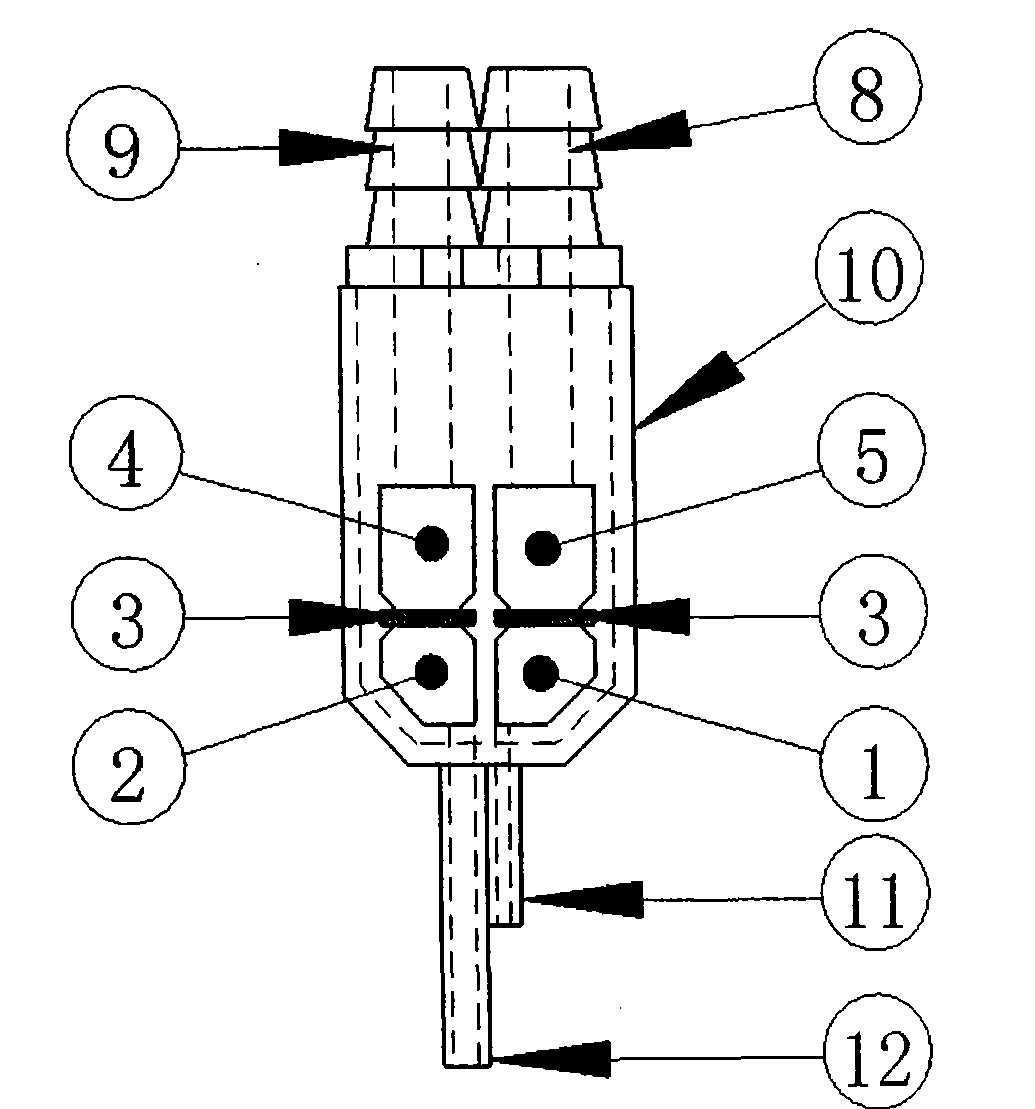

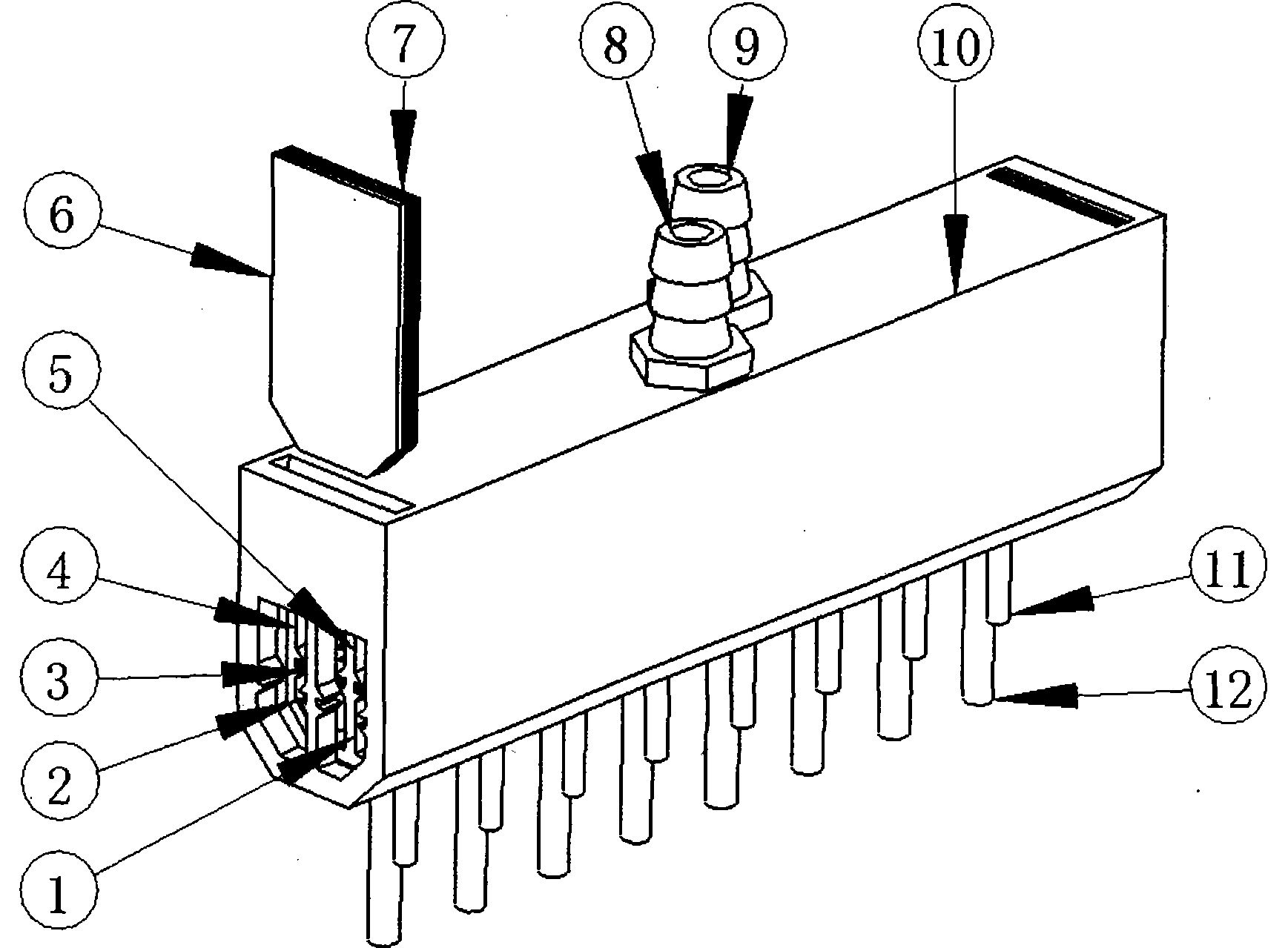

[0022] Below in conjunction with accompanying drawing, and the specific embodiment when the quantity of water suction pipe (12) and water injection pipe (11) is 8, the present invention is further described:

[0023] As shown in Figures 1 and 2, a cleaning head according to the present invention includes a row of water suction pipes (12), a row of water injection pipes (11), a water injection interface (8), a water outlet interface (9), The main body (10), two side plates (6), two side plate rubber pads (7), two porous partitions (3), and the main body (10), side plate rubber pads (7) and porous The partition plate (3) contains and separates four chambers formed by the water injection chamber (1), the water outlet chamber (2), the water injection buffer chamber (5), and the water outlet buffer chamber (4).

[0024] The water suction pipe (12) and the water injection pipe (11) are arranged in two rows at a certain distance, and the distance between the water suction pipe (12) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com