Polystyrene insulating brick and its production method and use method

A technology of polystyrene and thermal insulation bricks, which is applied in building structures, building components, buildings, etc., can solve the problems of high cost and complicated manufacturing process, and achieve the effects of slow heat dissipation, simple construction process, and convenient material selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1 Insulation brick structure

[0021] The present invention is a polystyrene heat preservation brick. The heat preservation bricks are all made of polystyrene material. The heat preservation brick is a three-dimensional structure. There is at least one horizontal threading hole on the surface, the upper and lower surfaces of the insulation bricks are respectively set as convex and concave block sills, and the left and right surfaces of the insulation bricks are respectively respectively set as convex and concave block sills.

[0022] The through hole of the column is circular or polygonal.

[0023] The polystyrene is foamed flame-retardant or extruded flame-retardant polystyrene.

Embodiment 2

[0024] Example 2 Manufacture of insulation bricks

[0025] Using polystyrene as raw material, add 0.001-0.008% sodium bicarbonate, 0.001-0.005% organic acid, 0.005-0.01% mixture of ketones and alcohols, 0.0015-0.004% talcum powder, 15 -20% freon foaming agent and various pigments are injected into the insulation brick mold after batching, heated and extruded once to form polystyrene insulation bricks.

Embodiment 3

[0026] Example 3 Use of insulation bricks

[0027] The insulation bricks manufactured in Example 2 do not need to be bonded with cement concrete, and are directly built through the convex and concave blocks of the insulation bricks, pouring reinforced concrete into the through holes of the columns, and penetrating steel bars in the horizontal threading holes, which are used in building 5 Walls of buildings with one or less floors.

[0028] The invention utilizes a forming mold to produce polystyrene insulation bricks, which has simple process and low cost, and achieves good effects of energy saving and emission reduction. Walls of buildings with 5 or less floors.

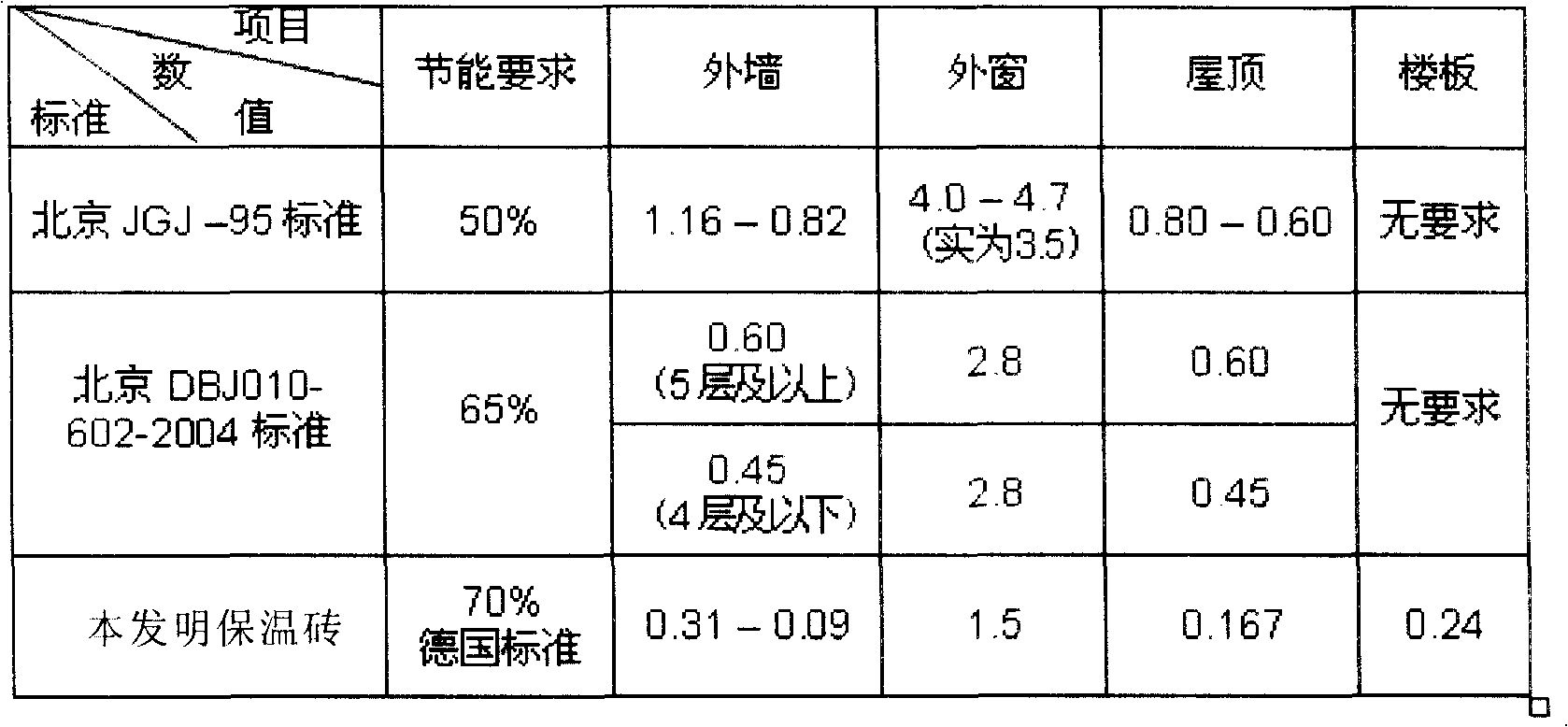

[0029] The present invention adopts polystyrene as raw material, adds auxiliary material and polymer, heats, injects catalyst at the same time, and makes foamed flame-retardant polystyrene (EPS) or extruded flame-retardant polystyrene (EPS) through foaming or extrusion technology. Polystyrene (XPS), when the insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com