Method for preparing AgI/TiO2 nano compound photocatalyst

A photocatalyst and nano-composite technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low absorption coefficient, toxic dyes, self-degradation, etc., and achieve simple and economical preparation process The effect of stable energy and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] AgI / TiO 2 The preparation method of nanocomposite photocatalyst, it comprises the steps:

[0022] Weigh 0.188g LiI.3H 2 O (lithium iodide trihydrate), add 4ml of absolute ethanol and ultrasonically dissolve to obtain A solution; weigh 0.169g AgNO 3 And add 15ml of absolute ethanol and sonicate until dissolved, thus preparing solution B. Add solution A dropwise to solution B under magnetic stirring to produce a yellow precipitate. After stirring evenly, add 1ml of butyl titanate dropwise, heat and stir until nearly dry, continue stirring for 1h after cooling until completely dry, then add 8ml of anhydrous Ultrasonic dissolution of ethanol, adding 1ml of water under magnetic stirring, Buchner funnel suction filtration, washing, baking at 90°C for 2h, roasting at 450°C for 2h, heating rate 10°C / min, and natural cooling to obtain AgI / TiO 2 Nanocomposite photocatalysts.

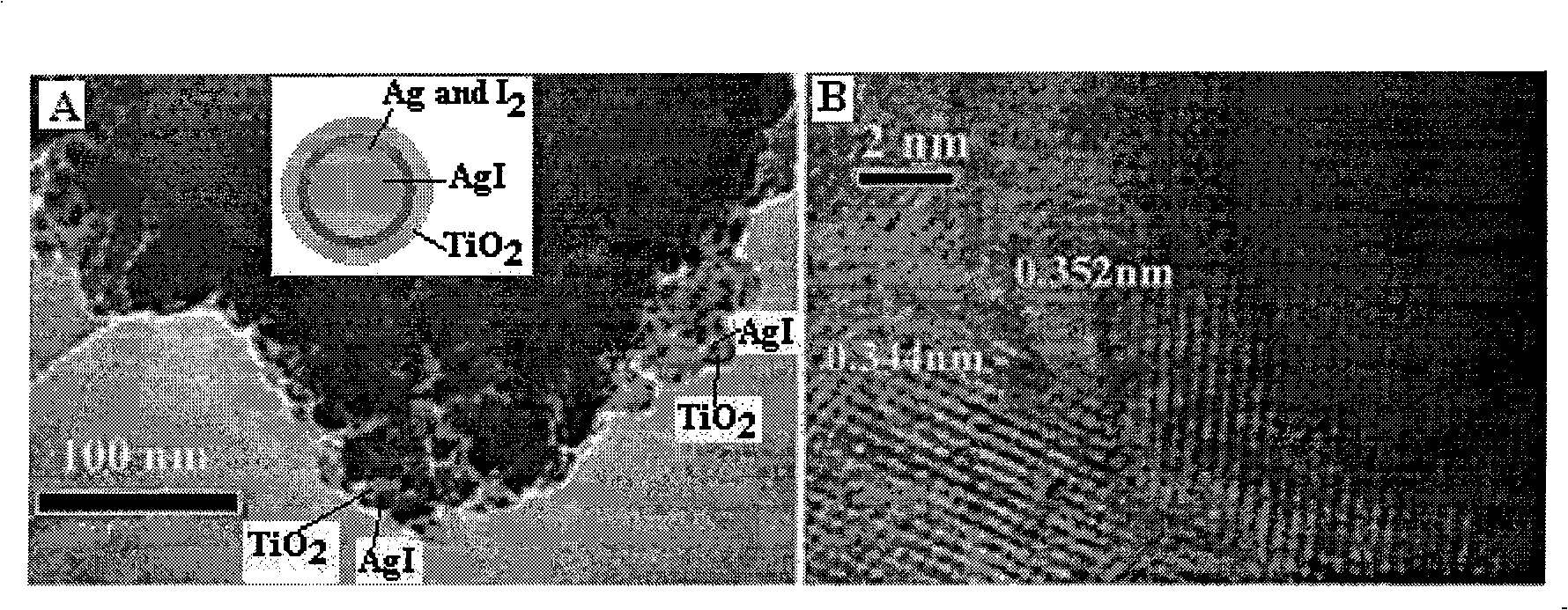

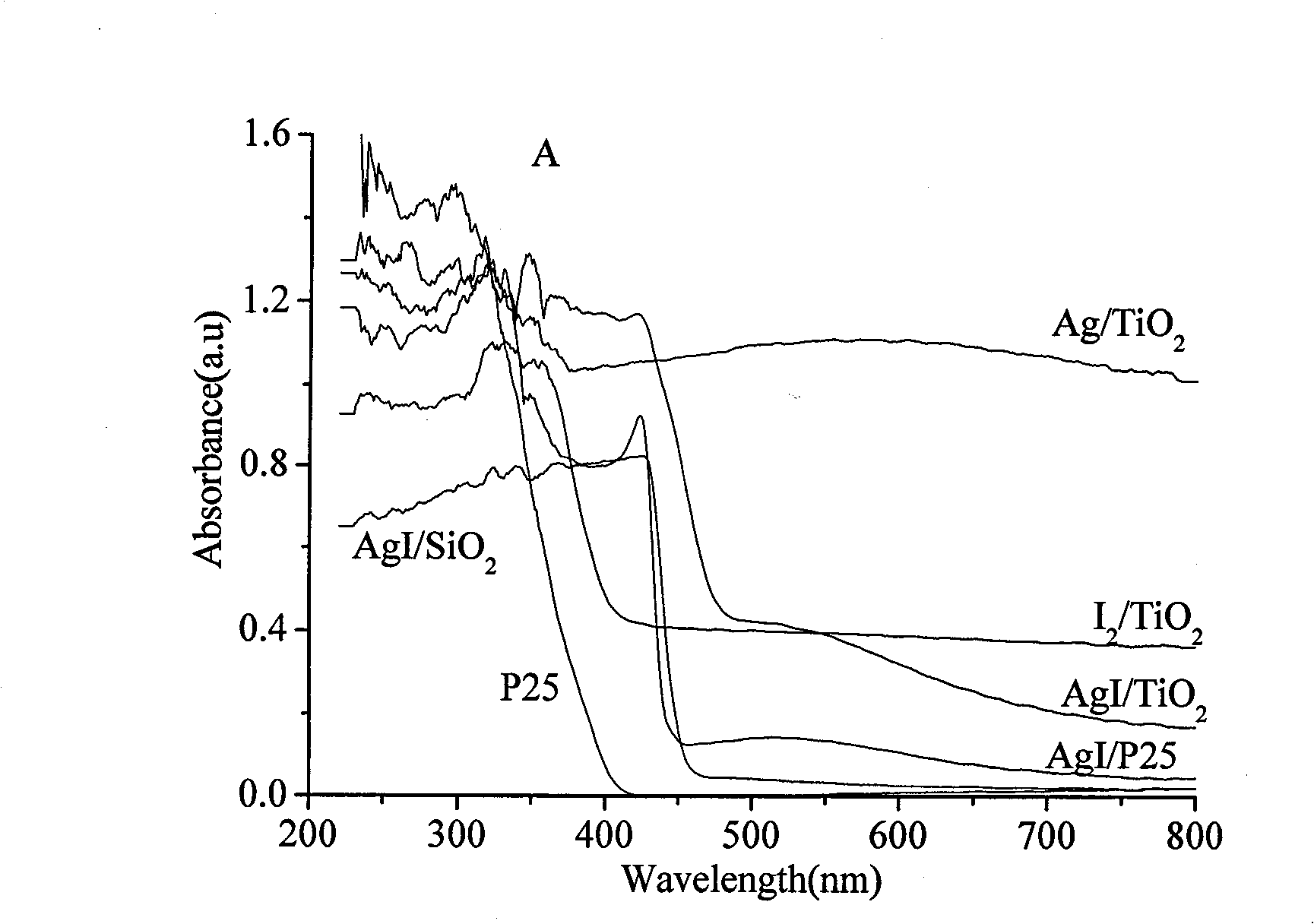

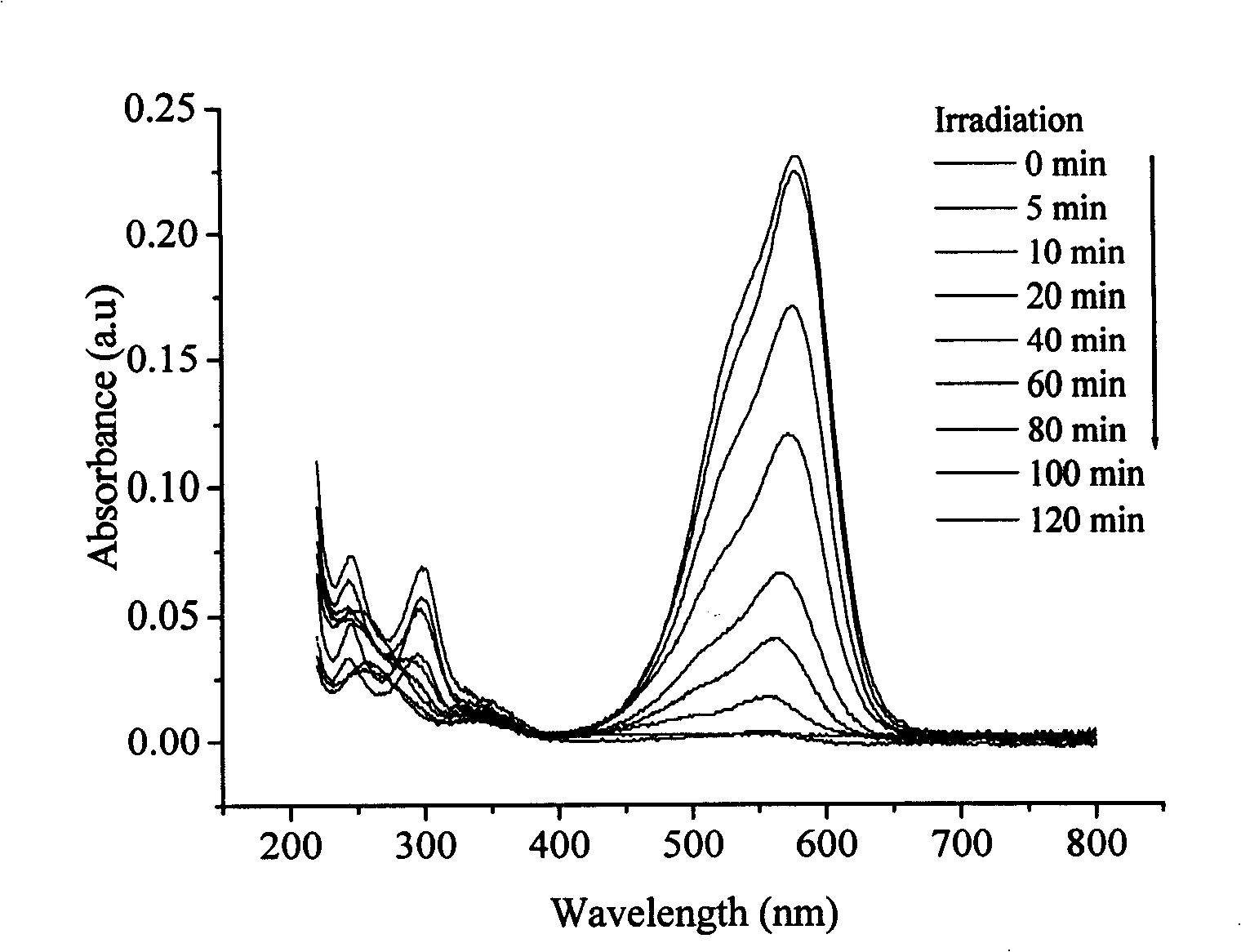

[0023] figure 1 , figure 2 Respectively, it is the TEM figure and the ultraviolet-visible light d...

Embodiment 2

[0040] AgI / TiO 2 The preparation method of nanocomposite photocatalyst, it comprises the steps:

[0041] 1) According to AgNO 3 The molar ratio to LiI is 1:1, and the following two raw materials are selected: (1) AgNO 3 , (2) LiI, standby;

[0042] 2) Add LiI into absolute ethanol and sonicate until dissolved to obtain A solution with a mass concentration of 1%;

[0043] AgNO 3 Add it into absolute ethanol and sonicate until dissolved to obtain a B solution with a mass concentration of 0.1%.

[0044] 3) Add solution A dropwise to solution B under magnetic stirring to produce a yellow precipitate. After stirring evenly, add butyl titanate dropwise; butyl titanate and AgNO 3 The mass ratio of is 5.9;

[0045] 4) Continue heating and stirring until nearly dry, continue stirring for 0.5h after cooling until completely dry, then add absolute ethanol to make the solid content in the resulting suspension to 5% (mass), ultrasonically disperse, add water under magnetic stirring, ...

Embodiment 3

[0047] AgI / TiO 2 The preparation method of nanocomposite photocatalyst, it comprises the steps:

[0048] 1) According to AgNO 3 with LiI.3H 2 The molar ratio of O is 1:1, and the following two raw materials are selected: (1) AgNO 3 , (2) LiI.3H 2 O, standby;

[0049] 2) LiI.3H 2 O was added to absolute ethanol and sonicated until dissolved to obtain a solution of A with a mass concentration of 10%;

[0050] AgNO 3 Add it into absolute ethanol and sonicate until dissolved to obtain a B solution with a mass concentration of 2%;

[0051] 3) Add solution A dropwise to solution B under magnetic stirring to produce a yellow precipitate. After stirring evenly, add butyl titanate dropwise; butyl titanate and AgNO 3 The mass ratio of is 61;

[0052] 4) Continue heating and stirring until nearly dry, continue stirring for 2 hours after cooling until completely dry, then add absolute ethanol to make the solid content of the resulting suspension 10%, ultrasonically disperse, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com