Method for treating waste water from acetic acid mercapto- isooctyl ester

A technology of isooctyl thioglycolate and isooctyl acetate, which is applied in the field of wastewater treatment of isooctyl thioglycolate production, can solve the problems of difficult treatment, air pollution, and no patent reports, etc., and achieve simple process and effective treatment Obvious and easy to promote effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

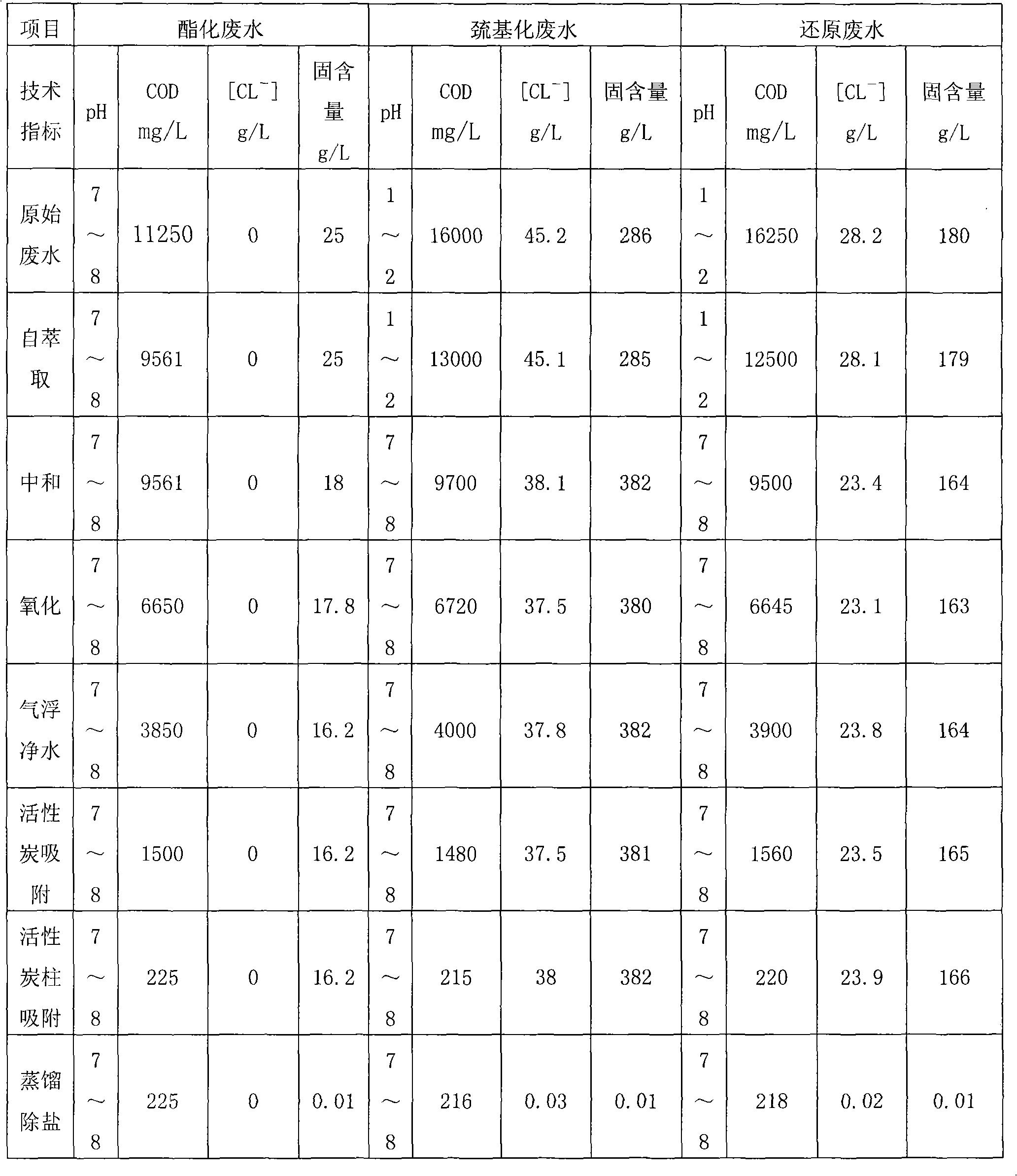

example 1

[0013] Example 1: Take 1L of esterification wastewater, the main pollutants are sodium sulfate, sodium carbonate and organic matter, the pH value of the wastewater is 7-8, the COD is 11250mg / L, and the solid content is 25g / L. Put the waste water in the separatory funnel, after standing still for 24-48 hours, the waste water is divided into two layers, the upper layer is the organic layer, and the lower layer is the waste water layer, recover the upper organic layer, and collect the lower waste water. According to 1% of the weight of wastewater collected in the lower layer, input H 2 o 2 Carry out oxidation treatment for 2 hours, then perform air flotation purification on the oxidized wastewater, and then put the wastewater after air flotation purification into powdered activated carbon according to 1% of the wastewater weight, mix and stir for 30 minutes, and then filter through plate and frame Machine filtration for decolorization and adsorption, after which the wastewater i...

example 2

[0014] Example 2: Take 1L of thiolated waste water, the main pollutants are sodium chloride, sodium sulfate, hydrochloric acid, organic matter, the pH value of the waste water is 1~2, and the COD is 16000mg / L, [CL - ]=45.2g / L, solid content 286g / L. Put the waste water in the separatory funnel, after standing still for 24-48 hours, the waste water is divided into two layers, the upper layer is the organic layer, and the lower layer is the waste water layer, recover the upper organic layer, and collect the lower waste water. Put the collected wastewater from the lower layer into quicklime and stir it for neutralization treatment until the pH value of the wastewater reaches 7-8, then let it stand for 6 hours, collect the wastewater from the upper layer, and add H 2 o 2 Carry out oxidation treatment for 2 hours, then perform air flotation purification on the oxidized wastewater, and then put the wastewater after air flotation purification into powdered activated carbon according ...

example 3

[0015] Example 3: Take 1L of reduced waste water, the main pollutants are zinc chloride, hydrochloric acid, sodium chloride, sodium carbonate and organic matter, the pH value of the waste water is 1~2, and the COD is 16250mg / L, [CL - ]=28.2g / L, solid content 180g / L. Put the waste water in the separatory funnel, after standing still for 24-48 hours, the waste water is divided into two layers, the upper layer is the organic layer, and the lower layer is the waste water layer, recover the upper organic layer, and collect the lower waste water. Put the collected wastewater from the lower layer into liquid ammonia and stir it for neutralization treatment until the pH value of the wastewater reaches 7-8, then let it stand for 6 hours, collect the wastewater from the upper layer, and add H 2 o 2 Carry out oxidation treatment for 2 hours, then perform air flotation purification on the oxidized wastewater, and then put the waste water after air flotation purification into powdered act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com