Internal circulation hot gas heating device for vegetable fiber felt

A heating device and fiber mat technology, applied in heating/cooling fabrics, fabric surface trimming, textile and papermaking, etc., can solve the problems of low work efficiency, troublesome operation, unsafety, etc., to achieve convenient opening and closing, and improve work efficiency , the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

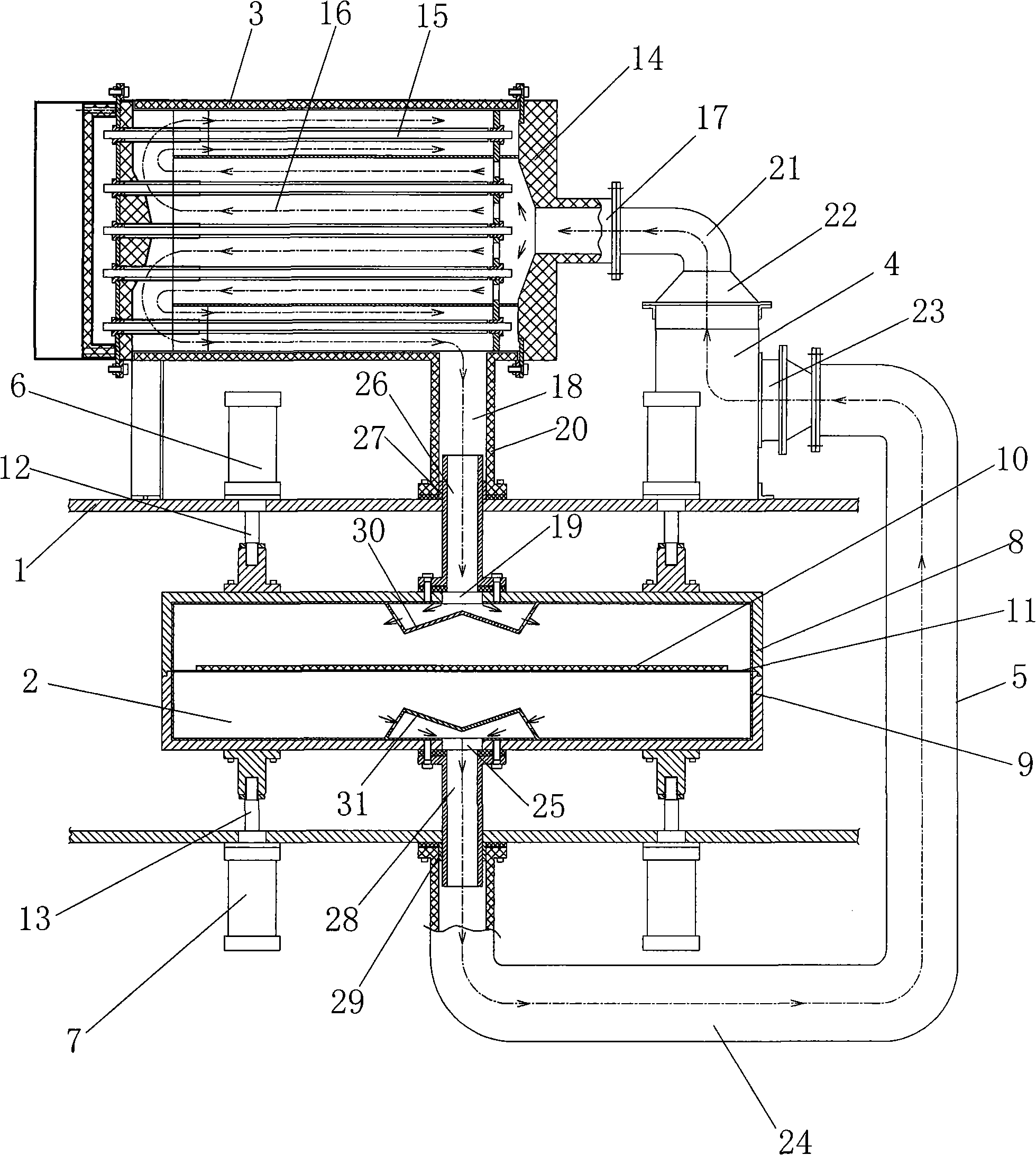

[0015] refer to figure 1 , the internal circulation hot air heating device of the vegetable fiber felt is characterized in that it includes a frame 1 and a heating chamber 2 installed on the frame 1, a heater 3, a fan 4, an air pipe 5, etc., and several cylinders 6, 7 etc., wherein the heating chamber 2 is composed of an upper part 8 of the heating chamber and a lower part 9 of the heating chamber which are closed or separated in the longitudinal direction, and the inside of the upper opening of the lower part of the heating chamber 9 is provided with a supporting net 11 for placing the vegetable fiber mat 10, several cylinders 6, 7 etc. are installed on the frame 1 respectively, and the piston rods 12, 13 of several cylinders 6, 7 etc. are respectively connected with the upper part 8 of the heating chamber and the lower part 9 of the heating chamber, and the heater 3 is composed of a shell 14 and a heating tube arranged in its cavity. 15, etc., circulating air passage 16, etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com