Electric control device for modularization high-power electromagnetic range and control method

A modular control and electronic control device technology, applied in the direction of emergency protection circuit devices, induction heating control, electrical components, etc., can solve the problems of not forming a product series that meets the power demand, unstable heating firepower, poor control accuracy, etc., to achieve Power expansion and upgrading are convenient, enhance safety and stability, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

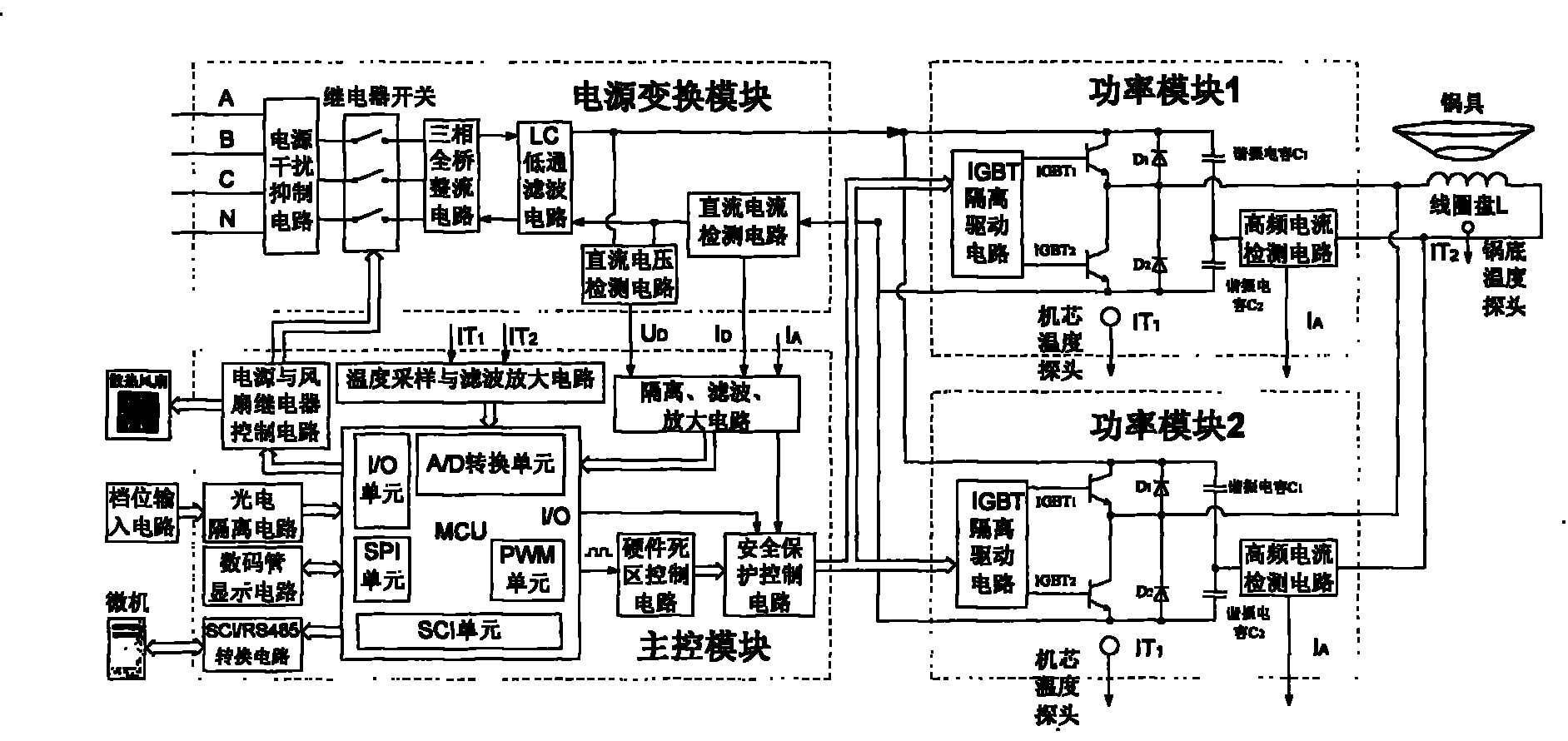

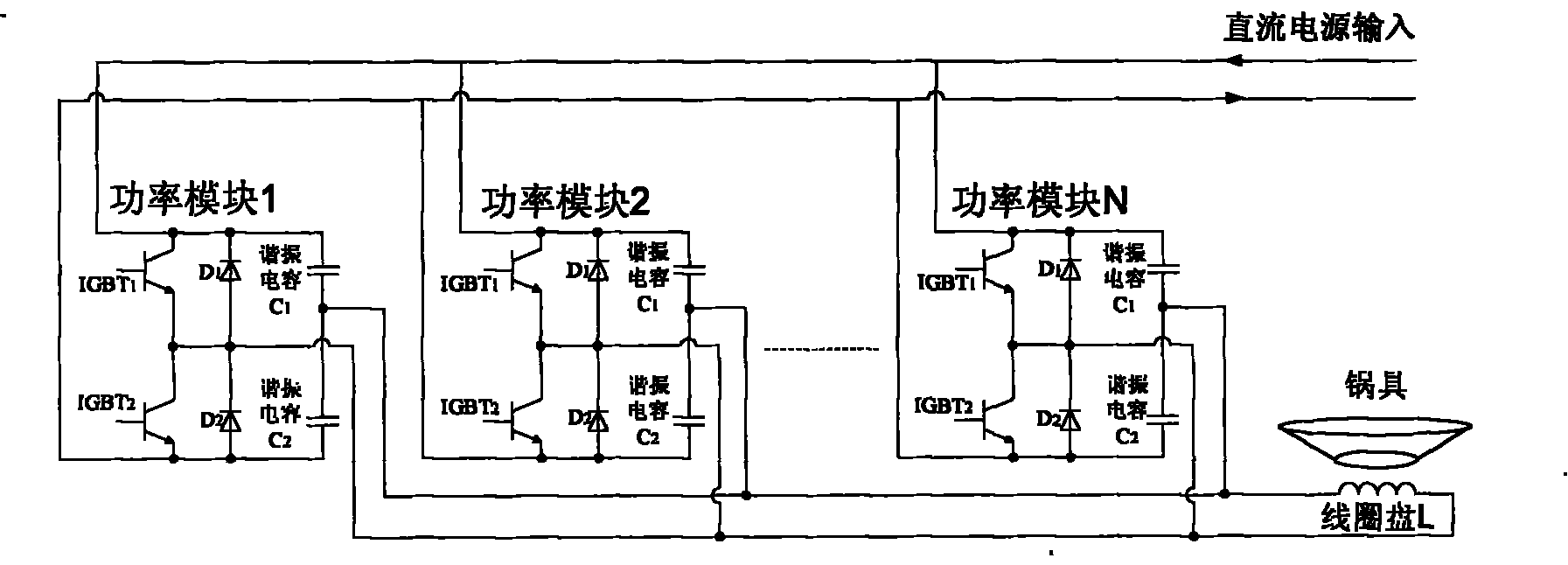

[0037] Such as figure 1 The shown embodiment 1 of the present invention is a dual-power module electromagnetic cooker electric control device, which adopts a modular control structure. The main part consists of a power conversion module, two independent power modules with consistent parameters, and a main control module. Component composition.

[0038] Power conversion modules such as figure 1 As shown, it consists of a power supply interference suppression circuit, a relay switch, a three-phase full-bridge rectifier circuit, an LC low-pass filter circuit, a DC voltage detection circuit, and a DC current detection circuit. The power supply interference suppression circuit is a three-phase neutral line filter composed of a three-phase common-mode inductor and a power suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com