Electrostatic driven F-P cavity MEMS wavelength tunable filter

An electrostatic drive, electrostatic drive technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of wide beam drop, filter efficiency selection, light utilization rate drop, thickness inconsistency, etc., to achieve the effect of improving filter efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

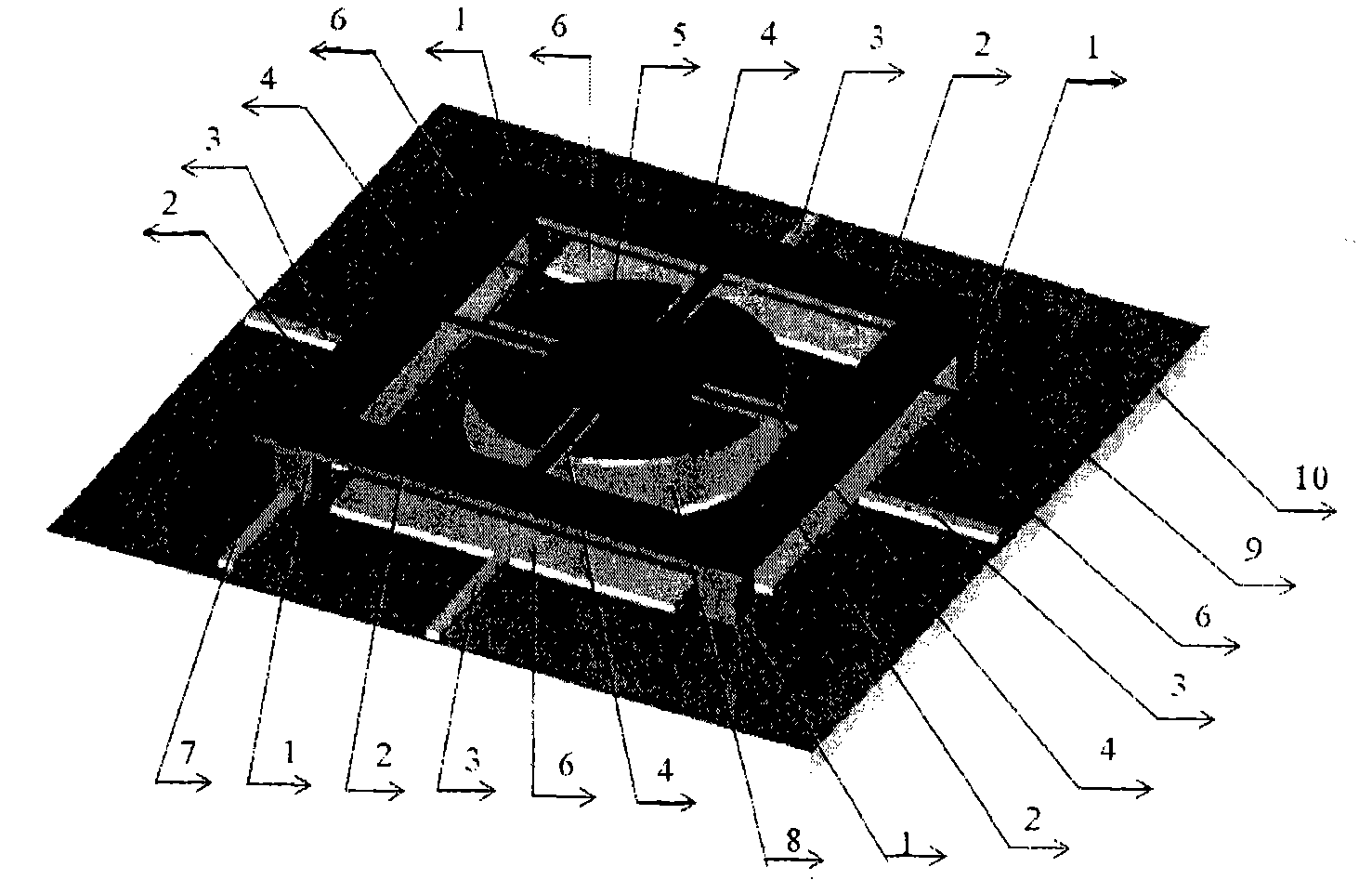

[0019] In this embodiment, an electrostatically driven F-P cavity MEMS wavelength tunable filter with a radius of 100 μm in both the front cavity surface and the rear cavity surface is taken as an example, and the present invention is described in detail with reference to the accompanying drawings.

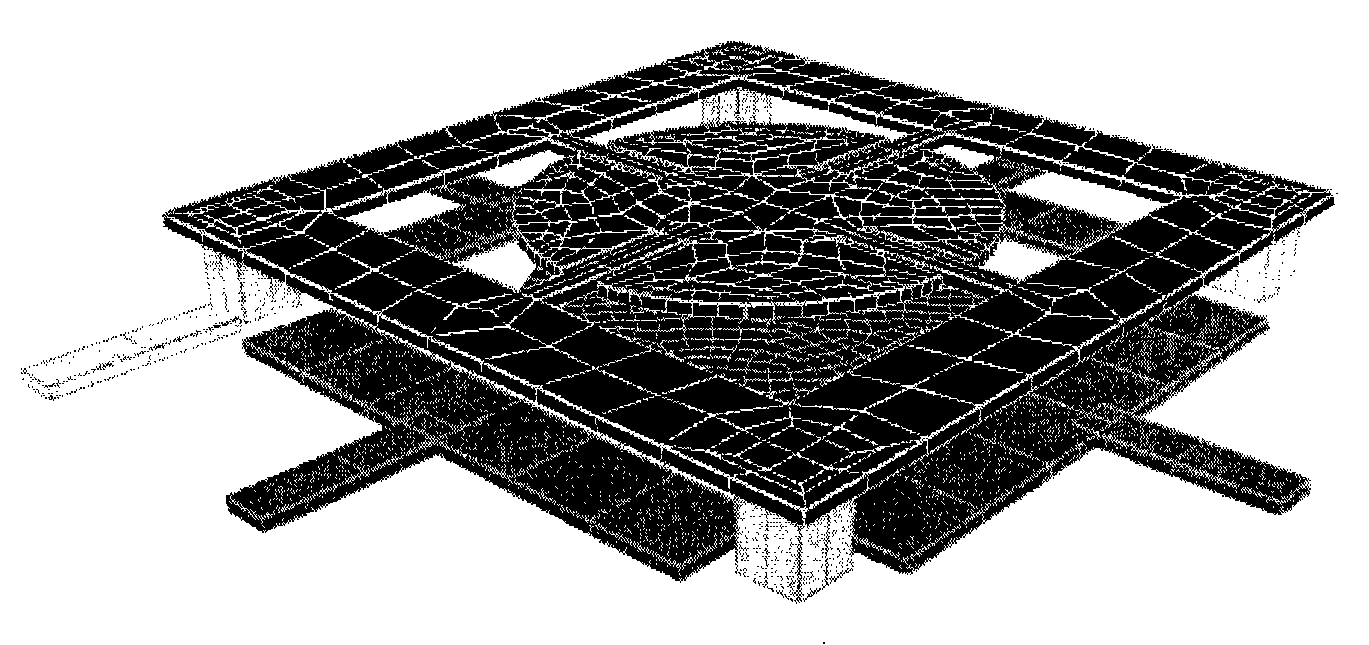

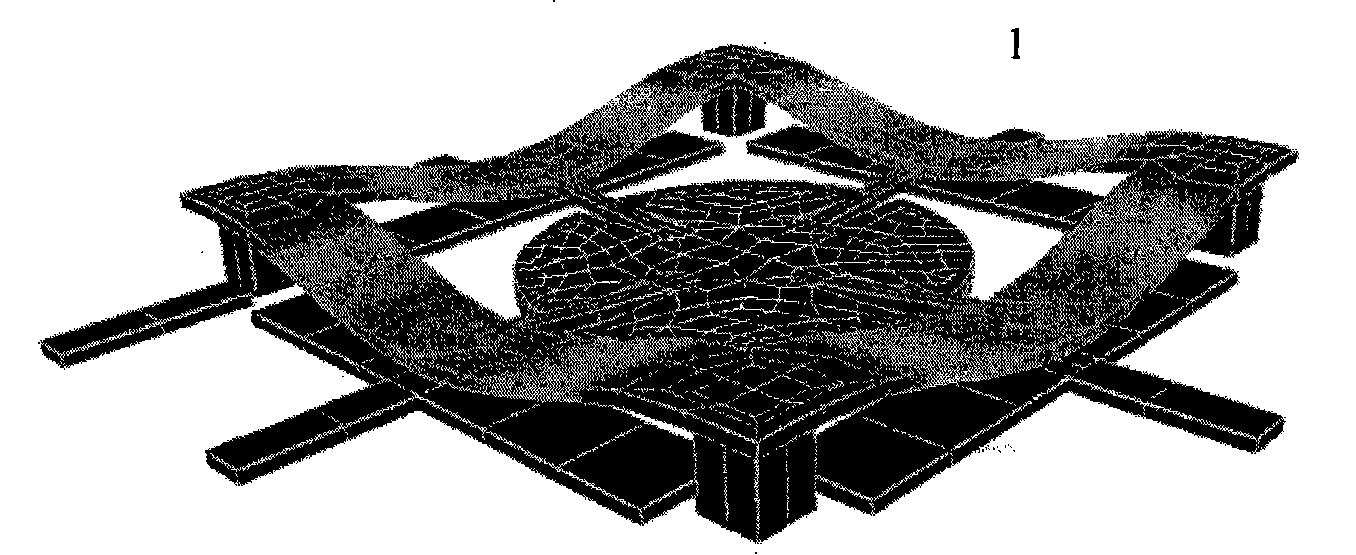

[0020] figure 1 It is a three-dimensional schematic diagram of an electrostatically driven F-P cavity MEMS wavelength tunable filter of this embodiment; An insulating layer 9 is grown on it to separate the silicon substrate 10 from the electrostatically driven F-P cavity MEMS wavelength tunable filter, and the material of the insulating layer 9 can be silicon dioxide or silicon nitride; the electrostatically driven F-P cavity MEMS wavelength of the present embodiment The F-P cavity in the adjustable filter is located in the center of the whole s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com