High-efficiency heat exchange tube for heat exchanger in ammonia/carbon dioxide cascade refrigeration system

A carbon dioxide and cascade refrigeration technology, which is applied in the direction of tubular elements, heat exchange equipment, lighting and heating equipment, etc., can solve the problem that the ammonia/carbon dioxide cascade refrigeration system is not well applied, the heat exchange efficiency of the heat exchanger is low, Increase the volume of equipment and other issues to achieve the effect of strengthening condensation heat transfer, optimizing heat transfer efficiency, and solving the effect of bulky equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

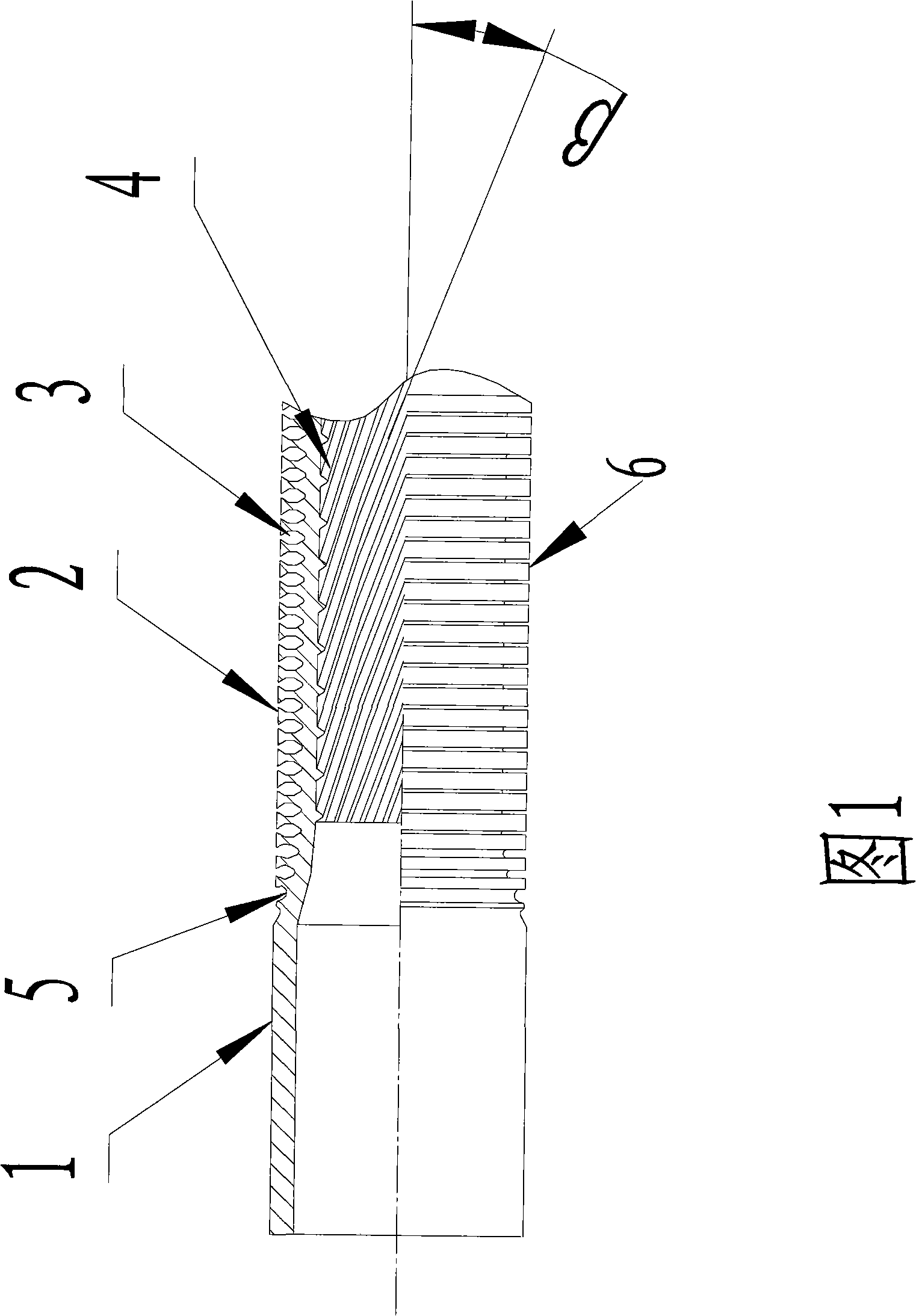

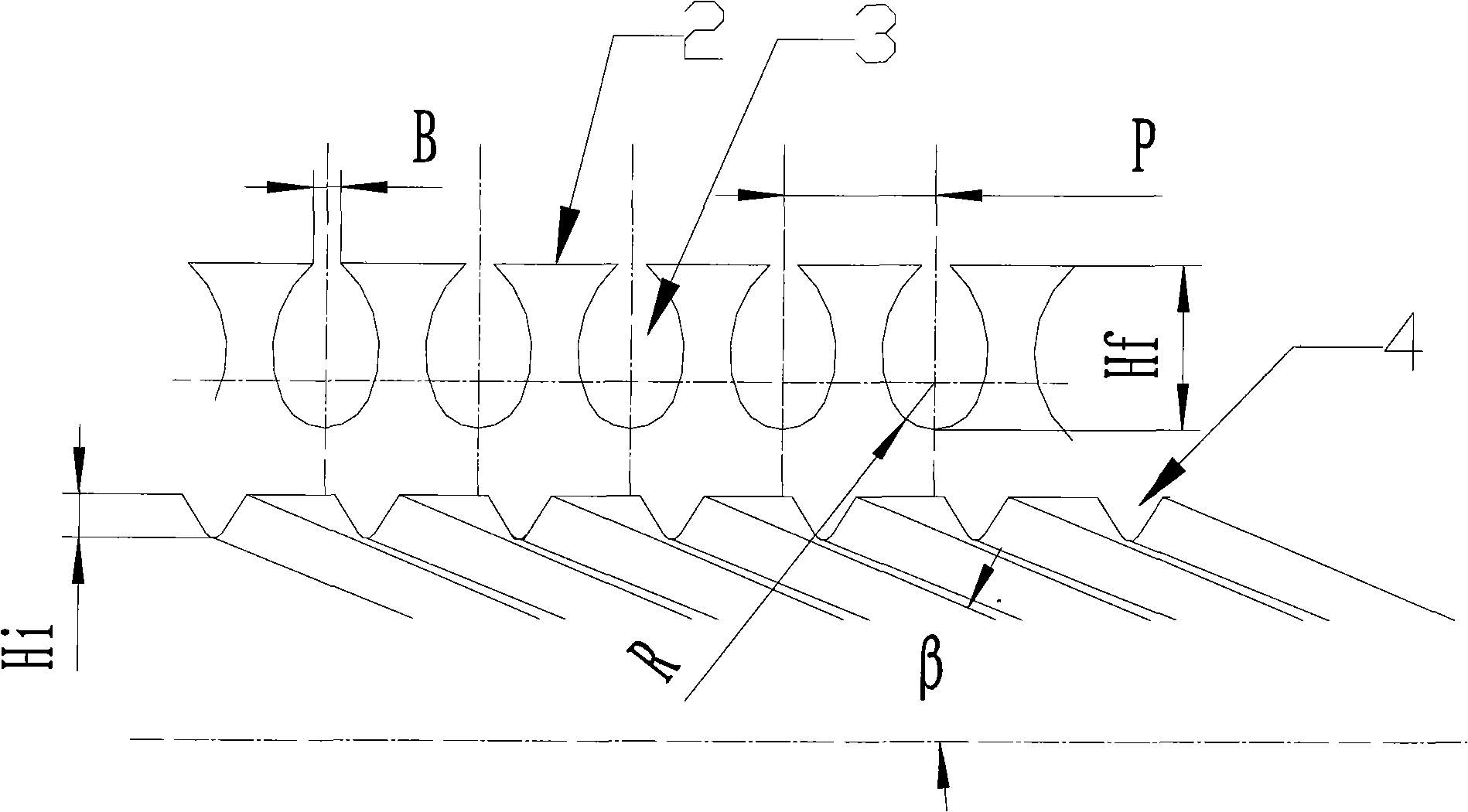

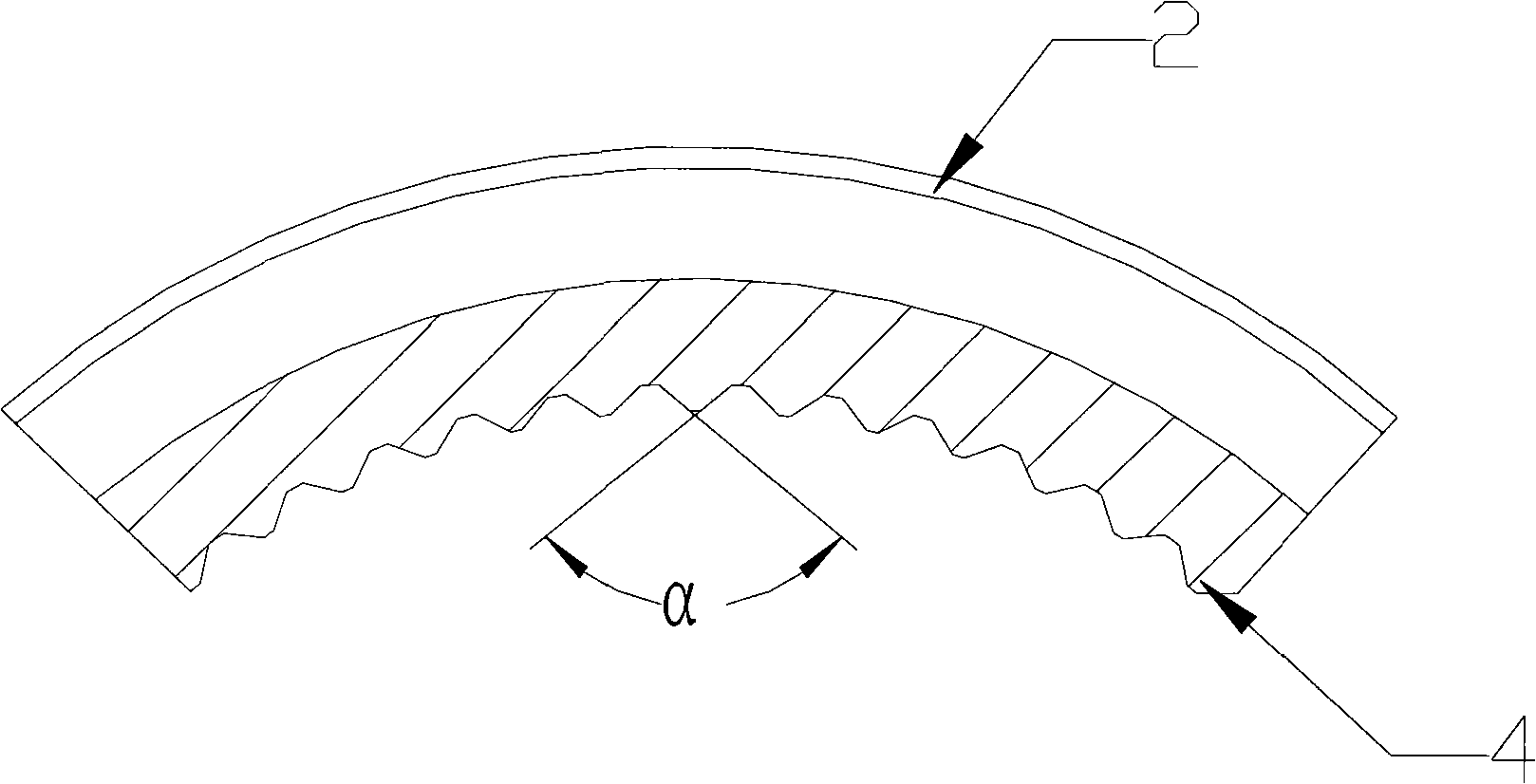

[0021] Embodiment: a high-efficiency heat exchange tube for a heat exchanger in an ammonia / carbon dioxide cascade refrigeration system (see Fig. 1- image 3 ), which is a tubular body with an inner cavity, made of steel material. The tube body is composed of a smooth tube part 1, a finned tube part 6 and a transition part 5 connecting the smooth tube 1 and the finned tube part 6, and the outer wall of the tube part 6 is provided with spirally distributed fins along the axial direction. 2. The top of each group of spiral fins extends to both sides from the bottom, in a T-shape, the pitch of the fins is P, and P is 1.0-1.8mm. The height of the T-shaped fins is Hf, and Hf is 1-1.8mm. A channel 3 is formed between the fins. The shape of the channel 3 is duck-egg-shaped. The radius of the bottom of the channel 3 is R, and the range of R is 0.15-0.6mm, which maximizes the contact angle of the bubbles and strengthens the growth and detachment of the bubbles. The top of the adjacent f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com