Preparation of cellulose solution

A cellulose solution and cellulose technology, applied in the field of cellulose solution preparation, can solve the problems of complicated cellulose dissolution process, high cost, harsh conditions, etc., and achieve the effects of shortening the dissolution time, promoting dissolution, and reducing preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

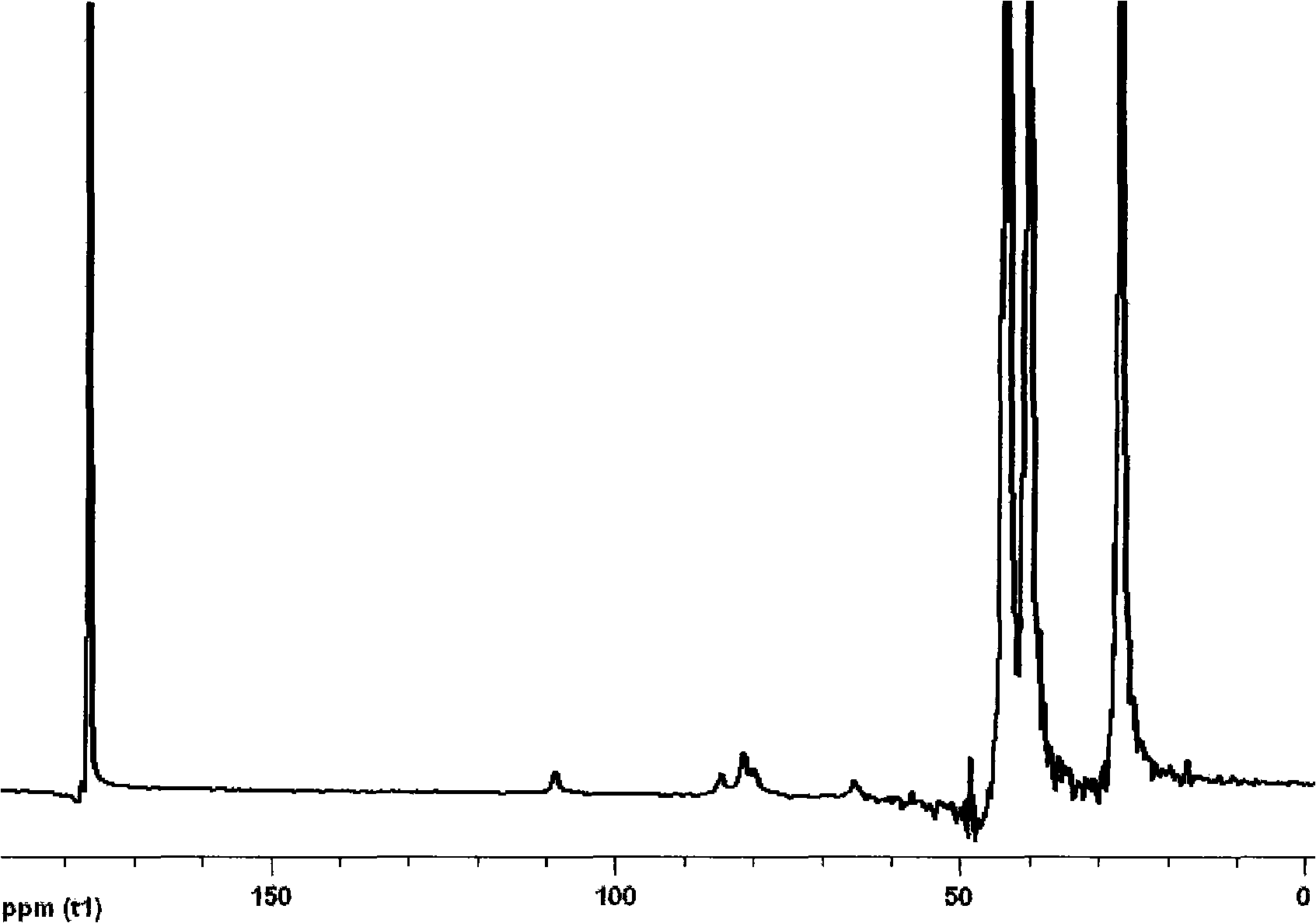

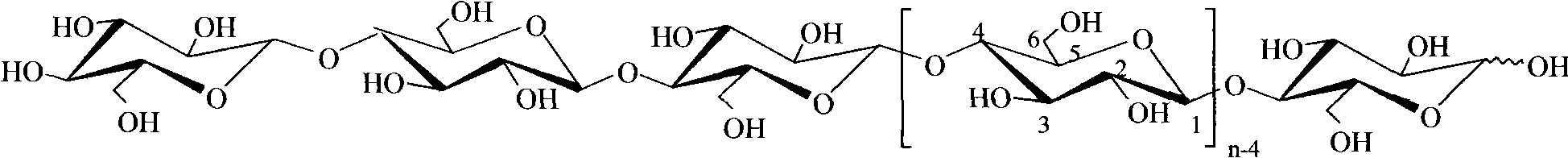

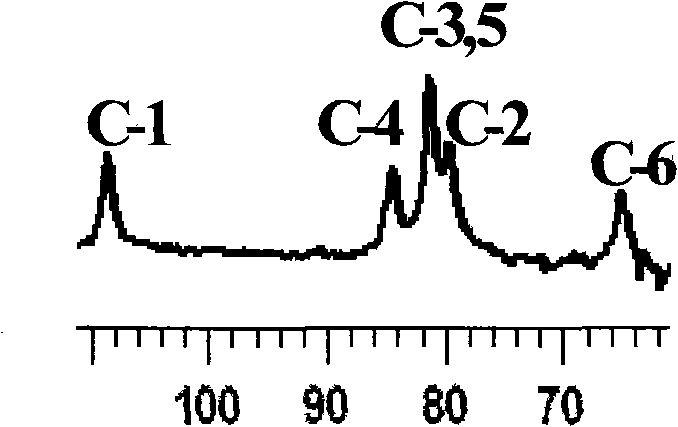

Image

Examples

Embodiment 1

[0025] Get microcrystalline cellulose 5g (viscosity average molecular weight 2.4 * 10 4 ), lithium chloride 8g and dimethylacetamide 100ml, and then ultrasonic treatment for 10 minutes, the frequency used is 20KHz, the power is 600w, after stirring evenly at room temperature, freeze at -6 °C for 3 hours to obtain A stable cellulose solution.

Embodiment 2

[0027] Get microcrystalline cellulose 8g (viscosity average molecular weight 3.1 * 10 4 ), lithium chloride 8g and dimethylacetamide 100ml, and then ultrasonic treatment for 15 minutes, the frequency used is 25KHz, and the power is 650w. After stirring at room temperature, freeze at -8°C for 3 hours to obtain A stable cellulose solution.

Embodiment 3

[0029] Get microcrystalline cellulose 15g (viscosity average molecular weight 3.1 * 10 4 ), lithium chloride 9g and dimethylacetamide 100ml, and then ultrasonic treatment for 20 minutes, the frequency used is 20KHz, and the power is 700w. After stirring at room temperature, freeze at -10°C for 4 hours to obtain A stable cellulose solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com