Process for synthesizing YAG single crystal nano-powder

A technology of single crystal nanometer and powder, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc. It can solve the problems of difficulty in controlling the shape of powder particles, complicated flow system equipment, and inability to obtain powder materials. Achieve the effect of low cost, easy access to raw materials, and promotion of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

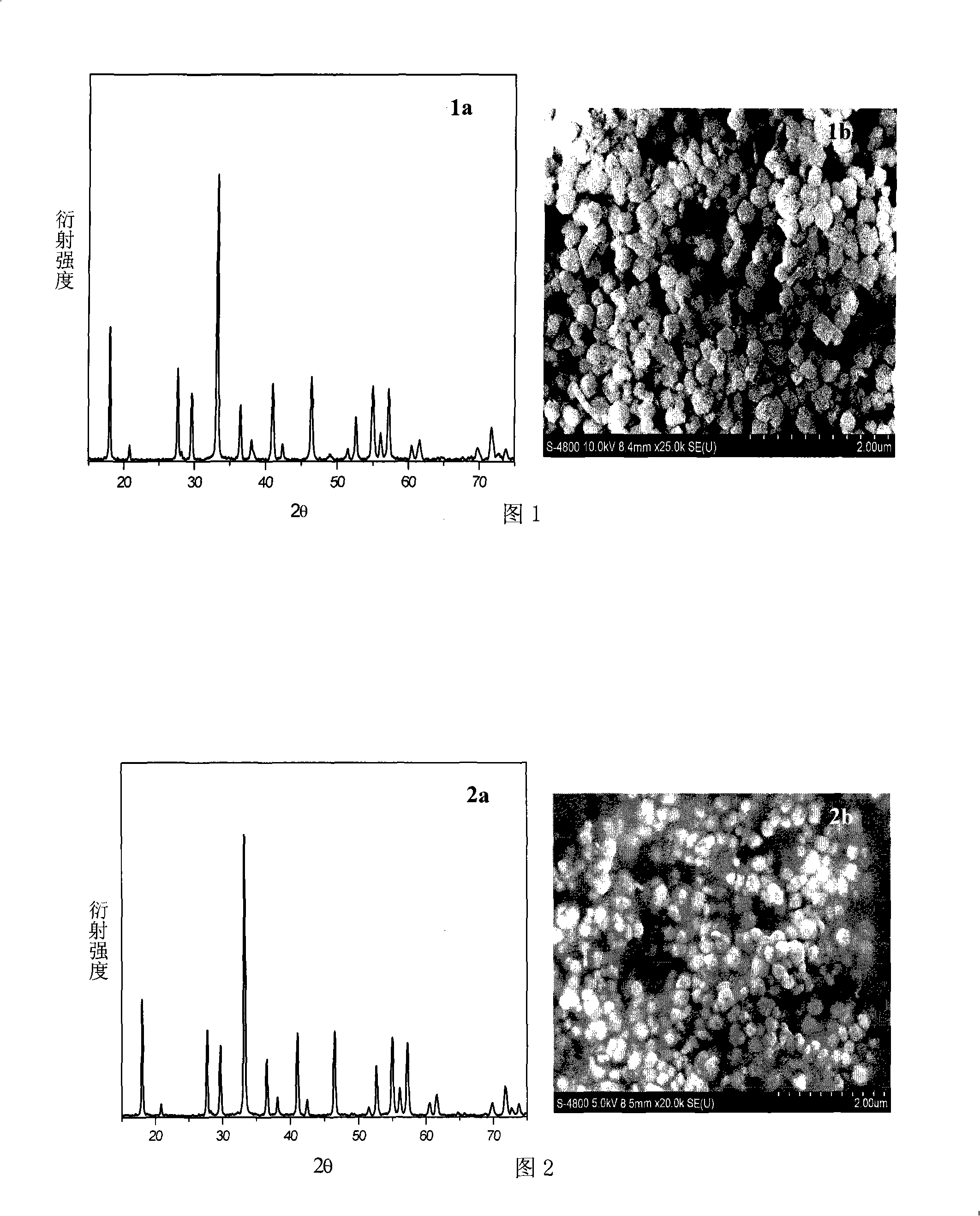

Image

Examples

Embodiment 1

[0035] 1. Ingredients:

[0036] 1) 12 milliliters of 0.5 mol / liter yttrium nitrate Y (NO 3 ) 3 solution, 20 ml of 0.5 mol / L aluminum nitrate Al(NO 3 ) 3 The solution, followed by 68 ml of deionized water, were added to a 250 ml beaker (beaker 1).

[0037] 2) 150 ml of 1 mol / L ammonium bicarbonate NH 4 HCO 3 The solution was added to a 500 ml beaker (beaker 2).

[0038] 2. Co-precipitation:

[0039] The solution in beaker 1 was added dropwise to beaker 2, and stirred continuously with a glass rod, reacted at 25°C and aged for 60 minutes to obtain a solid-liquid mixture with precipitation.

[0040] 3. Washing and filtering:

[0041] The solid-liquid mixture with the precipitate was filtered through a vacuum filter (the pore size of the filter membrane was 0.2 μm) to obtain the precipitate. The precipitate was redispersed in deionized water, and filtered with a vacuum filter (the pore size of the filter membrane was 0.2 μm). The above steps were repeated 3 times to obta...

Embodiment 2

[0054] 1. Ingredients:

[0055] 1) 11.76 milliliters of 0.5 mol / liter yttrium nitrate Y (NO 3 ) 3 solution, 20 ml of 0.5 mol / L aluminum nitrate Al(NO 3 ) 3 solution, 1.2 ml of 0.1 mol / L neodymium nitrate Nd(NO 3 ) 3 The solution, 67.04 ml of deionized water were added sequentially to a 250 ml beaker (beaker 1).

[0056] 2) 150 ml of 1 mol / L ammonium bicarbonate NH 4 HCO 3 The solution was added to a 500 ml beaker (beaker 2).

[0057] 2. Co-precipitation:

[0058] The solution in beaker 1 was added dropwise to beaker 2, and stirred continuously with a glass rod, reacted at 23°C and aged for 90 minutes to obtain a solid-liquid mixture with precipitation.

[0059] 3. Washing and filtering:

[0060] The solid-liquid mixture with the precipitate was filtered through a vacuum filter (the pore size of the filter membrane was 0.2 μm) to obtain the precipitate. The precipitate was redispersed in deionized water, and filtered with a vacuum filter (the pore size of the filter ...

Embodiment 3

[0073] 1. Ingredients:

[0074] 1) 11.76 milliliters of 0.5 mol / liter yttrium nitrate Y (NO 3 ) 3 solution, 20 ml of 0.5 mol / L aluminum nitrate Al(NO 3 ) 3 solution, 1.2 ml of 0.1 mol / L europium nitrate Eu(NO 3 ) 3 The solution, 67.04 ml of deionized water were added sequentially to a 250 ml beaker (beaker 1).

[0075] 2) 150 ml of 1 mol / L ammonium bicarbonate NH 4 HCO 3 The solution was added to a 500 ml beaker (beaker 2).

[0076] 2. Co-precipitation:

[0077] The solution in beaker 1 was added dropwise to beaker 2, and stirred continuously with a glass rod, reacted at 20°C and aged for 120 minutes to obtain a solid-liquid mixture with precipitation.

[0078] 3. Washing and filtering:

[0079] The solid-liquid mixture with the precipitate was filtered through a vacuum filter (the pore size of the filter membrane was 0.2 μm) to obtain the precipitate. The precipitate was redispersed in deionized water, and filtered with a vacuum filter (the pore size of the filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com