Large mode field optical fiber transmission system

A technology of optical fiber transmission and large mode field, which is applied in cladding optical fiber, bundled optical fiber, optical waveguide and optical guide, etc. It can solve the problems of unresolved optical fiber bending loss, inability to guarantee high-order modes, unfavorable manufacturing, etc., and achieve low connection loss and easy Fabrication, the effect of low bending loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

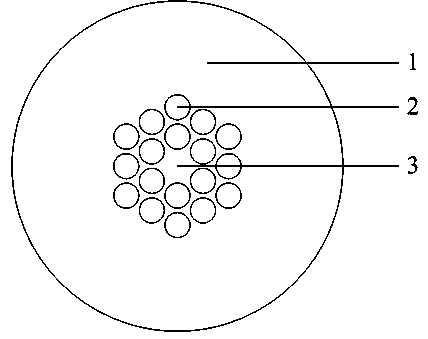

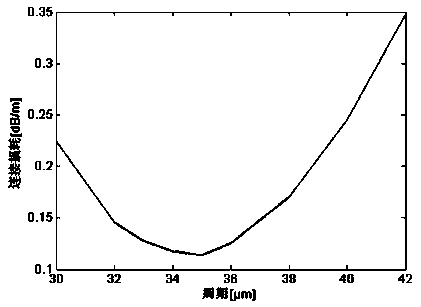

[0032] The cross-sectional structure of the main fiber is as figure 1 shown. The matrix material is pure silica, and the holes in the first auxiliary optical fiber, the second auxiliary optical fiber and the main optical fiber are filled with a solid material whose refractive index is lower than that of the matrix material. The length of the first auxiliary optical fiber at the input end is 10 mm, and the length of the second auxiliary optical fiber at the output end is 10 mm. The hole period Λ of the hole in the first auxiliary fiber 1 =38μm, hole diameter d 1 =15.2μm, the refractive index of the hole is 0.006 lower than that of the matrix material. The hole period in the main fiber is Λ=50μm, the hole diameter d=42.5μm, and the refractive index of the hole is 0.006 lower than that of the matrix material. The hole period Λ in the second auxiliary fiber 2 =33μm, hole diameter d 2 =13.2μm, the refractive index of the hole is 0.006 lower than that of the matrix material. ...

Embodiment 2

[0034] The cross-sectional structure of the main fiber is as figure 1 shown. The matrix material is pure silica, and the holes in the first auxiliary optical fiber, the second auxiliary optical fiber and the main optical fiber are filled with a solid material whose refractive index is lower than that of the matrix material. The length of the first auxiliary optical fiber at the input end is 10 mm, and the length of the second auxiliary optical fiber at the output end is 10 mm. Hole period Λ in the first auxiliary fiber 1 =54μm, hole diameter d 1 =21.6μm, the refractive index of the hole is 0.006 lower than that of the matrix material. The hole period in the main fiber is Λ=70μm, the hole diameter d=63μm, and the refractive index of the hole is 0.006 lower than that of the matrix material. Hole period Λ in the second auxiliary fiber 2 =45μm, hole diameter d 2 =18μm, the refractive index of the hole is 0.006 lower than that of the matrix material. The matrix material of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com