Thread filter

A filter and thread technology, which is applied in the field of thread filters, can solve the problems of inconvenient cleaning and complex structure, and achieve the effects of convenient disassembly, easy cleaning and high reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

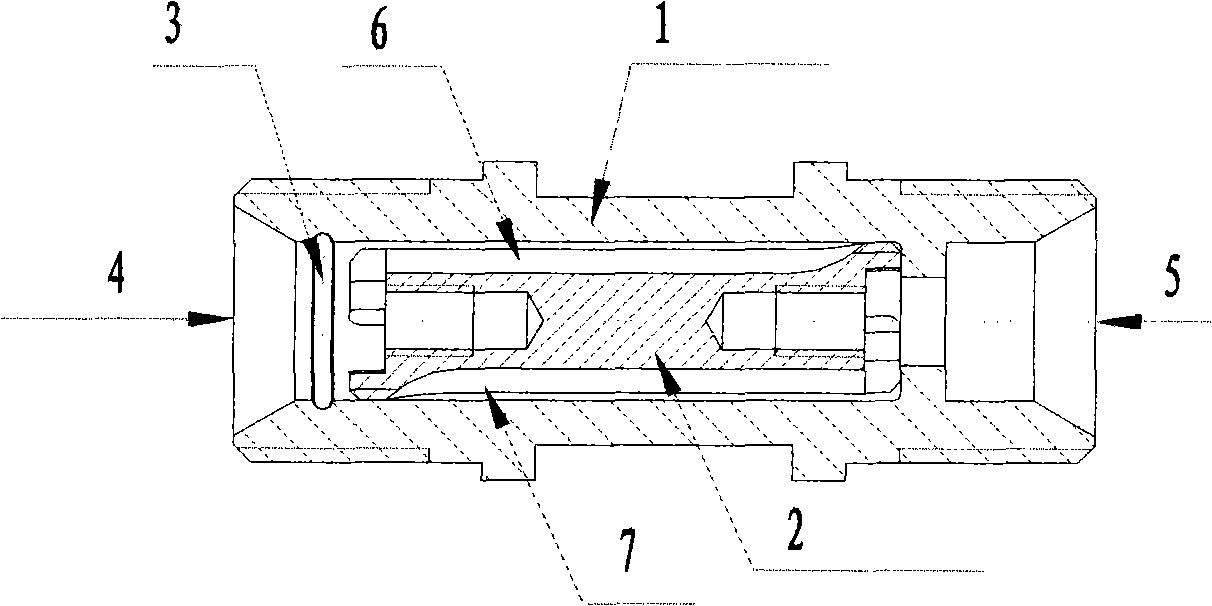

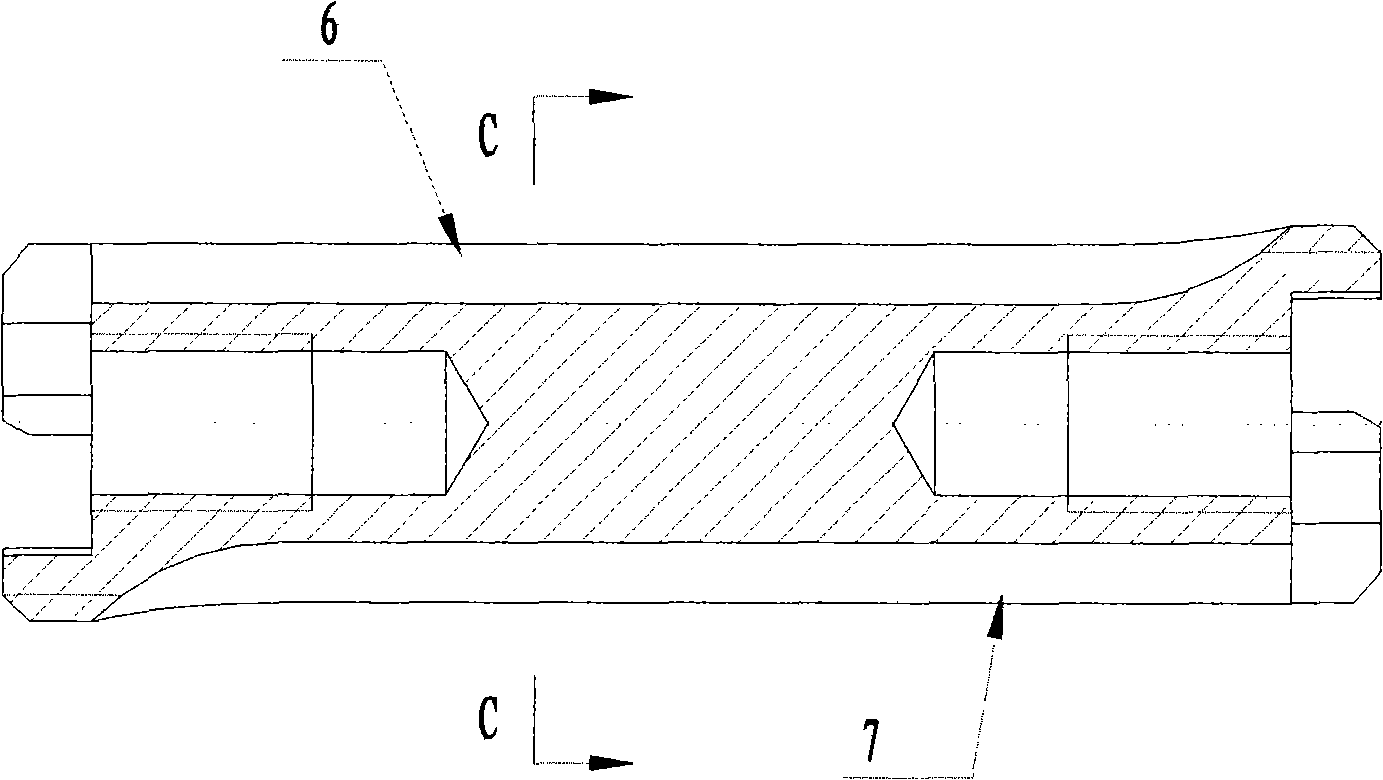

[0022] A threaded filter. The threaded filter in this embodiment includes a filter housing 1, a threaded filter element 2, a collar 3, a liquid inlet 4, and a liquid outlet 5; the threaded filter element 2 includes a liquid passage 6, a liquid B Channel 7, filter thread 8; wherein the threaded filter element 2 is loaded into the filter housing 1, one side of the housing is loaded with a collar 3, and the two ends of the filter housing 1 are respectively connected with the liquid inlet 4 and the liquid outlet 5.

[0023] In the threaded filter of this embodiment, the filter housing 1 adopts a cylindrical structure; the connection structure between the filter housing 1 and the external pipeline is a tapered sealing structure connected by threads.

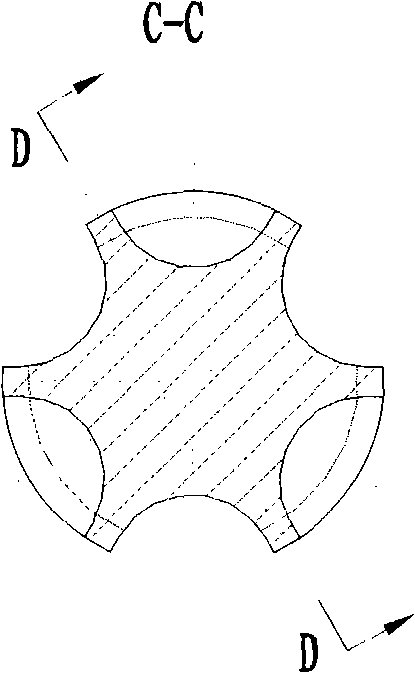

[0024] In this embodiment, the threaded filter has three A liquid passages 6 and B liquid passages 7 .

[0025] In the threaded filter of this embodiment, the diameter range of the outer cylinder of the threaded filter element 2 is 9m...

Embodiment 2

[0028] A threaded filter. The threaded filter in this embodiment includes a filter housing 1, a threaded filter element 2, a collar 3, a liquid inlet 4, and a liquid outlet 5; the threaded filter element 2 includes a liquid passage 6, a liquid B Channel 7, filter thread 8; wherein the threaded filter element 2 is loaded into the filter housing 1, one side of the housing is loaded with a collar 3, and the two ends of the filter housing 1 are respectively connected with the liquid inlet 4 and the liquid outlet 5.

[0029] In the threaded filter of this embodiment, the filter housing 1 adopts a cylindrical structure; the connection structure between the filter housing 1 and the external pipeline is a tapered sealing structure connected by threads.

[0030] In the threaded filter of this embodiment, the number of A liquid channels 6 is 6, and the number of B liquid channels 7 is 3.

[0031] In the threaded filter of this embodiment, the diameter range of the outer cylinder of the ...

Embodiment 3

[0034] A threaded filter. The threaded filter in this embodiment includes a filter housing 1, a threaded filter element 2, a collar 3, a liquid inlet 4, and a liquid outlet 5; the threaded filter element 2 includes a liquid passage 6, a liquid B Channel 7, filter thread 8; wherein the threaded filter element 2 is loaded into the filter housing 1, one side of the housing is loaded with a collar 3, and the two ends of the filter housing 1 are respectively connected with the liquid inlet 4 and the liquid outlet 5.

[0035] In this embodiment of the threaded filter, the filter housing 1 adopts a rectangular structure; the connection structure between the filter housing 1 and the external pipeline is a bolt-connected end face sealing structure.

[0036] In the threaded filter of this embodiment, the number of A liquid channels 6 is 10, and the number of B liquid channels 7 is 10.

[0037] In the threaded filter of this embodiment, the diameter range of the outer cylinder of the thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com