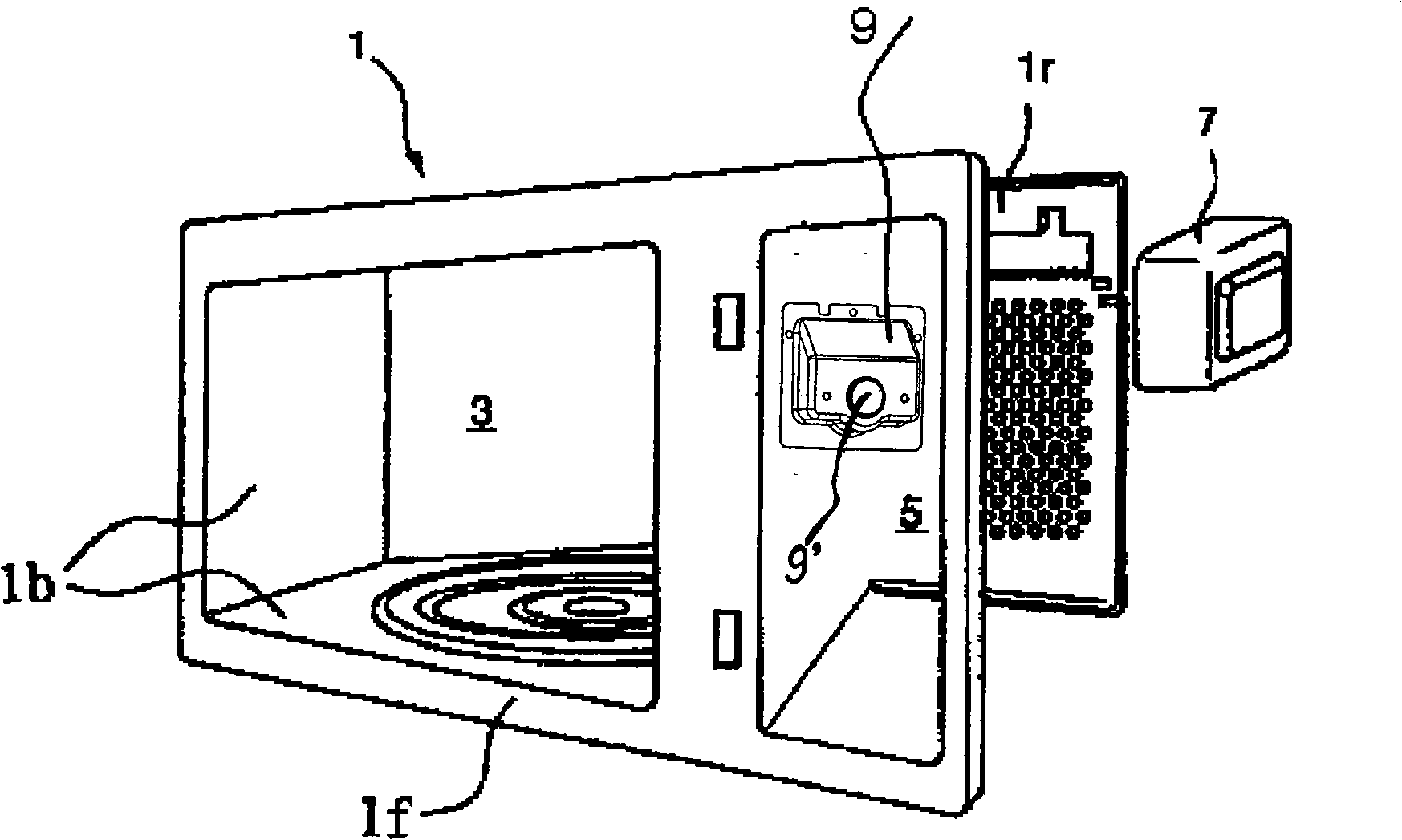

Wave guide structure of microwave oven

A waveguide structure and microwave oven technology, applied in the field of microwave ovens, can solve the problems of magnetron damage, high microwave reflection coefficient, magnetron heating, etc., and achieve the effect of improving feedback aggregation and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical characterictic that the present invention is identical with prior art is no longer described in detail below:

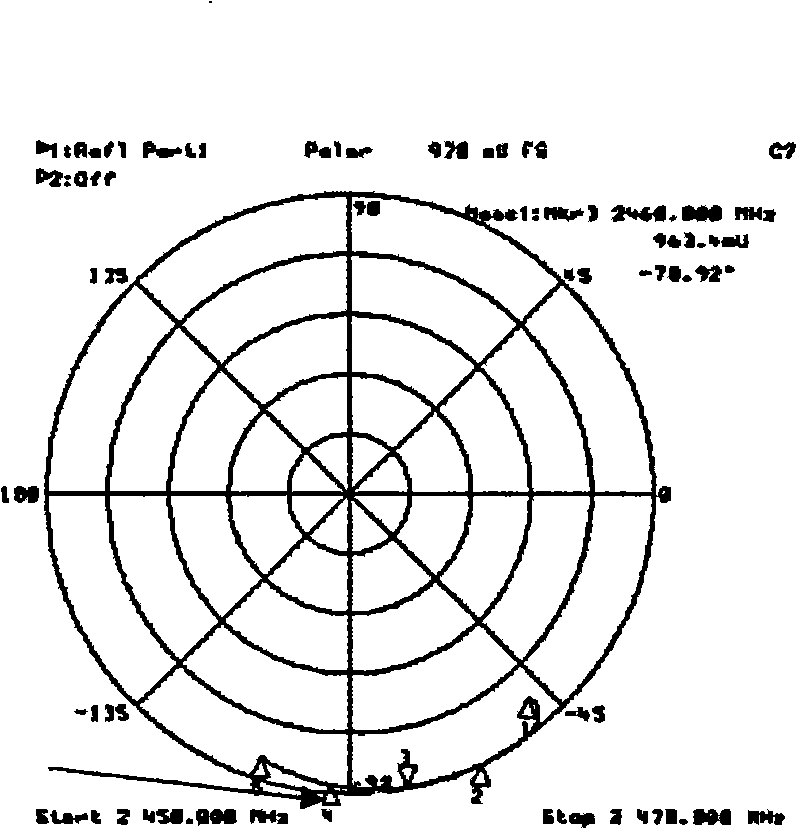

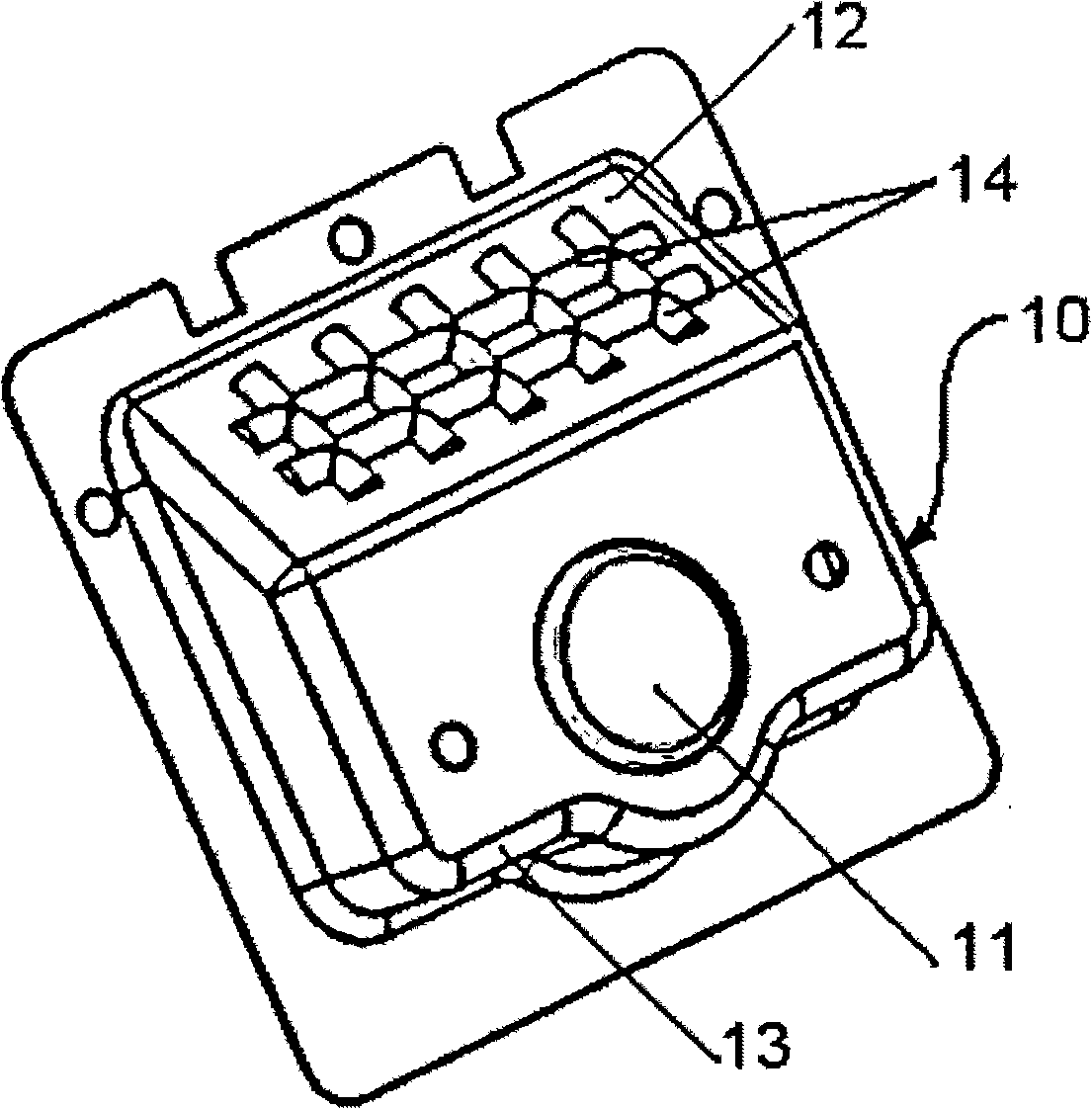

[0017] Such as image 3 and Figure 4 As shown, the waveguide structure of the microwave oven of the present invention includes a magnetron insertion port 11 for inserting the antenna of the magnetron into the waveguide 10, an inclined top wall 12 and a U-shaped lower wall 13, and the U-shaped lower wall Wall 13 is shorter than inclined top wall 12, and is parallel to antenna, and waveguide 10 is formed with the passageway that guides microwave in it, makes the microwave that produces on the magnetron of electric control room can pass to cooking through the outlet of waveguide. Inside the chamber, the inclined top wall 12 of the waveguide 10 is provided with a groove 14, the groove 14 can reflect the microwave, and the reflection coefficient is about 0.75 according to the schematic diagram of the microwave reflection impedance. The grooves 14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com