Process for recovering white slime and tunnel type calcining kiln for the method

A recycling method and calcining kiln technology, which are applied in furnaces, lime production, ceramic material production, etc., can solve the problems that light calcium technology is difficult to be popularized and used, high brick strength requirements, and reduced white mud recycling times, etc. The effect of high degree of automation, wide energy adaptability and high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

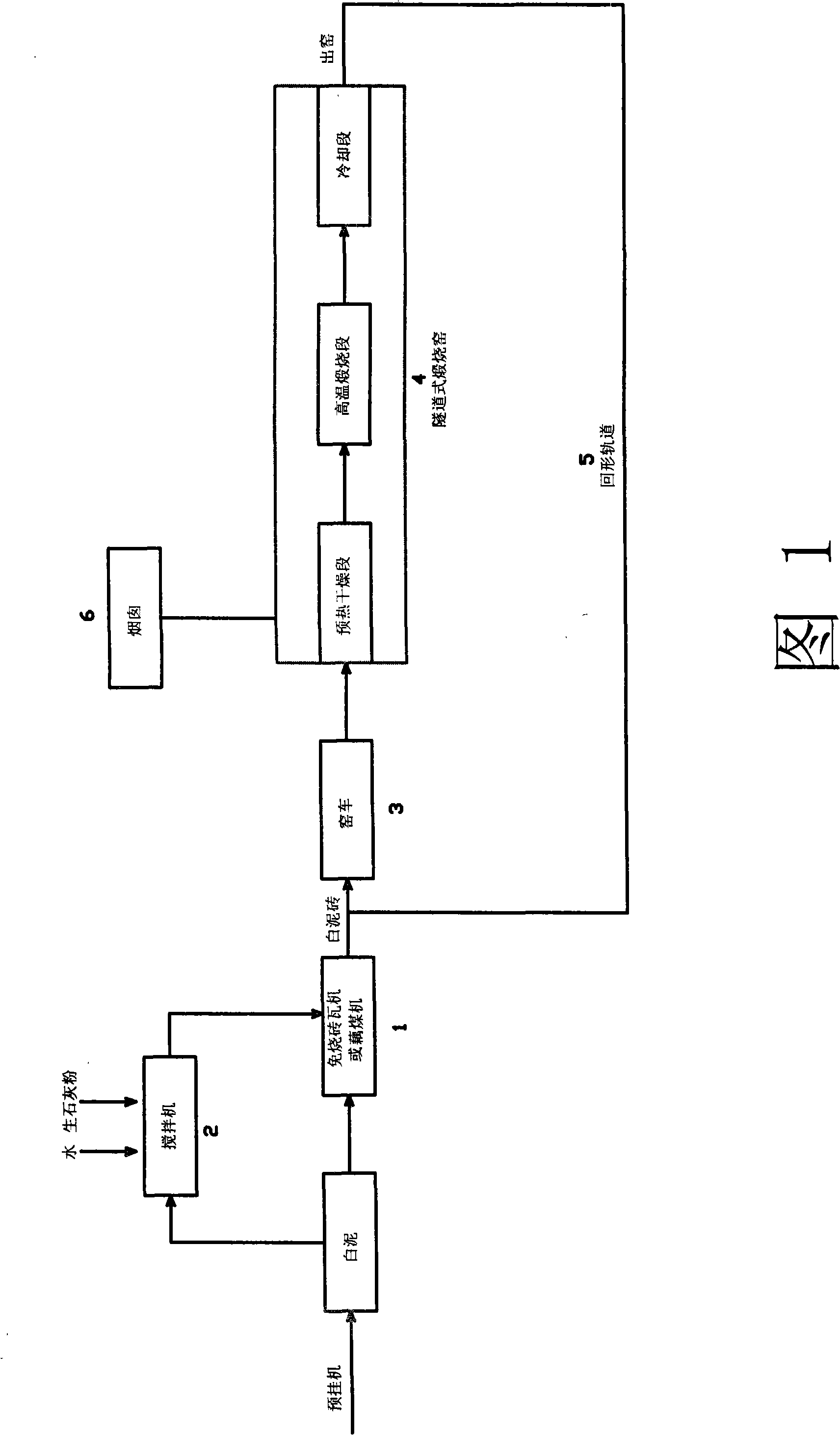

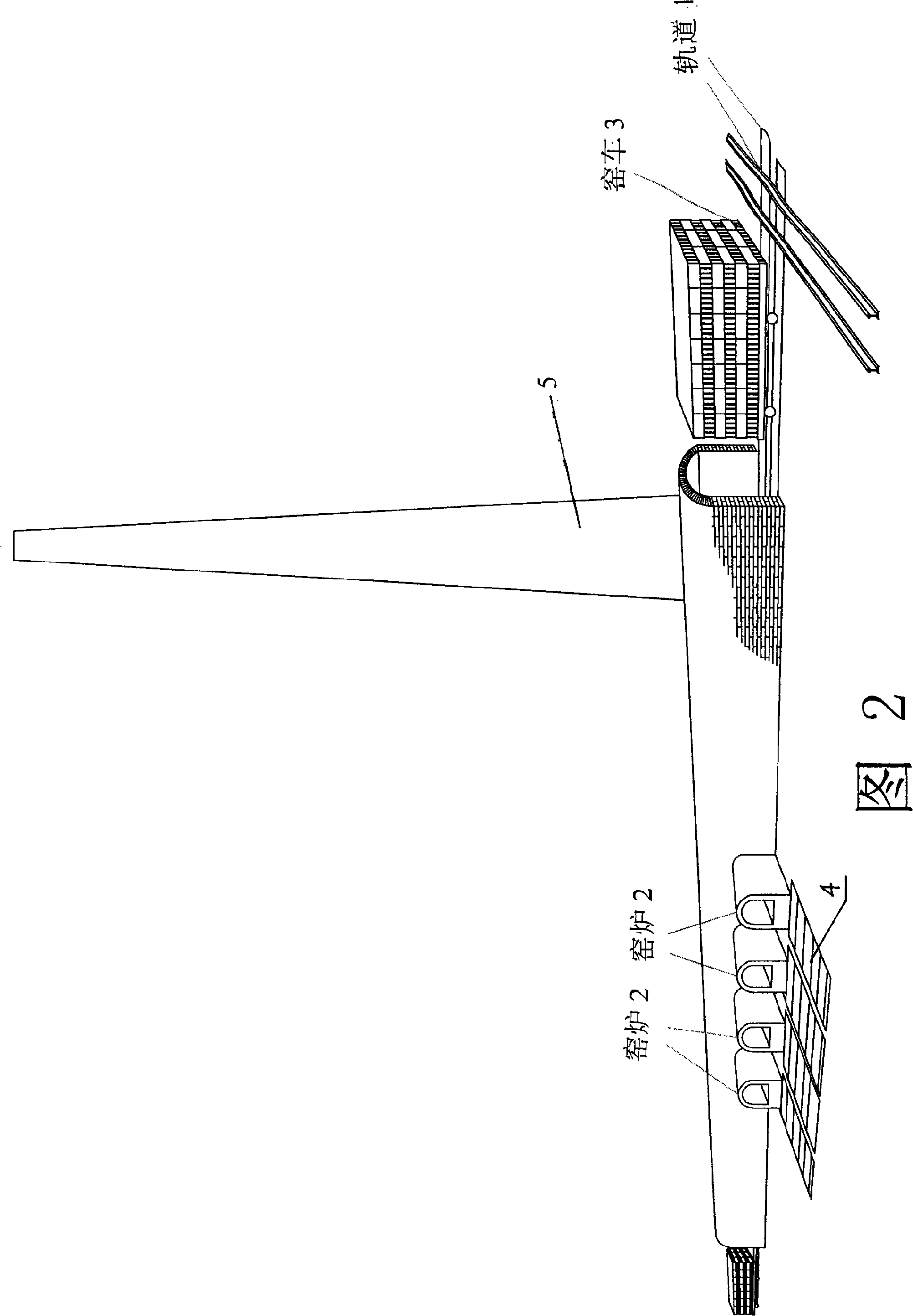

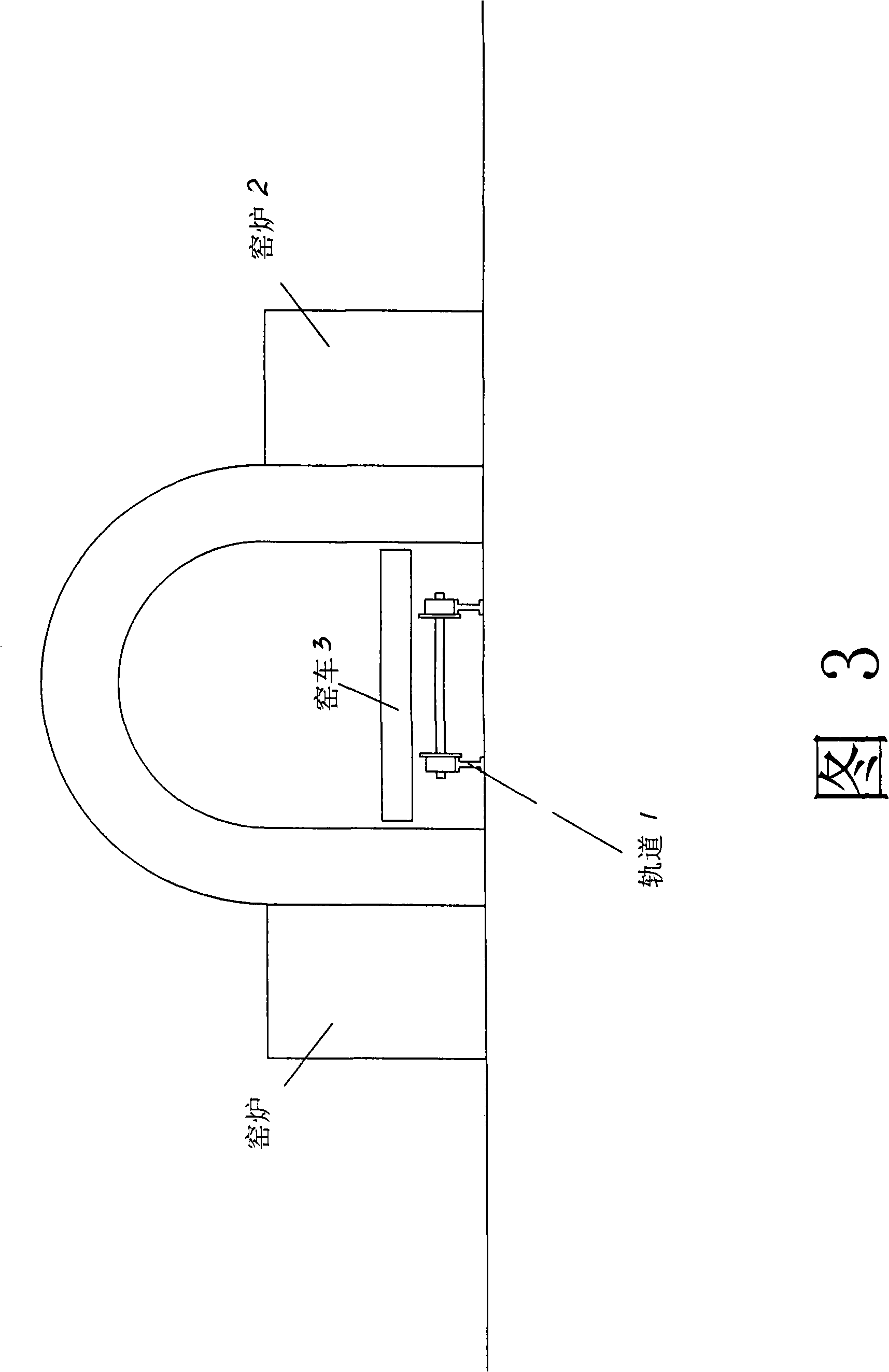

[0029] Combined with the accompanying drawings, the process flow of the lime mud recovery method: send the lime mud from the pre-hanging machine that meets the dryness requirement (dryness 65%-70%) to the unburned brick machine or the special lotus root coal machine to make bricks, and the dryness is lower than 65% white mud is sent into the mixer and mixed with a certain amount of quicklime powder to absorb excess water in the white mud, so that the dryness of the white mud can reach 65%-70%; if the dryness is higher than 80%, an appropriate amount of water can be added Adjust to make it meet the requirements of brick making. The finished bricks are stacked on the flat kiln car, and then the kiln car full of lime bricks is pushed into the tunnel calciner with a car. After preheating and drying, high temperature calcination, and cooling, the finished lime is released from the kiln. , can be used in the causticizing process, so that it can be used repeatedly.

[0030] The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com