Screen printing equipment and printing system having the same

A technology of screen printing device and squeegee, applied in screen printing machines, general parts of printing machinery, printing and other directions, can solve problems such as difficulty in correct input, achieve stable printing film thickness, ensure printing thickness, prevent long longevity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

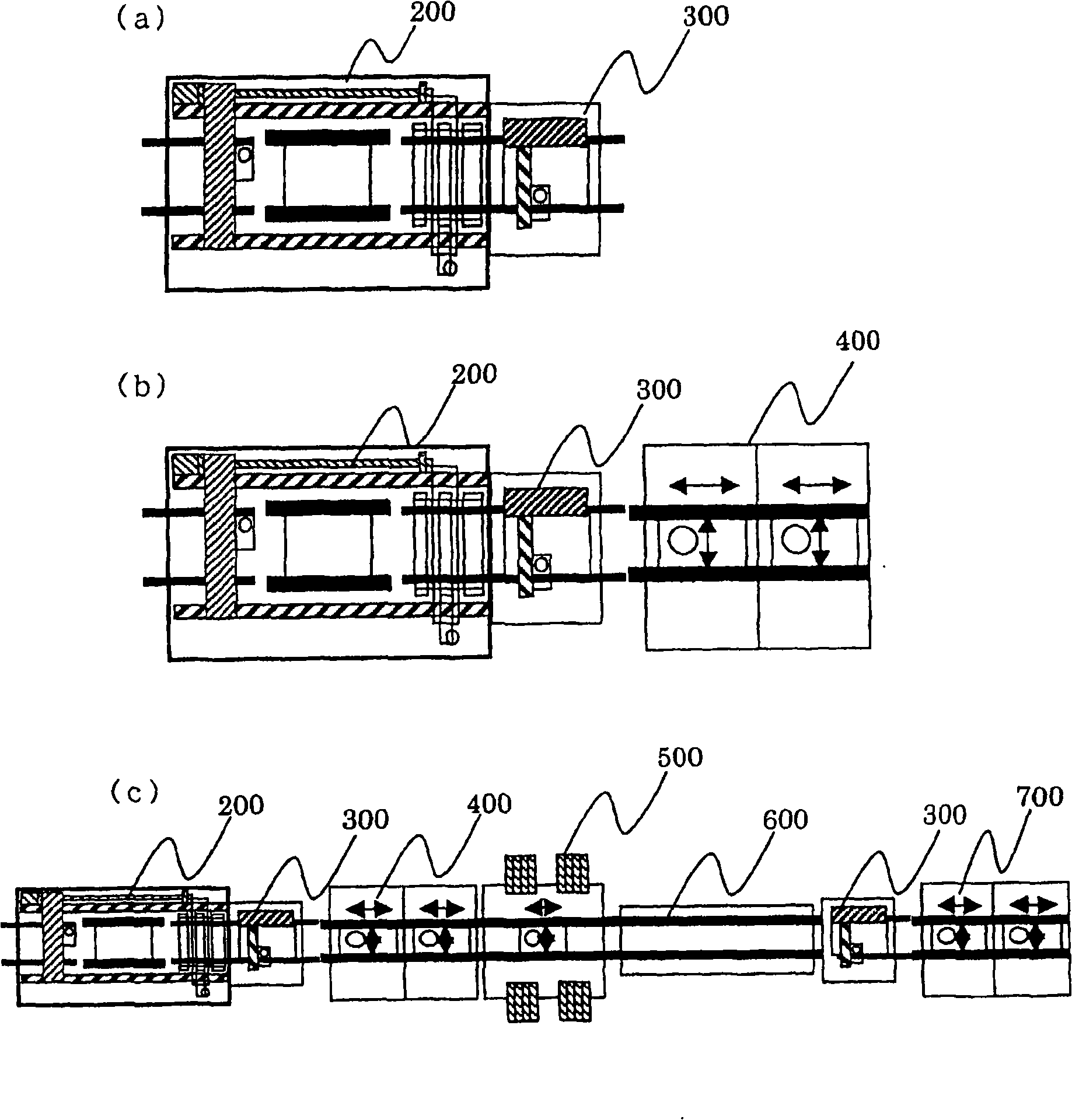

[0040] figure 1 The arrangement of each device of the solder paste printing system of the present invention is shown.

[0041] As a representative example of the printing system of the present invention, in addition to the screen printing unit 200, its configuration also includes an inspection unit 300 for inspecting the results printed on the screen printing unit (hereinafter referred to as printing unit) 200, and depending on the situation, In case the inspection unit 300 detects a poorly printed but repairable printing state, a plurality of dispenser units 400 are used to repair it.

[0042] Conventionally, in the case of applying solder paste, the solder paste to be applied is supplied to the mask surface in the printing unit 200, and after the preparation is completed, after the position of the mark is pointed and recognized, automatic operation is started, and printing After soldering the paste, the substrate is transferred to the downstream device. In this regard, as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com