Preparation of mesoporous zircite

A technology of mesoporous zirconia and zirconium salts, applied in zirconia and other directions, to achieve the effect of novel ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

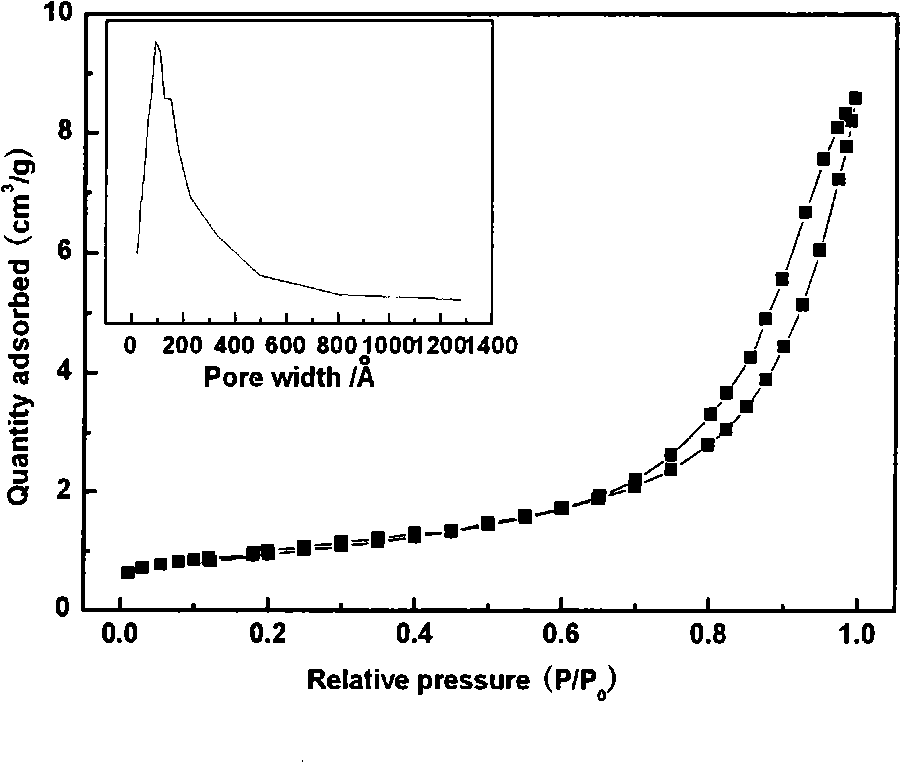

Embodiment 1

[0031] Use the following ratio (molar ratio) to configure the raw materials, zirconium oxychloride octahydrate: G1: NaOH: H 2 O=1:0.1:2:150. Dissolve G1 and NaOH in 140ml of water in a water bath at 80°C, stir at 300r / min for 1h, add the Zr salt solution dropwise at a rate of 1ml / min, continue stirring for 3h and age for 24h, then dissolve the suspension Transfer to a stainless steel reaction kettle, treat it in an oven at 110°C for 48h, and then take it out. The precipitate was washed alternately with water and hot ethanol at 80°C for several times, the filter cake was dried in an oven at 100°C, and the product was heated to 540°C at a rate of 3°C / min in a tube furnace and kept for 3.5 hours to obtain mesoporous ZrO 2 The nitrogen adsorption-desorption curve and corresponding pore size distribution curve of powder and product are shown in the attached figure 1 , the specific surface area of the product is 113m 2 / g.

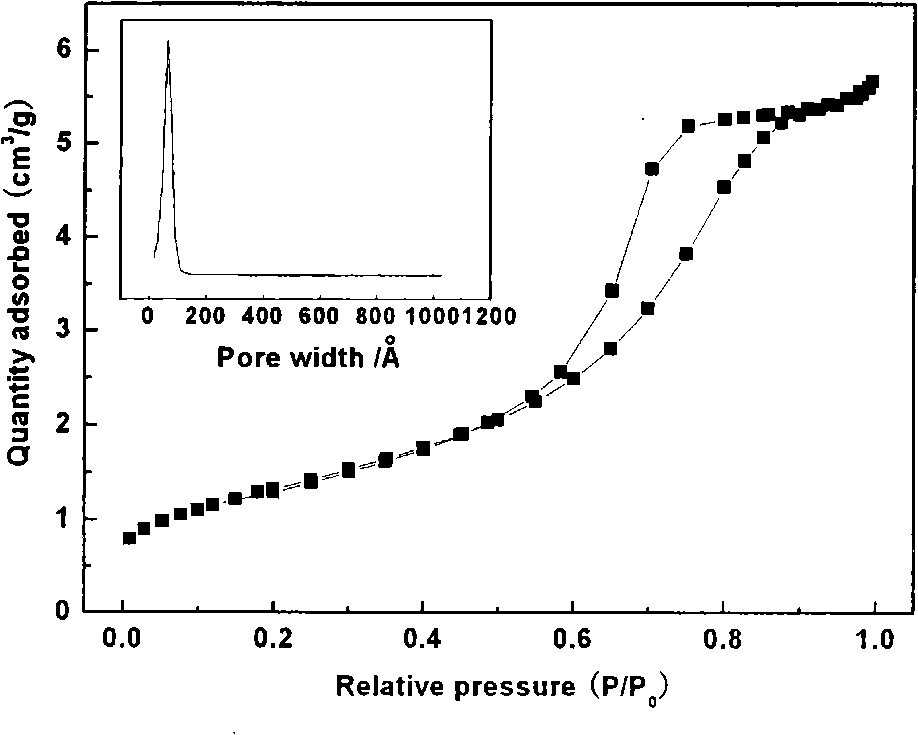

Embodiment 2

[0033] Use the following ratio (molar ratio) to configure the raw materials, zirconyl sulfate: CTAB: G2: NaOH: H2 O=1:0.055:0.055:2.5:150. Dissolve CTAB, G2 and NaOH in 140ml of water in a water bath at 80°C, stir at 300r / min for 1h, drop Zr salt solution at a rate of 2ml / min, continue stirring for 3h and age for 24h. The turbid liquid was transferred to a stainless steel reaction kettle, treated in an oven at 110° C. for 48 hours, and then taken out. After the precipitate was washed alternately with water and hot ethanol at 80 °C for several times, the filter cake was freeze-dried to directly obtain mesoporous ZrO 2 The nitrogen adsorption-desorption curve and corresponding pore size distribution curve of powder and product are shown in the attached figure 2 , the specific surface area of the product is 151m 2 / g.

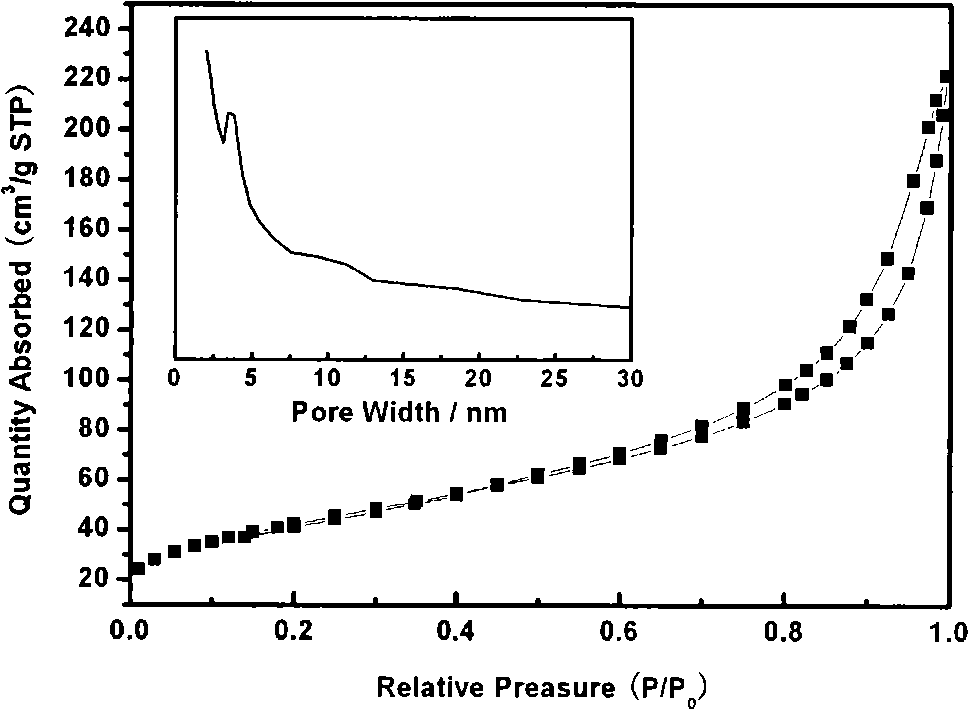

Embodiment 3

[0035] Use the following ratios (molar ratios) to configure the raw materials: zirconium oxychloride octahydrate: CTAB: G3: NaOH: H 2 O=1:0.7:0.5:2:150. Dissolve CTAB, G3 and NaOH in 140ml of water in a water bath at 80°C, stir for 1h under the condition of 300r / min, drop Zr salt solution at a speed of 1ml / min, continue stirring for 3h and age for 24h. The turbid liquid was transferred to a stainless steel reaction kettle, treated in an oven at 110° C. for 36 hours, and then taken out. After the sediment was washed alternately with water and hot ethanol at 80°C for several times, the filter cake was dried in an oven at 100°C, and the product was heated to 540°C at a rate of 3°C / min in a tube furnace and kept for 3 hours to obtain mesoporous ZrO 2 The nitrogen adsorption-desorption curve and corresponding pore size distribution curve of powder and product are shown in the attached image 3 , the specific surface area of the product is 160m 2 / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com