Method for preparing lubrication deacidification agent

A technology for deacidifying agent and lubricating oil, which is applied in the field of preparation of lubricating oil base oil deacidifying agent

Inactive Publication Date: 2008-11-26

BEIJING UNIV OF CHEM TECH

View PDF1 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0011] The purpose of the present invention is to propose a preparation method of lubricating oil deacidification agent, and make it have the characteristics of high removal efficiency, simple process, low cost and high industrial application value, and solve the problem of deep deacidification of lubricating oil base oil

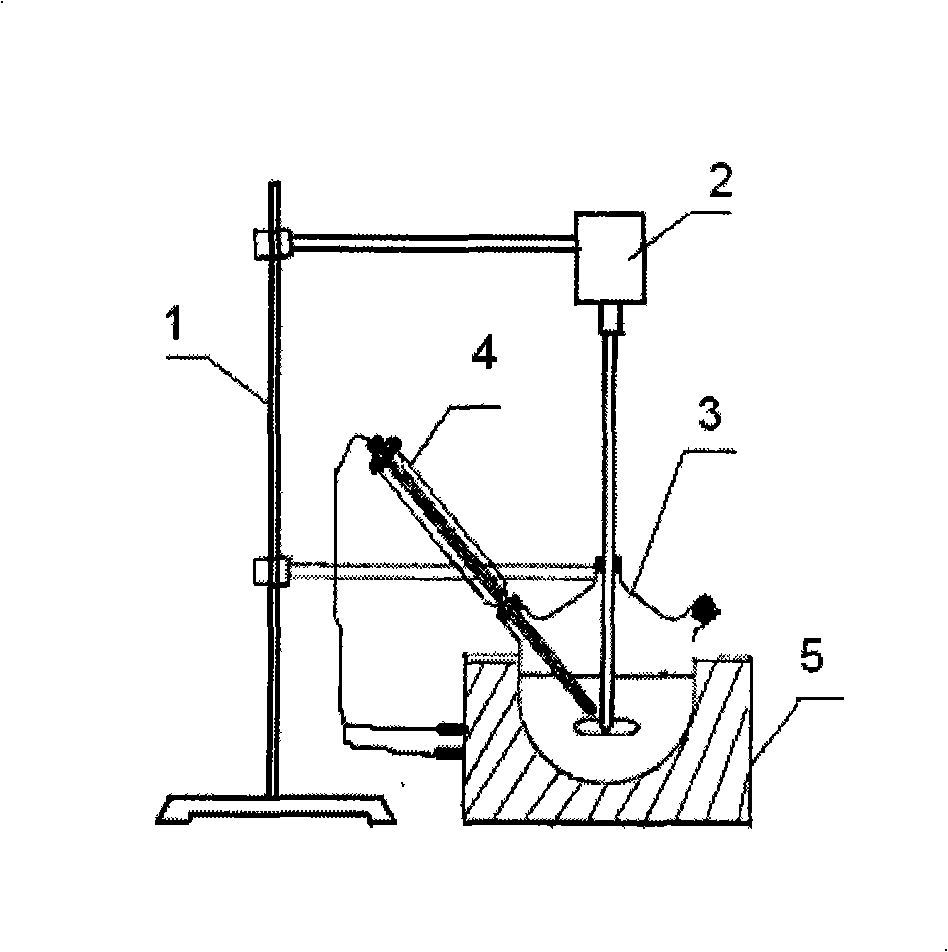

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

[0016] Example: Weighing 3gCaCl 2 Put it into a three-neck flask, add 50ml of deionized water and stir to dissolve, raise the temperature to 80°C, add 2g of activated clay under constant stirring, then add 50ml of 1.08mol / L NaOH solution dropwise, and stir at constant temperature for 4h after the addition. Filter and wash until there is no Cl in the filtrate - Exist, dry to get solid deacidification agent.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a preparation method for an acid removal agent of lubricating oil. The acid removal agent takes one or a plurality of substances of ZnCl2, MgCl2, CaCl2, and NaOH, and the like, as raw material and compounds into solution in certain concentration. Within 40 to 95 DEG C, the solution is mixed with one or a plurality of activated clay, bentonite and diatomite, and the like, and then added into NaOH solution in certain quantity and concentration. After a period of reaction under the condition of heat prevention, the mixture is filtered, washed and dried to obtain a solid acid removal agent. The solid acid removal agent can react with acid components in the base oil of the lubricating oil so that the acid components are absorbed on the acid removal agent to effectively decrease the acid value of the base oil of the lubricating oil. When in use, the lubricating oil is heated to the temperature of 40 DEG C to 250 DEG C and the acid removal agent is fully mixed with the lubricating oil by 0.1 percent to 5 percent (the mass fraction of the acid removal agent). At the set temperature, the acid removal agent reacts with the acid components in the lubricating oil, which is absorbed on the acid removal agent; meanwhile, the acid value of the lubricating oil can decrease below 0.01mgKOH / g.

Description

technical field [0001] The invention relates to a preparation technology of a lubricating oil base oil deacidification agent, and mainly relates to a preparation method of a solid alkali deacidification agent and a process condition for deep deacidification of a lubricating oil base oil. Background technique [0002] In addition to certain viscosity, good viscosity-temperature performance, anti-oxidation stability, low carbon residue and good chroma, lubricating oil also has certain requirements for acid value. Generally, the acid value of lubricating oil should not exceed 0.03mgKOH / g. The acid value of lubricating oil is mainly caused by naphthenic acid, which will corrode equipment and mechanical parts during storage, transportation and use, reduce the performance of lubricating oil, and reduce the quality of lubricating oil. Therefore, it is of great significance to remove the acidic substances in the lubricating base oil and reduce the acid value of the base oil. [0...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10G19/073

Inventor 李保山于伟

Owner BEIJING UNIV OF CHEM TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com