High-efficient energy-saving electric roaster

A high-efficiency, energy-saving, electric oven technology, applied in roaster/barbecue grids, kitchen utensils, home utensils, etc., can solve the problems of difficult to achieve uniform baking, uncontrollable baking effect, limited food, etc., to prevent heat Loss, improve baking efficiency, save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

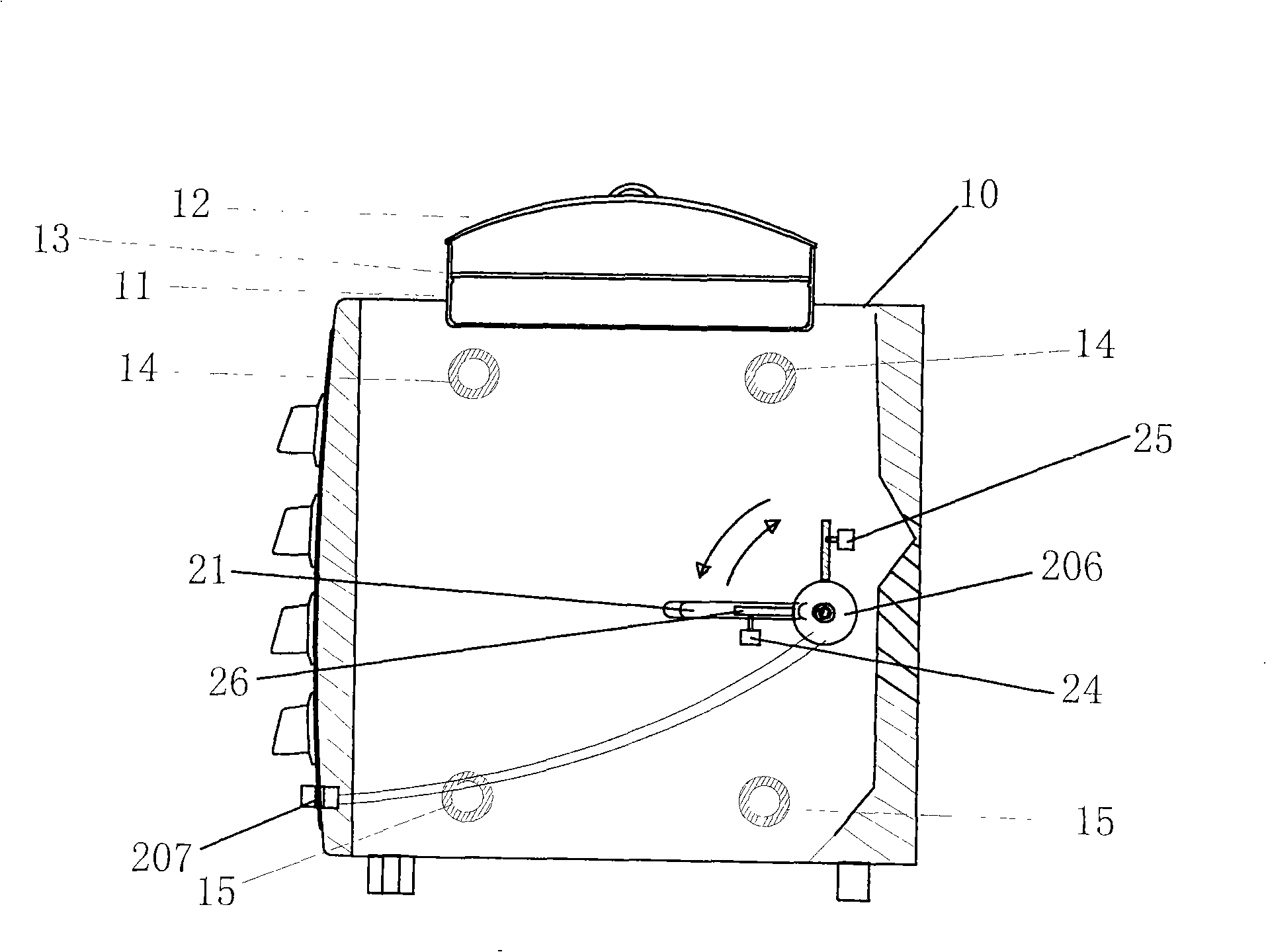

[0016] Such as Figure 1-8 , the present invention includes an electric oven body 10, an oven door 8 and a control panel, an upper electric heating tube 14 and a lower electric heating tube 15 are respectively provided at the top and bottom of the cavity inside the electric oven body 10, and the cavity of the electric oven body 10 There is also a rotatable electric heating tube assembly 20 at the rear of the body, which includes a rotating electric heating tube 21 and a synchronous motor 206 that can change its position by rotating around both ends. The two ends of 21 extend horizontally out of the left and right side panels in the cavity of the electric oven body 10, and one end thereof is connected with the synchronous motor 206 through the runner 202, and a cross bar 23 is also connected on the rotating electric heating tube 21 or the runner 202. Two micro switches 24 and 25 are provided on both sides of the inner wall of the electric oven body 10 cavity where the electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com