Optical fiber connector

A technology of optical fiber splices and optical fibers, which is applied in the coupling of optical waveguides, etc., can solve the problems of difficult installation, many tools used, and complicated operation, and achieve the effects of low manufacturing cost, strong bonding, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in detail below in conjunction with the accompanying drawings.

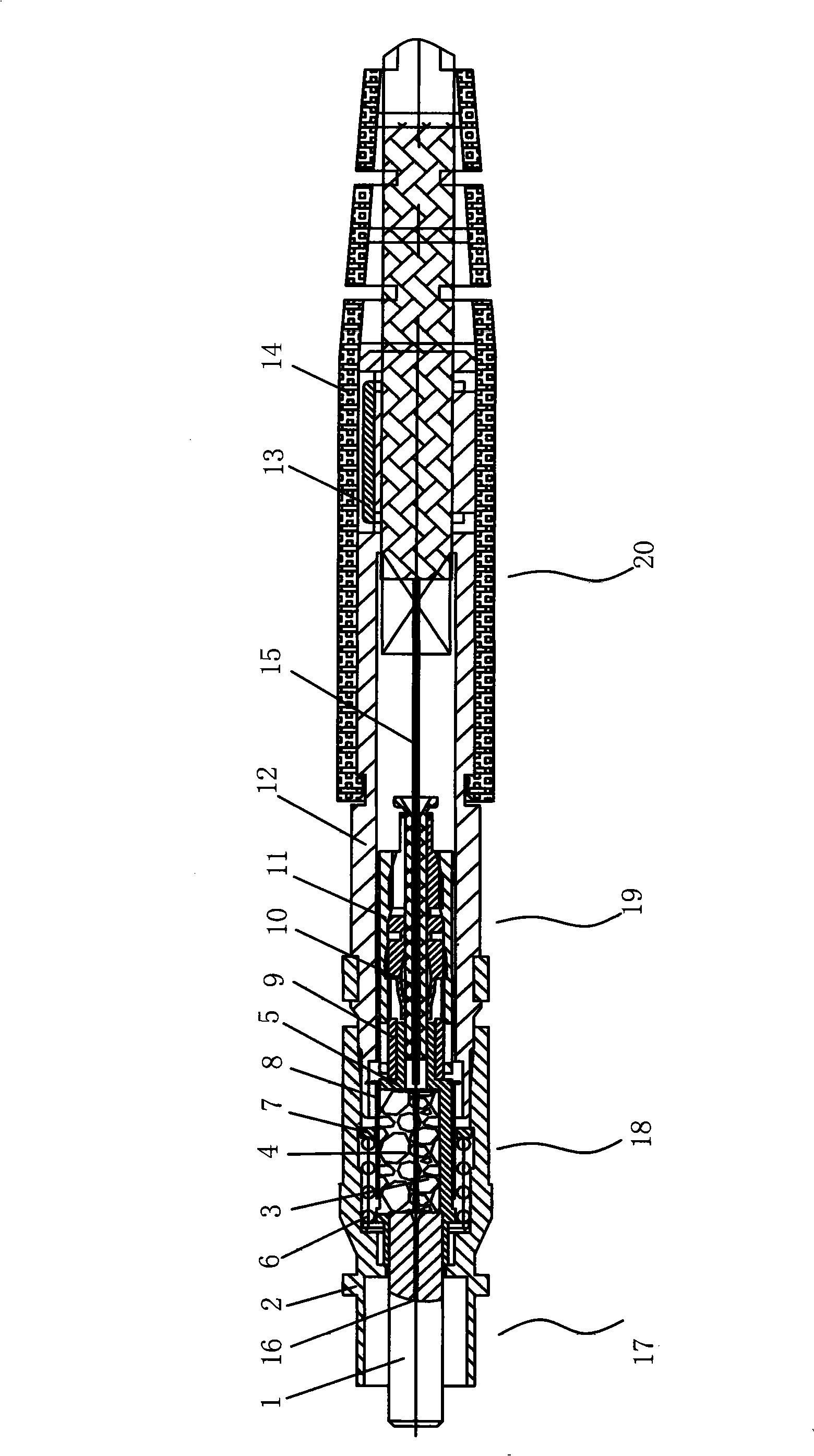

[0062] Such as figure 1 , 2 As shown, the optical fiber splice of the present invention includes a housing, and a guiding device 17 for guiding and positioning when the optical fiber is inserted, and a pressing device for compressing the bare fiber when the optical fiber is inserted in place are arranged in the housing. Tightening device 18 and locking device 19 for pushing and compressing the optical fiber; the tail of the housing is provided with the fastening device 20 for strongly clamping the outer skin of the optical fiber.

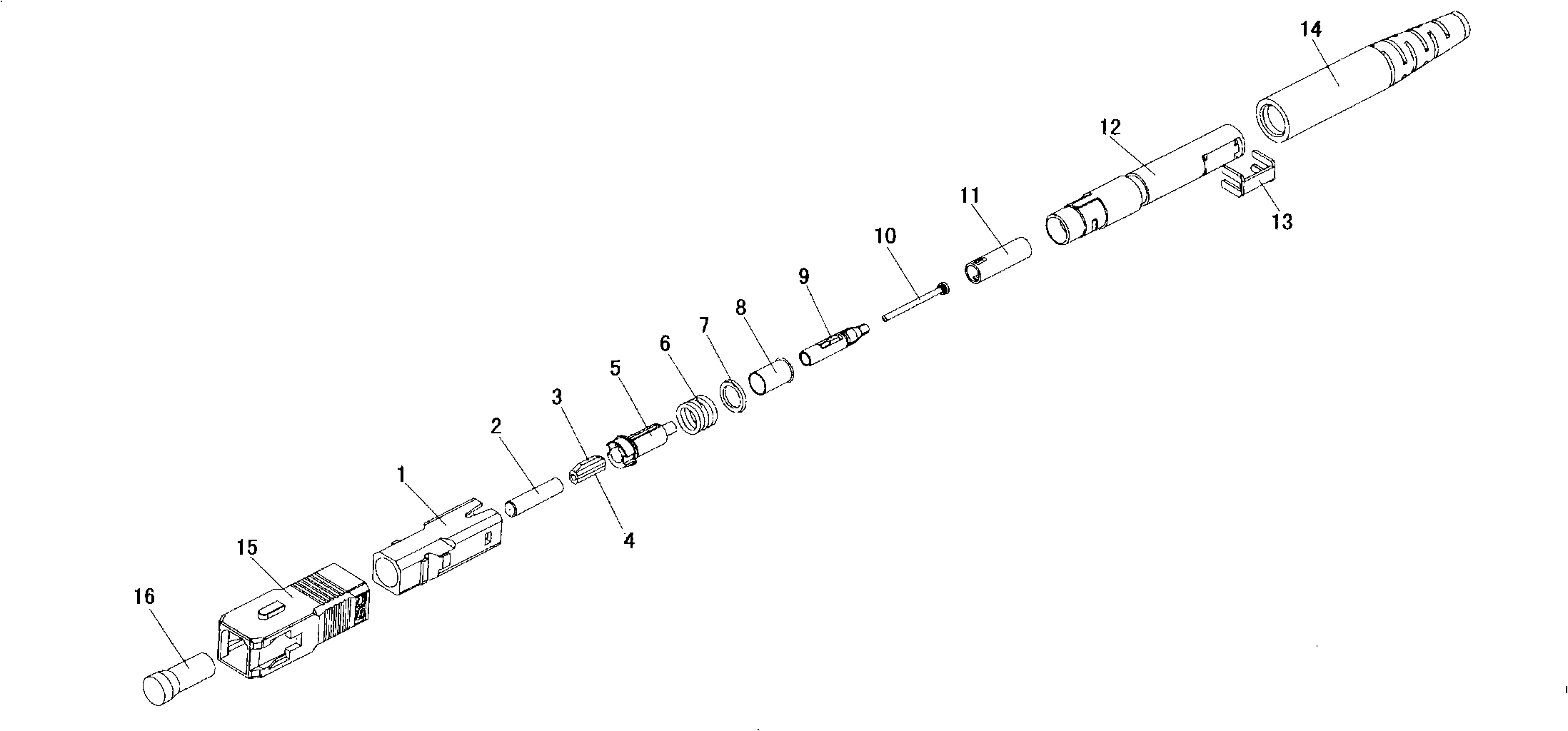

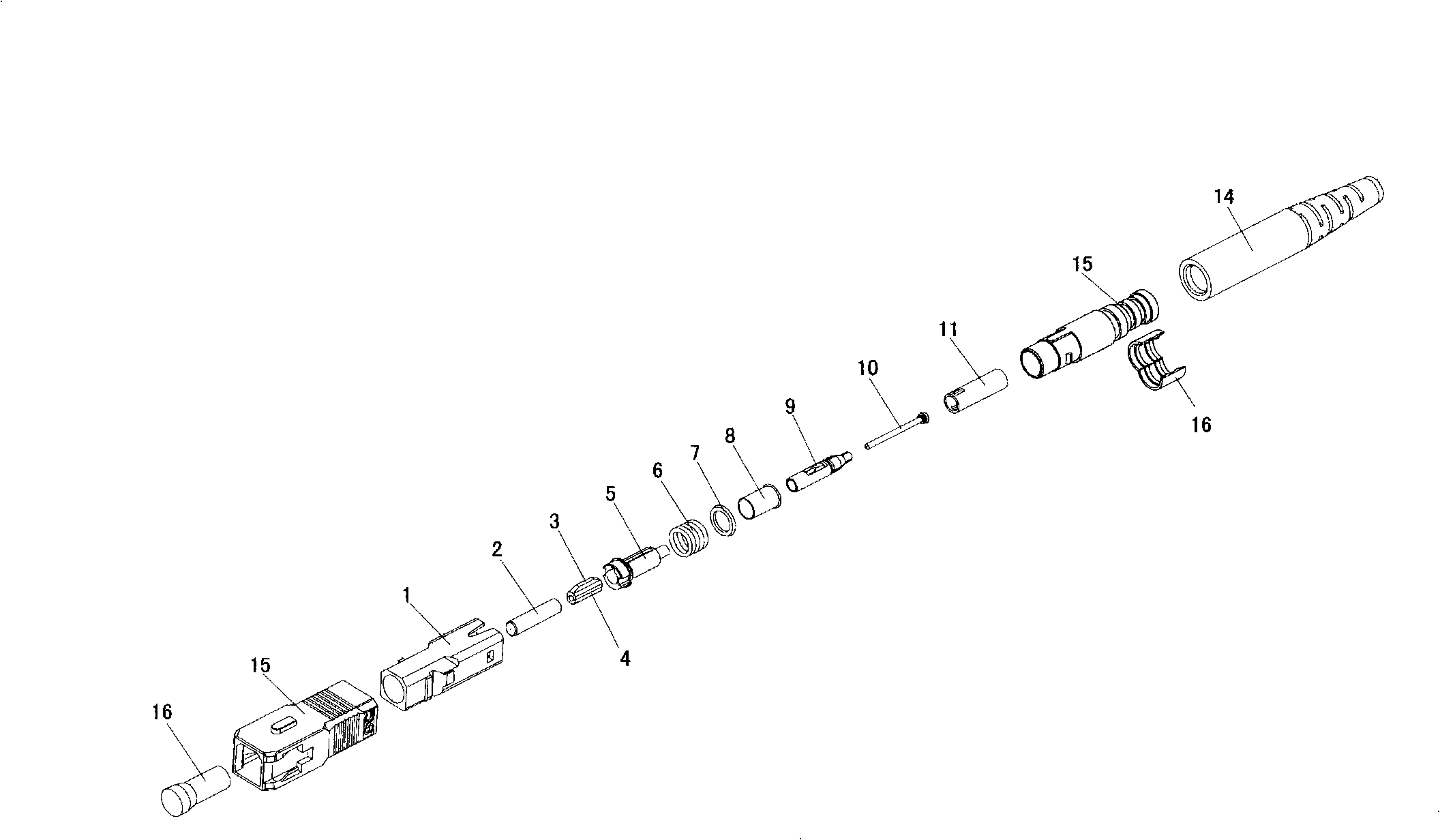

[0063] Such as Figure 5 , 8 and 9, the guide device 17 includes: the socket socket sleeve 5 and the pin 2. The pin holder sleeve 5 includes a through hole 5-1 for the front end to be mated with the pin 2 and a housing cavity 5-2 in the middle for accommodating the pressure block 3 and the gland 4. The pin 2 is crimped on the pin In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com