Beverage preparation machine having a liquid level sensor

A liquid level sensor and beverage preparation technology, applied in the field of beverage preparation machines, can solve problems such as easy failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

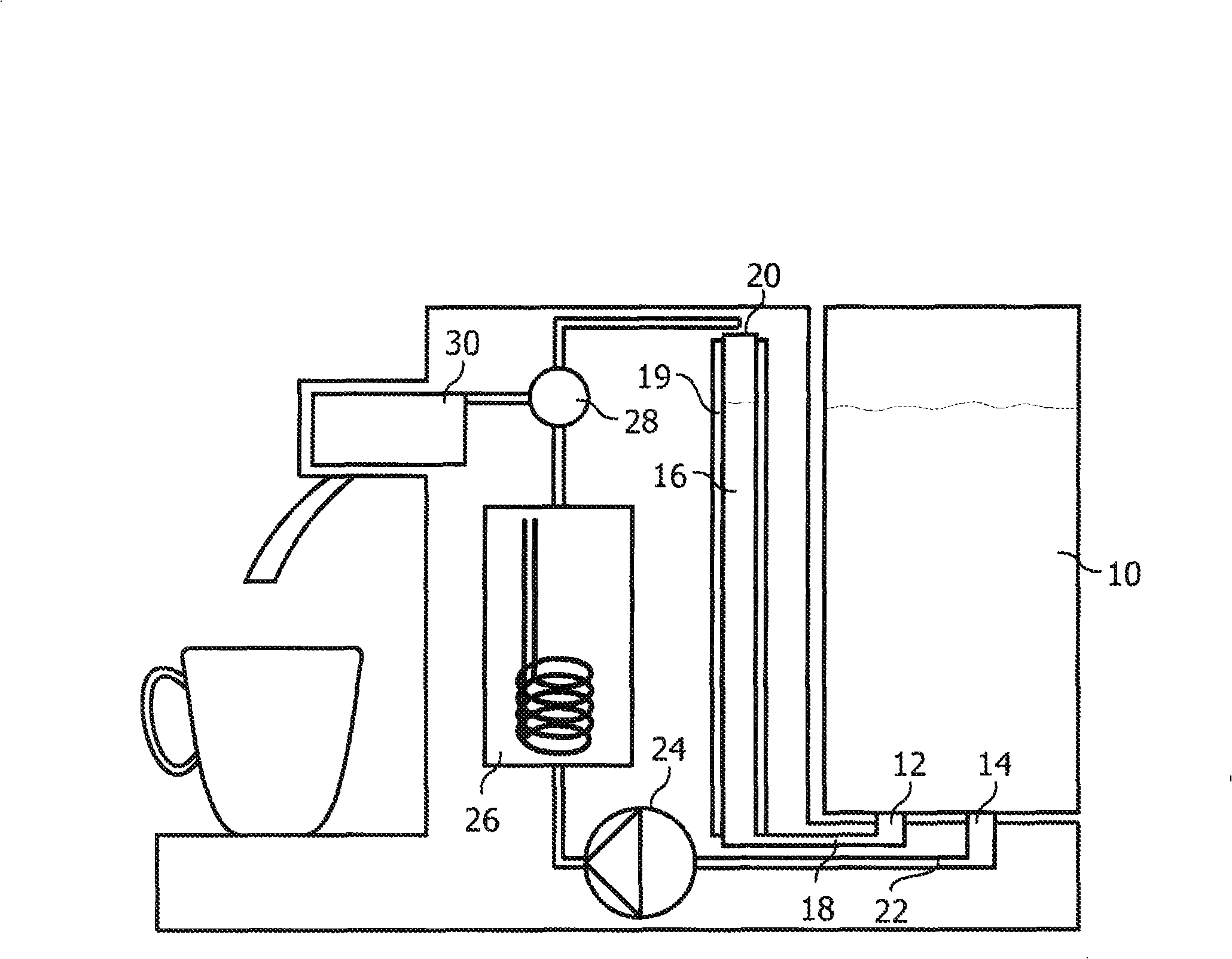

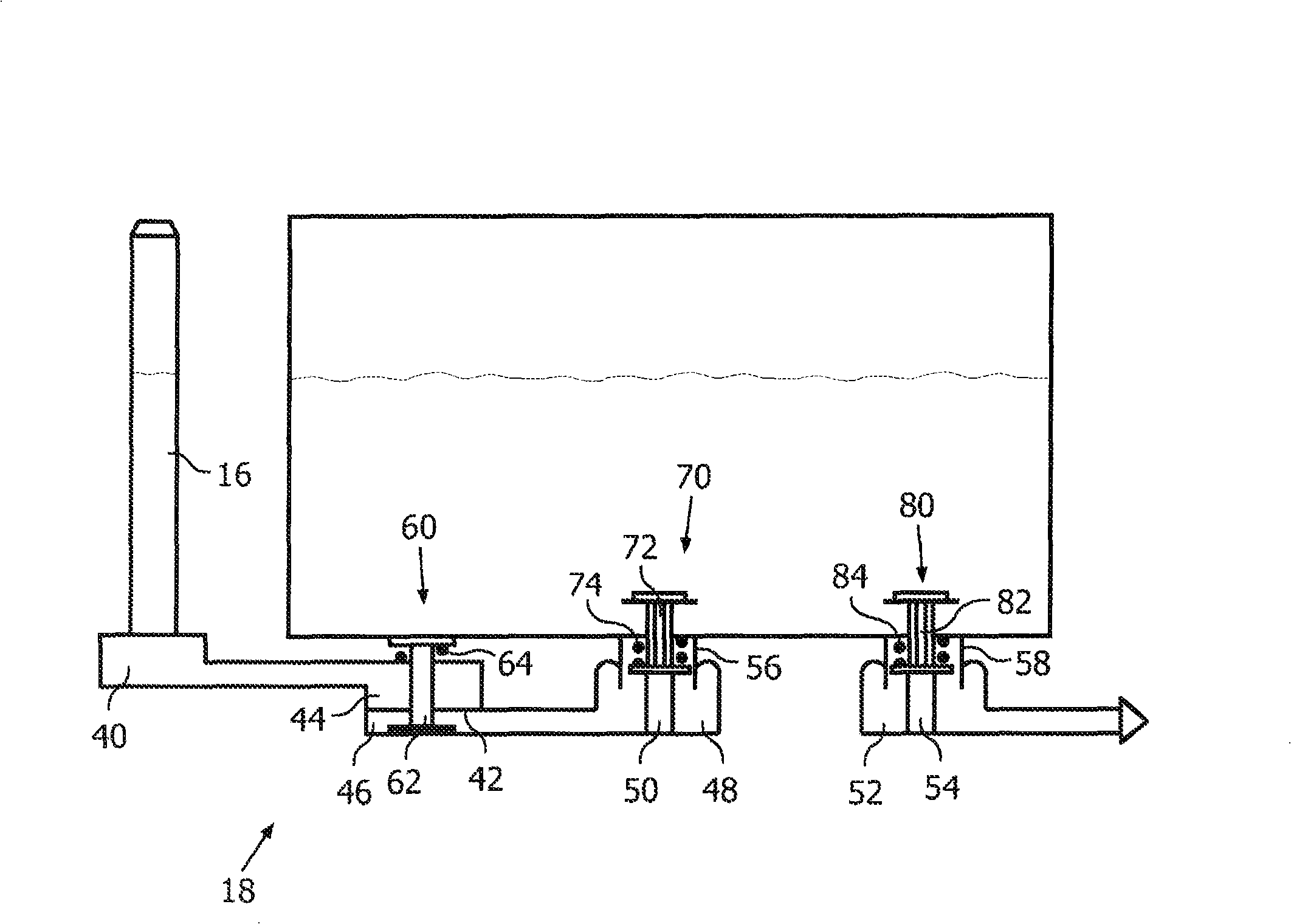

[0016] figure 1 A beverage preparation machine according to the invention is shown. The beverage preparation machine comprises a separable liquid container 10 for storing a liquid, usually water or water including some additives. The beverage preparation machine is adapted to receive and hold the liquid container 10 so that the connection described later can be made with the beverage preparation machine in the state where the liquid container is installed in its intended position. Through the bottom of the liquid container 10, two outlets 12 and 14 are formed. If the separable liquid container 10 is installed in a beverage preparation machine, the outlet 12 communicates with the riser tube 16 through the connection part 18 . The riser 16 is an elongated cylindrical pipe whose longitudinal axis extends in the direction of gravity beyond the upper maximum fill level of the installed liquid container 10 (in this detailed description, terms such as "upper" or "lower" are pointi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com