TGRM subsection moving-on type advanced deep hole grouting construction process

It is a construction technology and advanced technology, which is applied to mining equipment, earthwork drilling, tunnels, etc. It can solve problems such as waste of materials, backflow of grout, and inability to guarantee the effect of grouting, so as to avoid damage and ensure construction safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

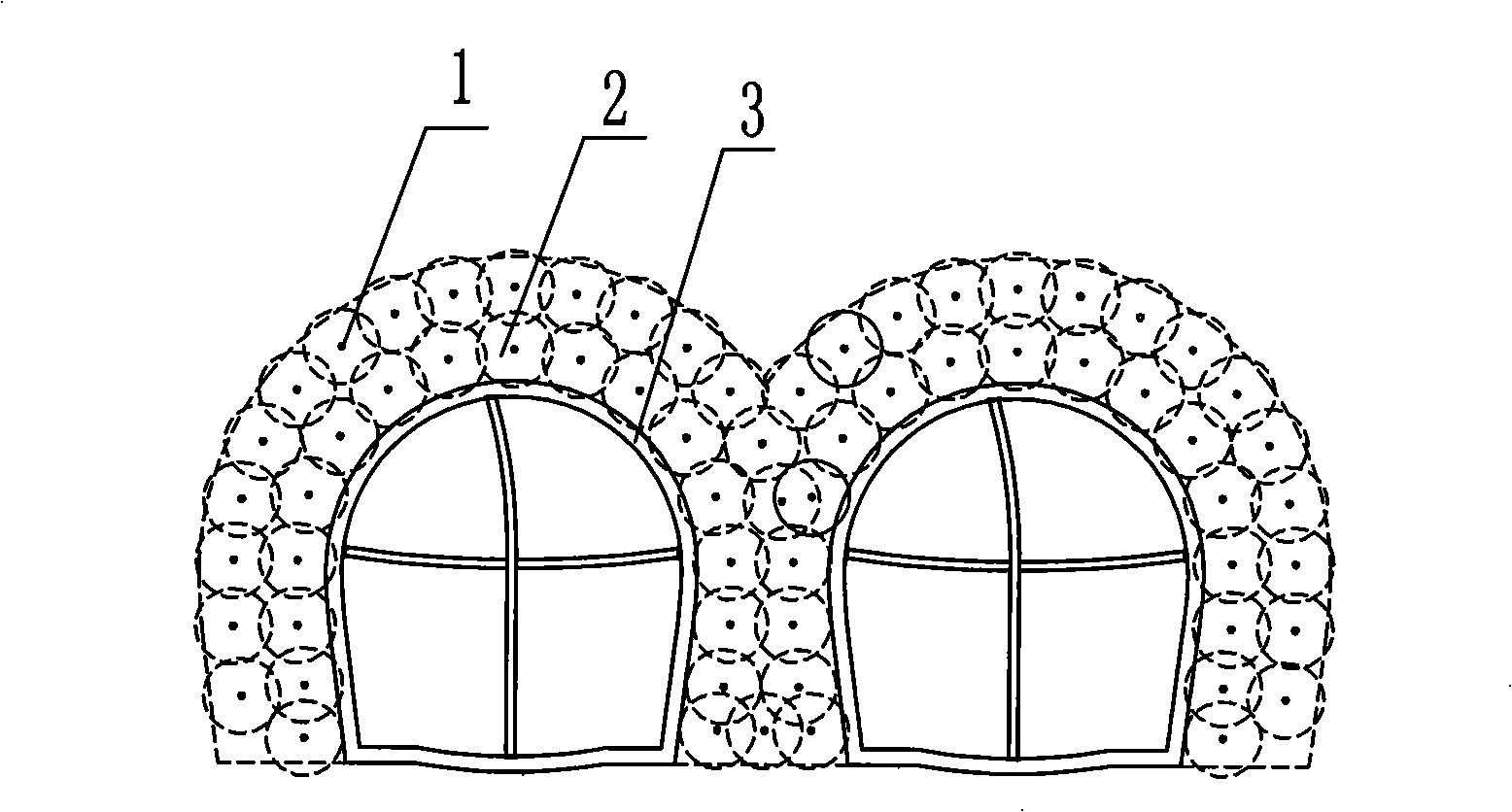

Image

Examples

Embodiment

[0030] Example: The mileage K14+0.0 of the double-cavity tunnel between Xizhimen and the zoo on Beijing Metro Line 4 is located directly under the Gaoliang Bridge with a total length of 105 meters. The arch of the stratum where the tunnel structure is located is sand and pebbles, and the arch waist is a sand stratum. In order to ensure the safety of the sorghum bridge during the excavation of the interval tunnel, the "TGRM step-by-step advanced deep hole grouting construction technology" of the present invention is adopted. .

[0031] The TGRM step-by-step advanced deep hole grouting construction technology described in this embodiment is used for underground excavation tunnel construction, and it includes the following steps:

[0032] ① Stop excavation when the tunnel is excavated to the extent where reinforcement is required, close the tunnel face, and construct a slurry wall;

[0033] ②Set the drilling angle, length, position and quantity according to the scope of pre-rein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com