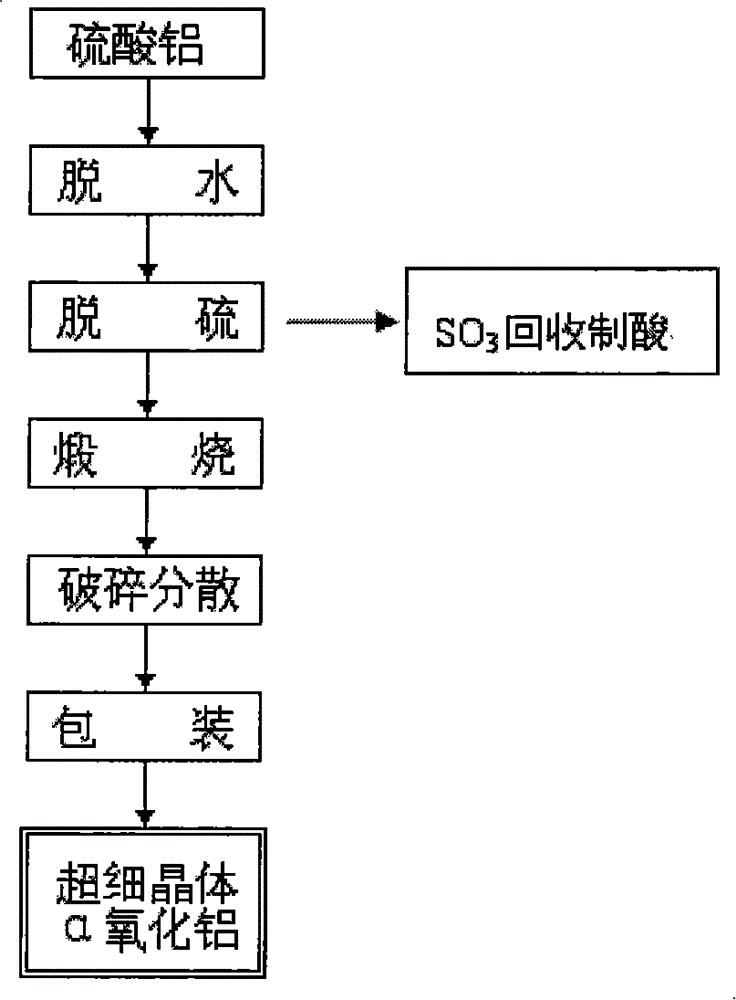

Production process for preparing superfine crystal alpha-aluminum oxide by directly using aluminum sulfate

A production process, the technology of aluminum sulfate, applied in the field of alumina production process, can solve the problems of inability to realize tiny crystallization, difficult control of technical conditions, strict production process requirements, etc., and achieve abundant raw material reserves, low production cost and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The production process for producing ultra-fine crystal α-alumina directly from aluminum sulfate provided in this example includes the following steps:

[0026] (1) After pulverizing the aluminum sulfate, heat to remove the crystal water of the alumina intermediate, and the heating temperature is 300° C.;

[0027] (2) The product obtained in step (1) is sealed to remove sulfur in the desulfurization tunnel by means of electric heating, and the heating temperature is 800°C;

[0028] (3) The product obtained in step (2) is subjected to phase inversion calcining with natural gas in a high-temperature furnace, and the calcining temperature is 1300° C.;

[0029] (4) breaking and dispersing the product obtained in step (3);

[0030] (5) Recover the sulfur trioxide gas produced by desulfurization to make acid.

Embodiment 2

[0032] The production process for producing ultra-fine crystal α-alumina directly from aluminum sulfate provided in this example includes the following steps:

[0033] (1) After pulverizing aluminum sulfate, heat to remove attached water and crystal water, and the heating temperature is 400°C;

[0034] (2) The product obtained in step (1) is sealed to remove sulfur in the desulfurization tunnel by means of electric heating, and the heating temperature is 900°C;

[0035] (3) heating the product obtained in step (2) in a high-temperature furnace for phase-inversion calcination, and the calcination temperature is 1100° C.;

[0036] (4) breaking and dispersing the product obtained in step (3);

[0037] (5) Recover the sulfur trioxide gas produced by desulfurization to make acid.

Embodiment 3

[0039] The production process for producing ultra-fine crystal α-alumina directly from aluminum sulfate provided in this example includes the following steps:

[0040] (1) After aluminum sulfate is crushed, the attached water and crystal water are removed by heating, and the heating temperature is 600°C;

[0041] (2) The product obtained in step (1) is sealed to remove sulfur in the desulfurization tunnel by means of electric heating, and the heating temperature is 700°C;

[0042] (3) heating the product obtained in step (2) in a high-temperature furnace for phase-inversion calcination, and the calcination temperature is 1400° C.;

[0043] (4) breaking and dispersing the product obtained in step (3);

[0044] (5) Recover the sulfur trioxide gas produced by desulfurization to make acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com