Electronic product with metal connecting structure and method for producing the same

A technology for electronic products and metal connections, applied in welding/welding connections, conductive adhesive connections, electrical equipment casings/cabinets/drawers, etc., can solve metal casing deformation, discoloration, locking components or clamping structure synchronous completion, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

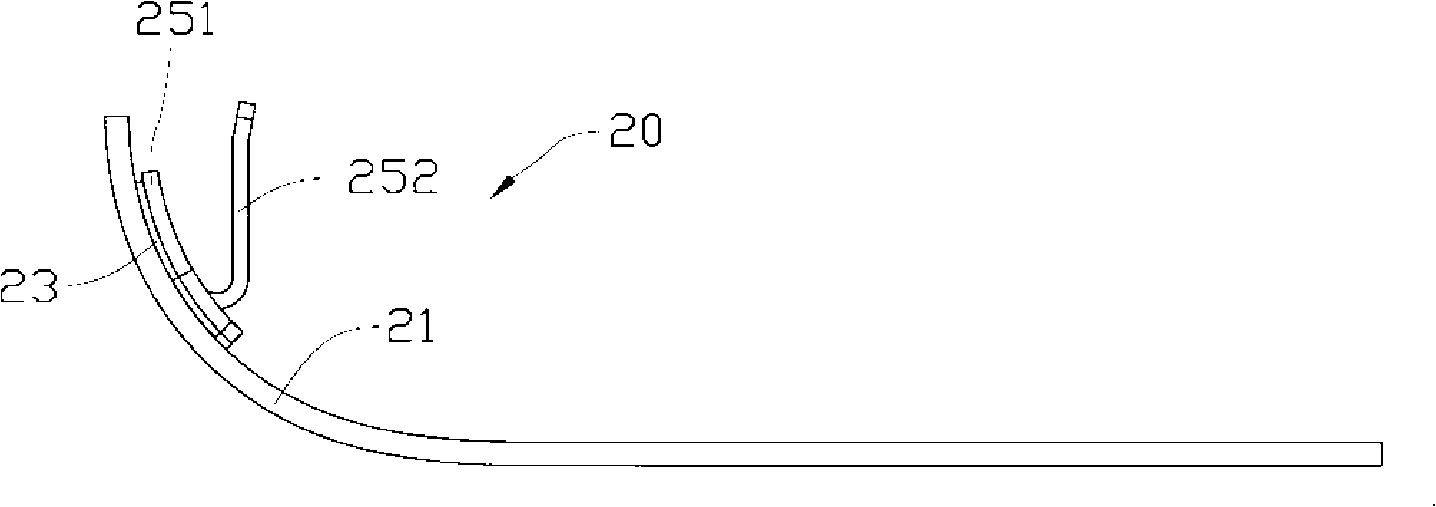

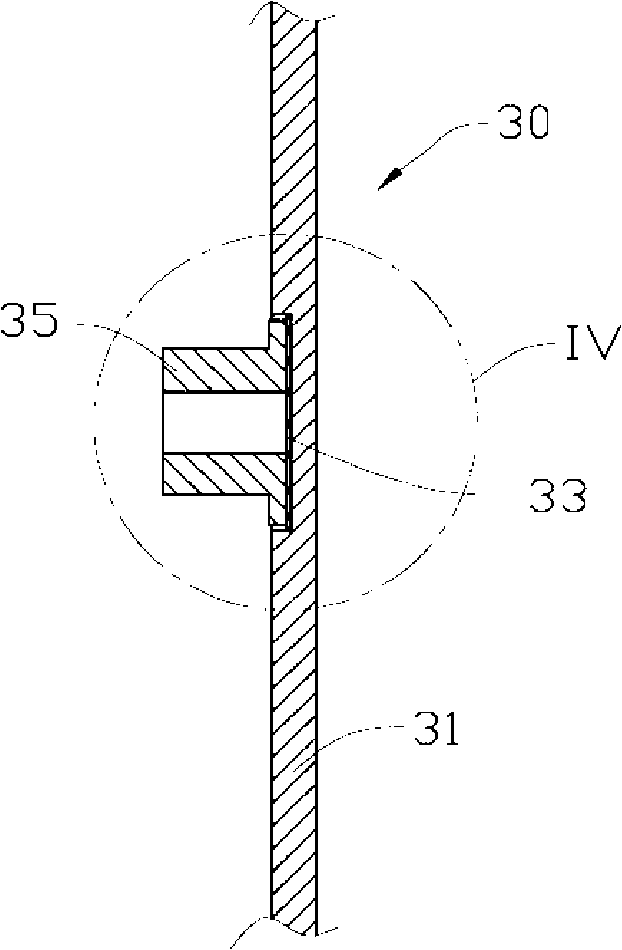

[0014] Please also see figure 1 and figure 2 , The electronic product according to the preferred embodiment 1 of the present invention includes a metal connecting structure 20 , which includes a metal shell 21 , a hot melt adhesive layer 23 and an elastic piece 25 . The elastic piece 25 is fixed inside the metal shell 21 through the hot melt adhesive layer 23 .

[0015] In this embodiment, the metal connection structure 20 is applied to mp3 electronic products. The metal shell 21 is a curved shell. The elastic piece 25 is formed by stamping, and includes a rectangular base 251 and a U-shaped elastic portion 252 . Two legs of the U-shaped elastic portion 252 extend outward from one end of the base portion 251 . The shape of the hot-melt adhesive layer 23 matches the shape of the base portion 251 of the elastic piece 25 , so that the hot-melt adhesive layer 23 is in full contact with the base portion 251 . The hot melt adhesive layer 23 is a solvent-free adhesive, which ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com