Column support insulator and porcelain bushing ultrasonic wave electrified flaw detection special-purpose probe

A pillar insulator and ultrasonic technology, applied in the direction of material analysis, measuring devices, instruments, etc. using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as influence, complexity, and difficulty, and achieve the effect of ensuring safety, reasonable design, and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

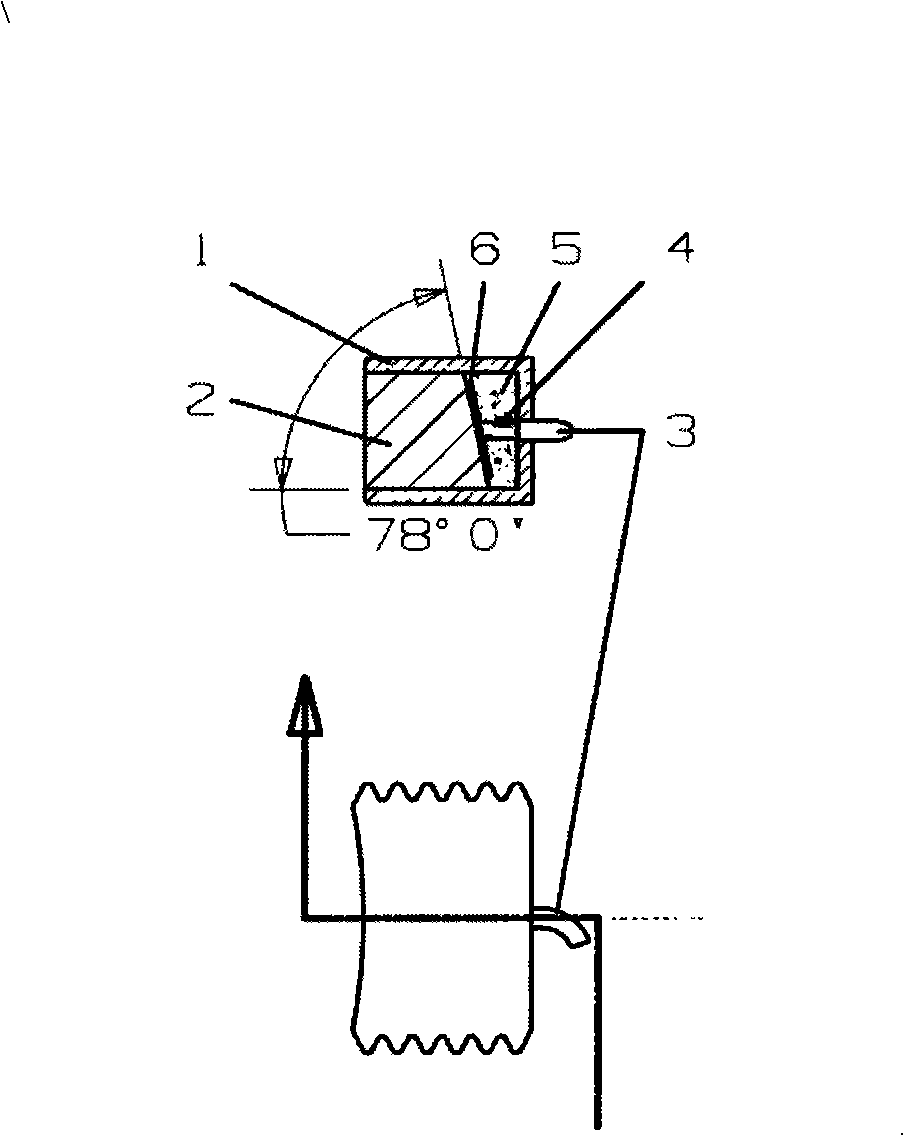

[0011] like figure 1 As shown, this embodiment includes: an insulating shell 1 , a plexiglass contact block 2 , a wire 3 , a coil wire 4 , a filling material 5 , and a piezoelectric crystal 6 . The insulating shell 1 is a rectangular insulating shell with one end closed. The insulating shell 1 has corrugations on both sides of the concave surface of the plexiglass block in the axial direction. The corrugations can increase the creepage distance. The upper and lower sides are smooth surfaces. One end of the insulating shell 1 Closed, the wire 3 is led out from the clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com