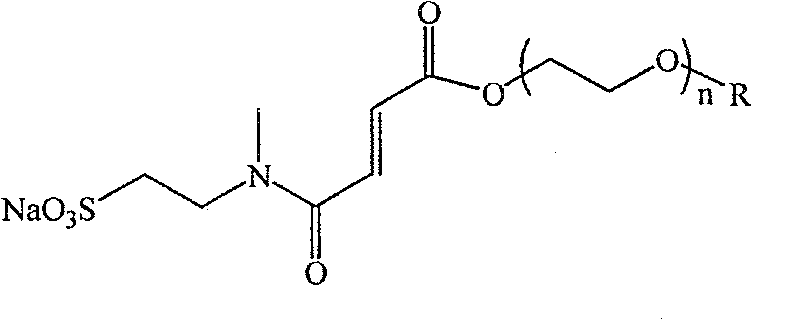

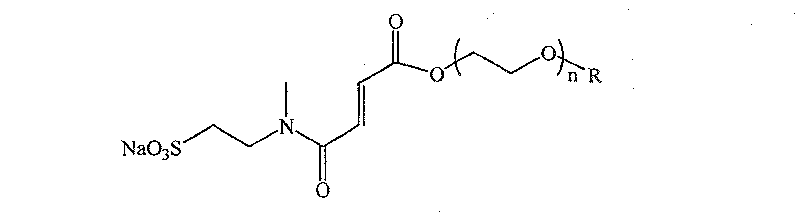

Boletic acid type polymerisable emulsifier containing negative ion and non-ionic group and preparation method thereof

A technology of non-ionic groups and polymeric emulsifiers, which is applied in the field of fumaric acid-type polymerizable emulsifiers and its preparation, can solve problems affecting the rheological properties and stability of latex liquids, polymer composition and performance changes, latex liquid freezing Solve problems such as poor melt stability, achieve excellent emulsification performance and polymerization stability, improve coating performance, and have good application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of N-methyl-N-dodecyl alcohol polyoxyethylene ether (7) monoester maleoyl-sodium taurine polymerizable emulsifier:

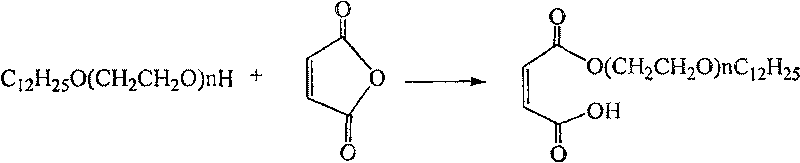

[0024] (1) Preparation of monolauryl polyoxyethylene maleate (7) ester from maleic anhydride and polyoxyethylene lauryl ether (7)

[0025] Synthesis steps: Weigh 0.05 mol of lauryl alcohol polyoxyethylene ether (7), add 0.05 mol of maleic anhydride into a three-necked flask, heat and stir until the maleic anhydride melts, raise the temperature to 70-100°C, and react for 3-5 hours.

[0026] (2) Monolauryl alcohol polyoxyethylene ether (7) monoester fumaryl chloride is prepared by reacting lauryl polyoxyethylene ether (7) ester with phosphorus trichloride

[0027] Synthesis steps: Weigh 0.05mol monododecyl alcohol polyoxyethylene ether (7) maleate into a three-necked flask, raise the temperature to 40-70°C, slowly add 0.025mol phosphorus trichloride dropwise, and drop it at 40-70°C React at 70°C. After the reaction is finished, fumaryl chlorid...

Embodiment 2

[0032] Preparation of N-methyl-N-tetradecyl polyoxyethylene ether (3) monoester maleoyl-sodium taurine polymerizable emulsifier:

[0033] (1) Preparation of monotetradecyl polyoxyethylene maleate (3) ester from maleic anhydride and myristyl polyoxyethylene ether (3)

[0034] Synthesis steps: Weigh 0.05 mol of tetradecyl alcohol polyoxyethylene ether (3), add 0.05 mol of maleic anhydride into a three-necked flask, heat and stir until the maleic anhydride melts, raise the temperature to 70-90°C, and react for 2-3 hours. A colorless or pale yellow liquid product was obtained.

[0035] (2) Preparation of tetradecyl alcohol polyoxyethylene ether (3) monoester fumaryl chloride by reacting monotetradecyl alcohol polyoxyethylene ether (3) ester with phosphorus trichloride

[0036] Synthesis steps: Weigh 0.05mol monotetradecyl alcohol polyoxyethylene ether (3) maleate in a three-necked flask, raise the temperature to 40-70°C, slowly add 0.025mol phosphorus trichloride dropwise, and drop...

Embodiment 3

[0041] Preparation of N-methyl-N-dodecyl alcohol polyoxyethylene ether (15) monoester maleoyl-sodium taurine sulfonate polymerizable emulsifier:

[0042] (1) Preparation of monolauryl polyoxyethylene maleate (15) ester from maleic anhydride and polyoxyethylene lauryl ether (15)

[0043] Synthesis steps: Weigh 0.05 mol of lauryl alcohol polyoxyethylene ether (15), add 0.05 mol of maleic anhydride into a three-necked flask, heat and stir until the maleic anhydride melts, raise the temperature to 70-100°C, and react for 3-5 hours.

[0044] (2) Preparation of dodecyl alcohol polyoxyethylene ether (15) monoester fumaryl chloride by reacting monolauryl alcohol polyoxyethylene ether (15) ester with phosphorus trichloride

[0045] Synthesis steps: Weigh 0.05mol monododecyl alcohol polyoxyethylene ether (15) maleate in a three-necked flask, raise the temperature to 40-70°C, slowly add 0.025mol phosphorus trichloride dropwise, and drop it at 40-70°C. React at 70°C. After the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com