Clothes drying machine and double-layer washing dehydration and baking integrated machine

A dryer and all-in-one technology, which is applied to other washing machines, household clothes dryers, washing machines with containers, etc., can solve the problems of cumbersome work, high labor intensity, and low utilization rate of heat energy, and reduce the volume of the machine , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

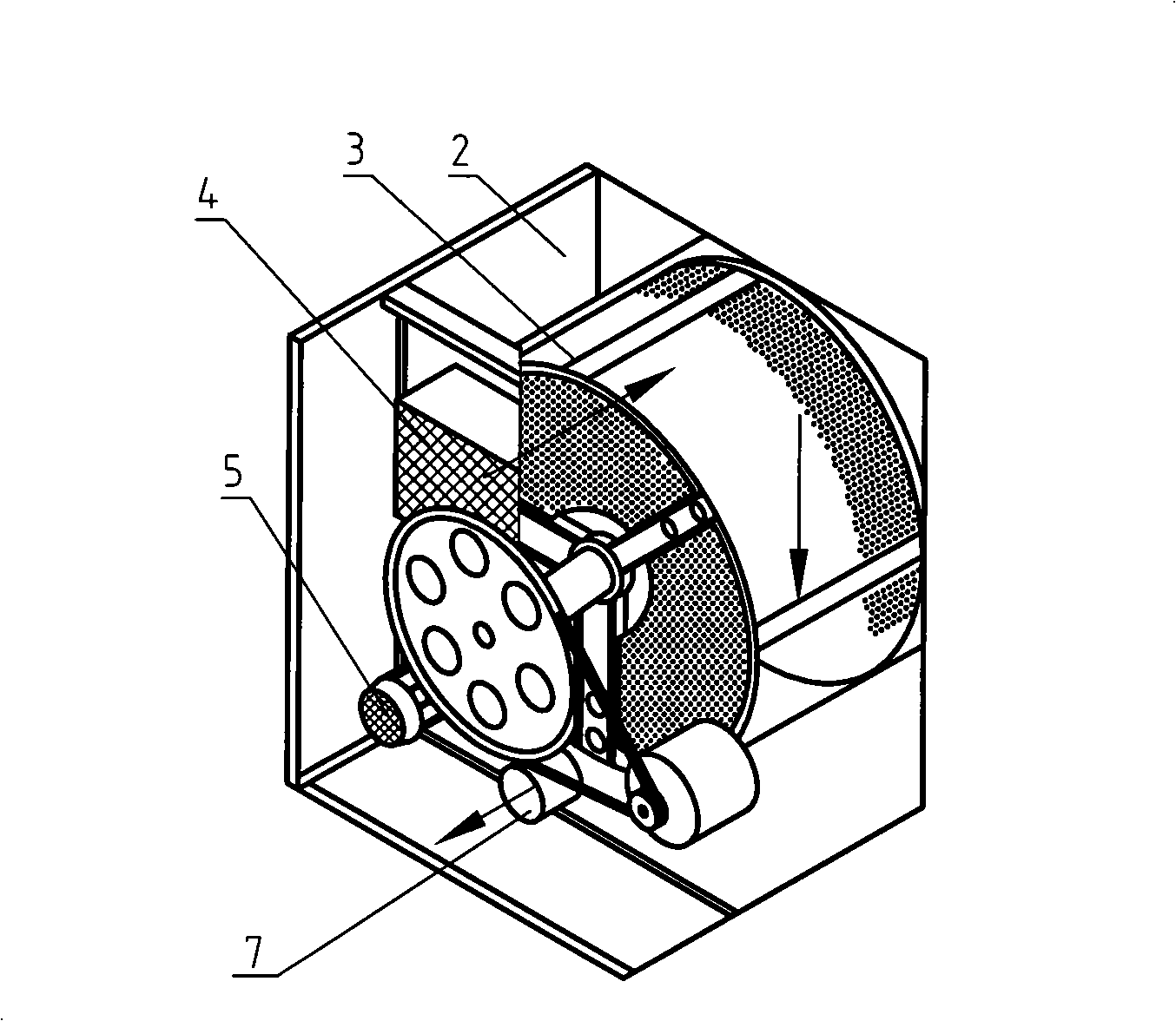

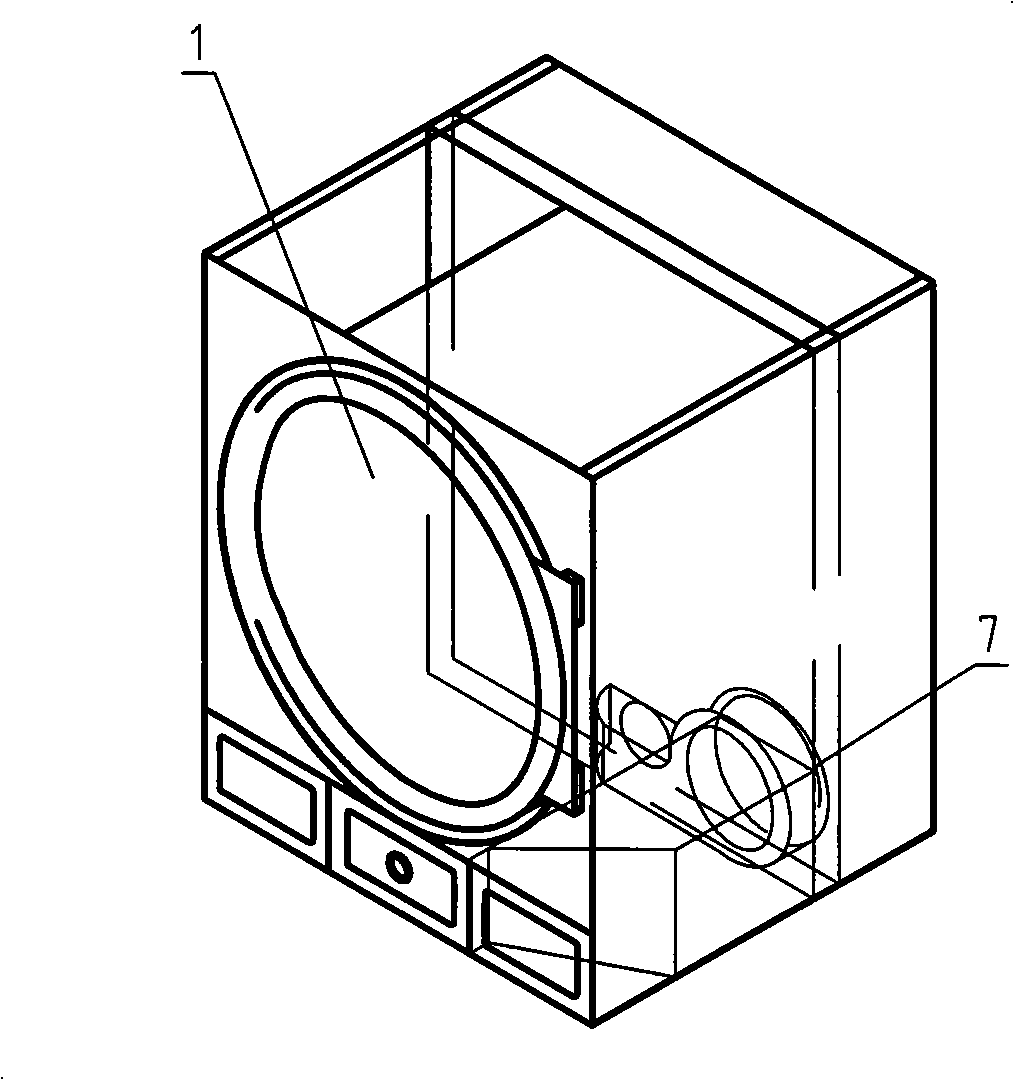

[0020] Such as figure 1 , figure 2 As shown, a clothes dryer includes a square dryer box 2, a drum 3 and its transmission, a heater 4 for providing drying heat, and an exhaust device consisting of a fan 5 and an air duct 7. The fan motor and drum motor are respectively located in the gap between the drum and the left and right lower corners. The door 1 of the dryer is connected with the box body 2 through hinges; the drum 3 is set in the box body 2, and the rear end plate is evenly distributed with punched air inlet holes, and the front part of the drum peripheral wall is equipped with evenly distributed air outlet holes , the front port of the air duct communicating with the outside is provided in the middle part below the drum, which communicates with the air outlet hole of the air duct, and then connects the air duct 7 and the fan 5, and the air duct 7 passes through the fan 5 from the side to the back of the drum 3 The bottom of the side, that is, the lower rear part of...

Embodiment 2

[0022] Figure 3, Figure 4, Figure 5 As shown, a double-layer eluting and drying integrated machine includes a frame, a drying part and an eluting part. The drying part is arranged on the upper part of the eluting part. Together. Wherein, the drying part includes a square dryer box 2, a drum 3 and a transmission device, a heater 4 for providing drying heat, and an exhaust device composed of a fan 5 and an air duct 7. The fan motor and drum motor are respectively located in the gap between the drum and the left and right lower corners. The door 1 of the dryer is connected with the box body 2 through hinges; the drum 3 is set in the box body 2, and the rear end plate is evenly distributed with punched air inlet holes, and the front part of the drum peripheral wall is equipped with evenly distributed air outlet holes , the front port of the air duct communicating with the outside is provided in the middle part below the drum, which communicates with the air outlet hole of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com