Synthetic method for one-dimensional single crystal bismuth oxide nano material

A technology of nanomaterials and synthesis methods, which is applied in the field of liquid-phase synthesis of one-dimensional single-crystal bismuth oxide nanomaterials, can solve the problems of increased preparation costs and unavailability, and achieve the effects of easy control, no pollution, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

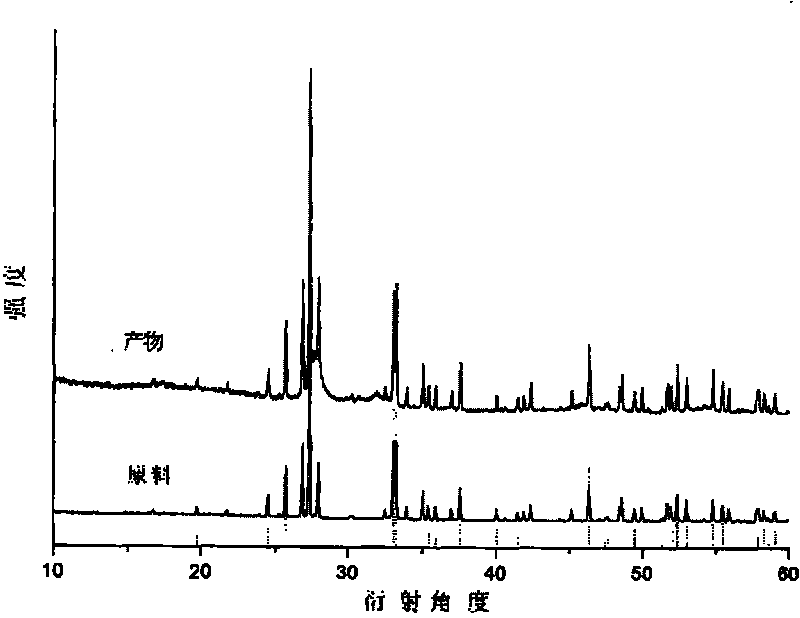

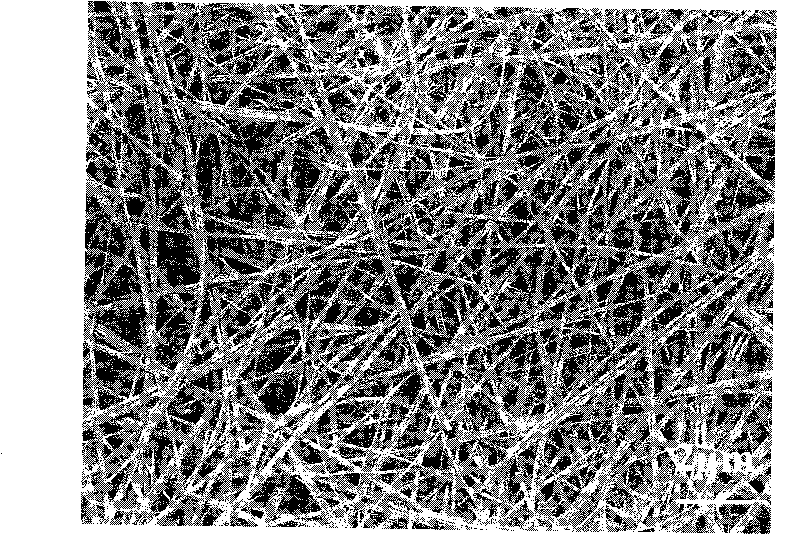

[0018] Weigh 0.1mmolα-Bi 2 o 3 Put the powder and 0.3mmol of potassium sulfate in a 23mL stainless steel pressure-resistant reactor, add 10mL of deionized water, and stir to disperse evenly. Seal the reaction kettle, react at 160°C for 24 hours, cool to room temperature, filter with funnel, and wash with deionized water to obtain a light yellow powder. The product was identified by X-ray powder diffraction as α-phase bismuth oxide having the same structure as the raw material. Scanning electron microscopy shows that the raw material is irregular micron-sized α-Bi 2 o 3 Particles, after being treated by the method described in Example 1, one-dimensional single crystal α-Bi with unique shape and relatively uniform size distribution can be obtained 2 o 3 nanomaterials( figure 2 ), and its length can reach tens of microns. In addition, the raw material α-Bi 2 o 3 The specific surface area is only 0.2m 2 g -1 , the specific surface area of the product can be increased...

Embodiment 2

[0020] Weigh 0.5mmolα-Bi 2 o 3 Put the powder and 10mmol of potassium sulfate in a 23mL stainless steel pressure-resistant reactor, add 10mL of deionized water, and stir to disperse evenly. Seal the reaction kettle, react at 200° C. for 10 h, cool to room temperature, filter with funnel, and wash with deionized water to obtain light yellow powder. The product was identified as α-phase bismuth oxide by X-ray powder diffraction. Selected area electron diffraction of a single nanomaterial proves that the product is a single crystal with a width of about 50nm.

Embodiment 3

[0022] Weigh 10mmolα-Bi 2 o 3 Put the powder and 50mmol of magnesium sulfate in a 100mL stainless steel pressure-resistant reactor, add 30mL of deionized water, and stir to make it evenly dispersed. Seal the reaction kettle, react at 180° C. for 48 h, cool to room temperature, filter with funnel, wash with deionized water, and obtain a light yellow powder. The product was identified as α-phase bismuth oxide by X-ray powder diffraction. Scanning electron microscopy showed that the product was a one-dimensional single crystal α-Bi with unique shape and relatively uniform size distribution. 2 o 3 nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com