Method for calculating and installing high-speed rail electrification catenary wrist-arm

A technology for high-speed railways and installation methods, which is applied in computing, electrical digital data processing, and special data processing applications, and can solve problems such as complex positioning and large line time occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

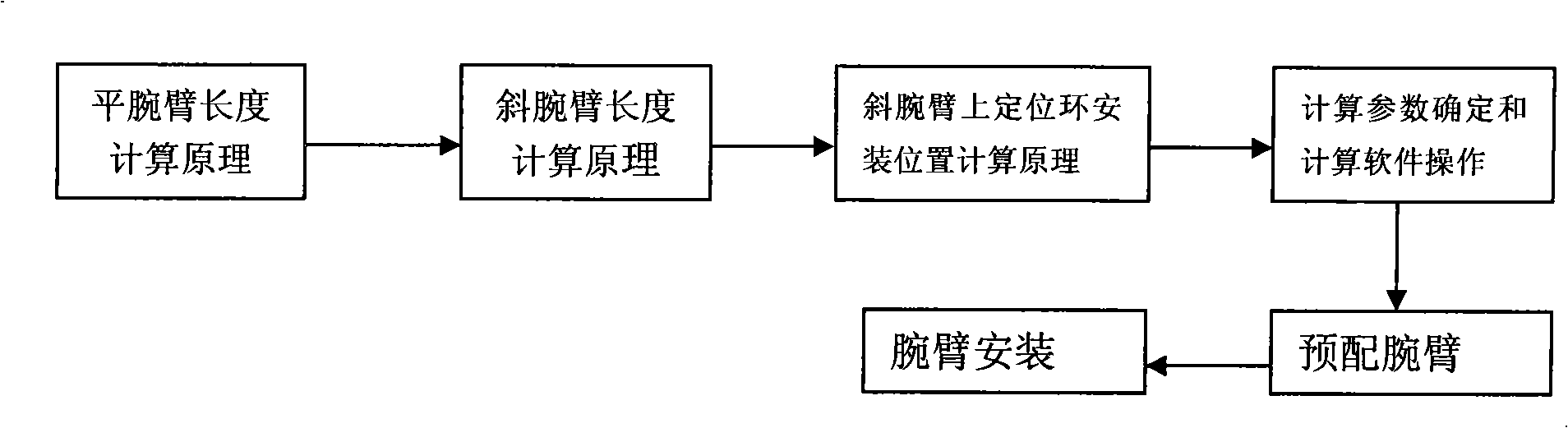

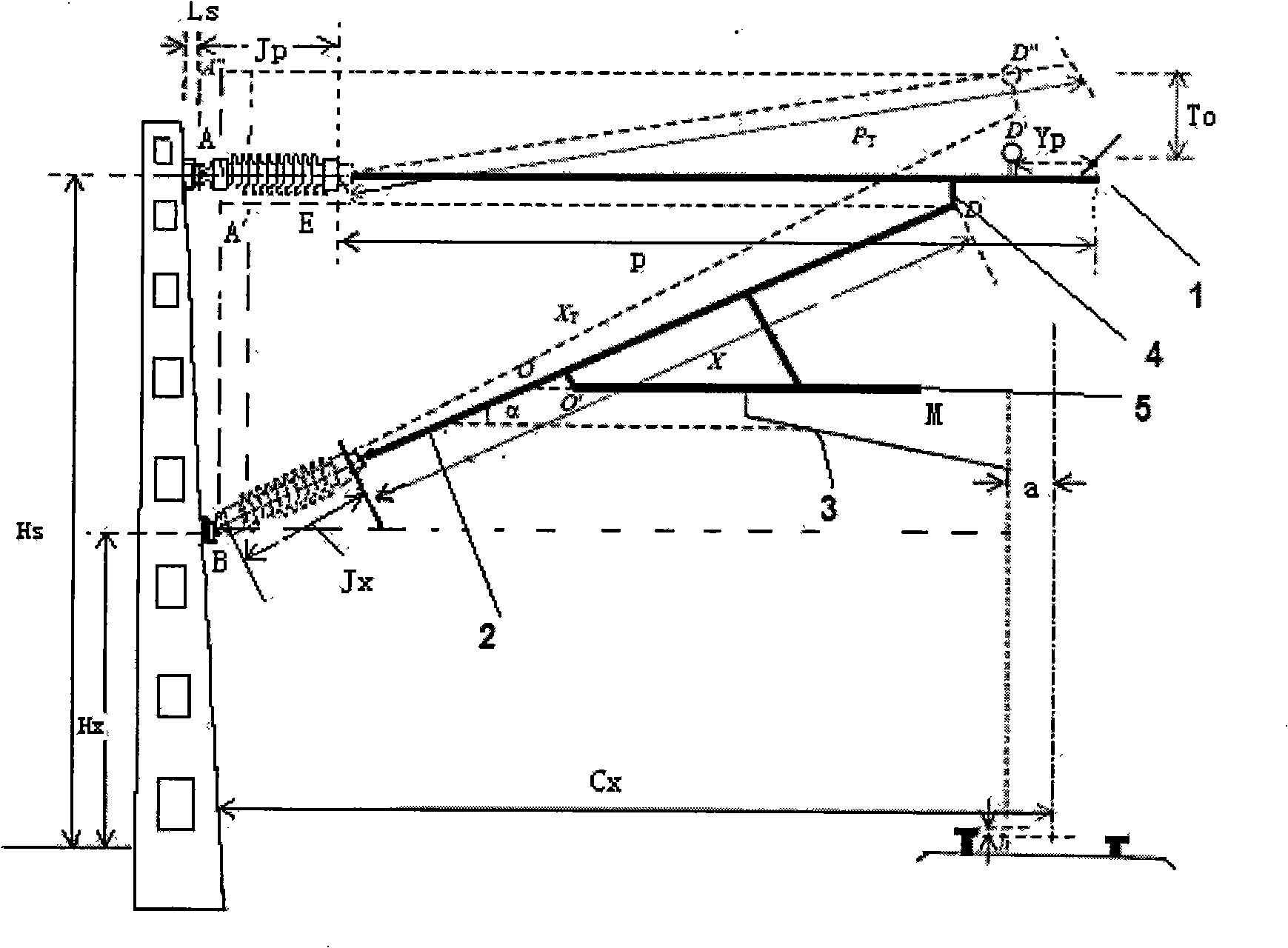

[0085] The present invention high-speed railway electrification catenary arm calculation and installation method, such as figure 1 As shown, it includes: calculation of the length of flat wrist arm 1, calculation of the length of the positioning tube of inclined wrist arm 2, calculation of the installation position of positioning ring 5 on the inclined wrist arm, pre-configuration of the wrist arm, and installation of the wrist arm.

[0086] The calculation of the length of the flat wrist 1 includes: the calculation of the length of the flat wrist 1 without raising and the calculation of the length of the flat wrist 1 with raising.

[0087] For the calculation of the flat wrist-arm length without raising, the following formula is used:

[0088] P=δ·H s / 1000+C x -h·G c / G k -a+Q z -J p -L s +Y p

[0089] The stated wrist-arm length with elevation, calculated using the following formula

[0090] P T = ...

Embodiment 2

[0144] The present invention high-speed railway electrification catenary arm calculation and installation method, such as figure 1 As shown, it includes: calculation of the length of flat wrist arm 1, calculation of the length of the positioning tube of inclined wrist arm 2, calculation of the installation position of positioning ring 5 on the inclined wrist arm, pre-configuration of the wrist arm, and installation of the wrist arm.

[0145] When the wrist arm is not raised, the calculation of the length of the flat wrist arm 1 adopts the following formula:

[0146] P=δ·H s / 1000+C x -h·G c / G k -a+Q z -J p -L s +Y p

[0147] The calculation of the length of the oblique arm 2 adopts the following formula:

[0148] X = L a 2 + L b 2 - Jx

[0149] Among them, La=δ·H x / 1000+C x -h·G c ...

Embodiment 3

[0165] The present invention high-speed railway electrification catenary arm calculation and installation method, such as figure 1 As shown, it includes: calculation of the length of flat wrist arm 1, calculation of the length of the positioning tube of inclined wrist arm 2, calculation of the installation position of positioning ring 5 on the inclined wrist arm, pre-configuration of the wrist arm, and installation of the wrist arm.

[0166] When the wrist arm is raised, the calculation of the length of the flat wrist arm 1 adopts the following formula:

[0167] P T = T G 2 + ( δ · H s / 1000 + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com