Process for preparing D-glucosamine hydrochlorate

A technology of glucosamine hydrochloride and a production method, which is applied to amino sugars, sugar derivatives, sugar derivatives, etc., can solve the problems of poor effect, large amount of acetic acid in hydrochloric acid, and low concentration of recycled hydrochloric acid, etc. The effect of pollution, reducing waste liquid discharge and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

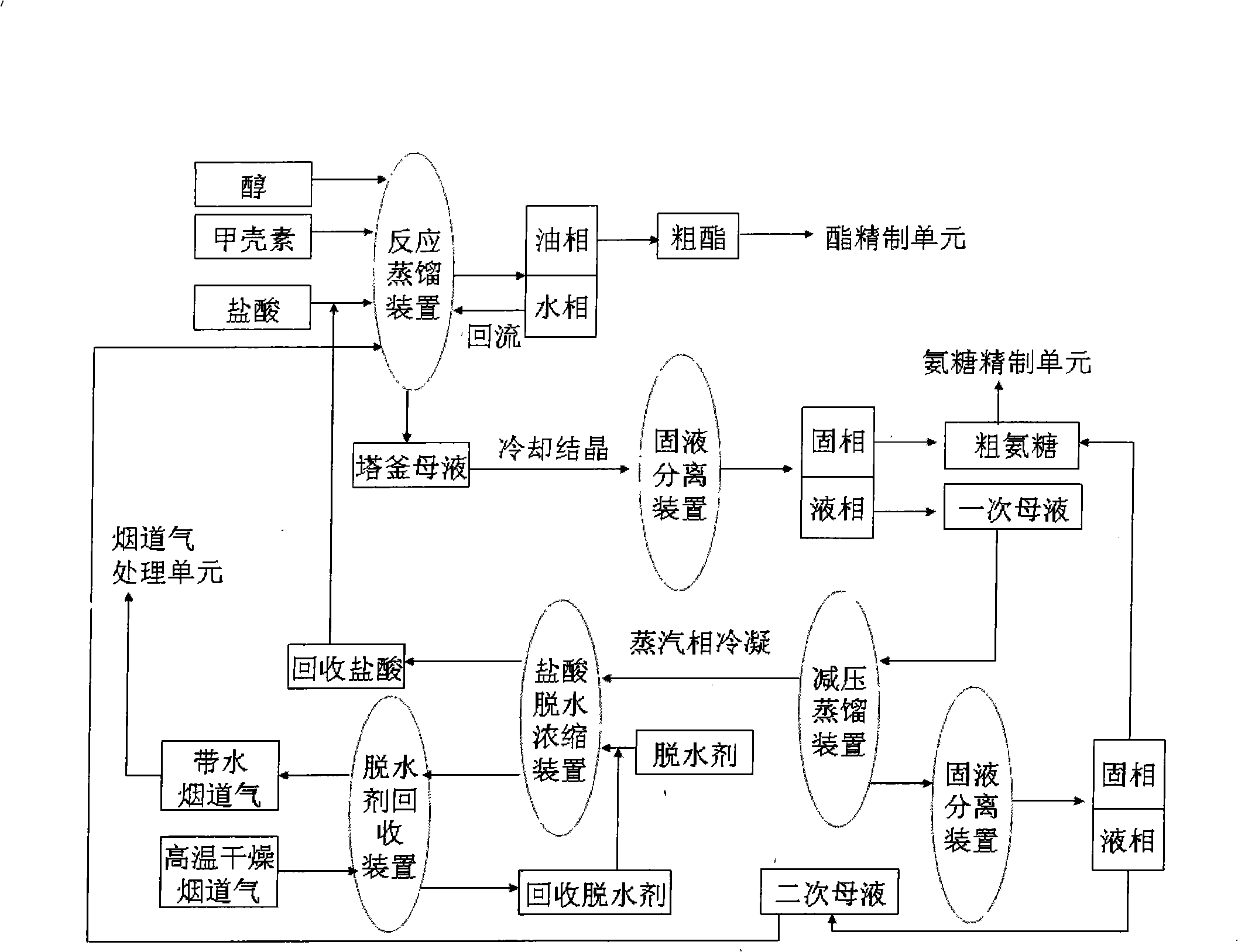

[0017] The production method of D-glucosamine hydrochloride comprises the steps: (see figure 1 )

[0018] (1) Add 240g chitin, 626g 37% hydrochloric acid and 200g ethanol in the reaction distillation device, the temperature is controlled at 50°C, after the addition is complete, the controlled temperature is 95°C for reaction, the top obtains distillate (ester and water etc. form a co- Boilers go up to the top of the distillation tower, and condense on the top of the tower, and are divided into two phases, the water phase refluxes and re-enters the reaction distillation device, while the oil phase is crude ester, which can be refined to obtain ethyl acetate) and the bottom to obtain the residual liquid ;

[0019] (2) filtering the residual liquid to remove slag, cooling the filtrate to precipitate solids, and separating the solid and liquid to obtain crude D-glucosamine hydrochloride and primary mother liquor;

[0020] (3) Dissolve the crude glucosamine in hot water at a mass...

Embodiment 2

[0025] The production method of D-glucosamine hydrochloride comprises the steps:

[0026] (1) Add chitin, sulfuric acid (mass fraction: 70%) and methanol into the reaction distillation device, heat up to 85° C., carry out the reaction, obtain the distillate at the top and obtain the residual liquid at the bottom;

[0027] (2) filtering the residual liquid to remove slag, cooling the filtrate to precipitate solids, and separating the solid and liquid to obtain crude D-glucosamine hydrochloride and primary mother liquor;

[0028] (3) Dissolve the crude D-glucosamine hydrochloride in hot water at a mass ratio of 1:1, add 2% activated carbon of the mass of the crude D-glucosamine hydrochloride, reflux for 20 minutes, and filter while hot, The filtrate was evaporated at 70°C to precipitate a solid. Dissolve the solid in ethanol, control the mass ratio of ethanol to the precipitated solid to be 3:1, stir, cool and stand still, crystals precipitated during the cooling process, filter...

Embodiment 3

[0031] The production method of D-glucosamine hydrochloride comprises the steps:

[0032] (1) Add chitin, 37% hydrochloric acid and propanol to the reaction distillation device, heat up to 110° C., carry out the reaction, obtain the distillate at the top and obtain the residual liquid at the bottom;

[0033] (2) filtering the residual liquid to remove slag, cooling the filtrate to precipitate solids, and separating the solid and liquid to obtain crude D-glucosamine hydrochloride and primary mother liquor;

[0034] (3) Dissolve the crude D-glucosamine hydrochloride in hot water at a mass ratio of 1:4, add 5% activated carbon of the mass of the crude D-glucosamine hydrochloride, reflux for 100 minutes, and filter while hot, The filtrate was evaporated at 80°C to precipitate a solid. Dissolve the solid in ethanol, control the mass ratio of ethanol to the precipitated solid to be 5:1, stir, cool and stand still, and crystals precipitated during the cooling process, filtered and wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com