Experiment test panel for plasma display

A plasma and display technology, applied in the field of experimental test screen for plasma display, can solve the problems of long production cycle and low test efficiency, and achieve the effects of improving test efficiency, shortening development cycle and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

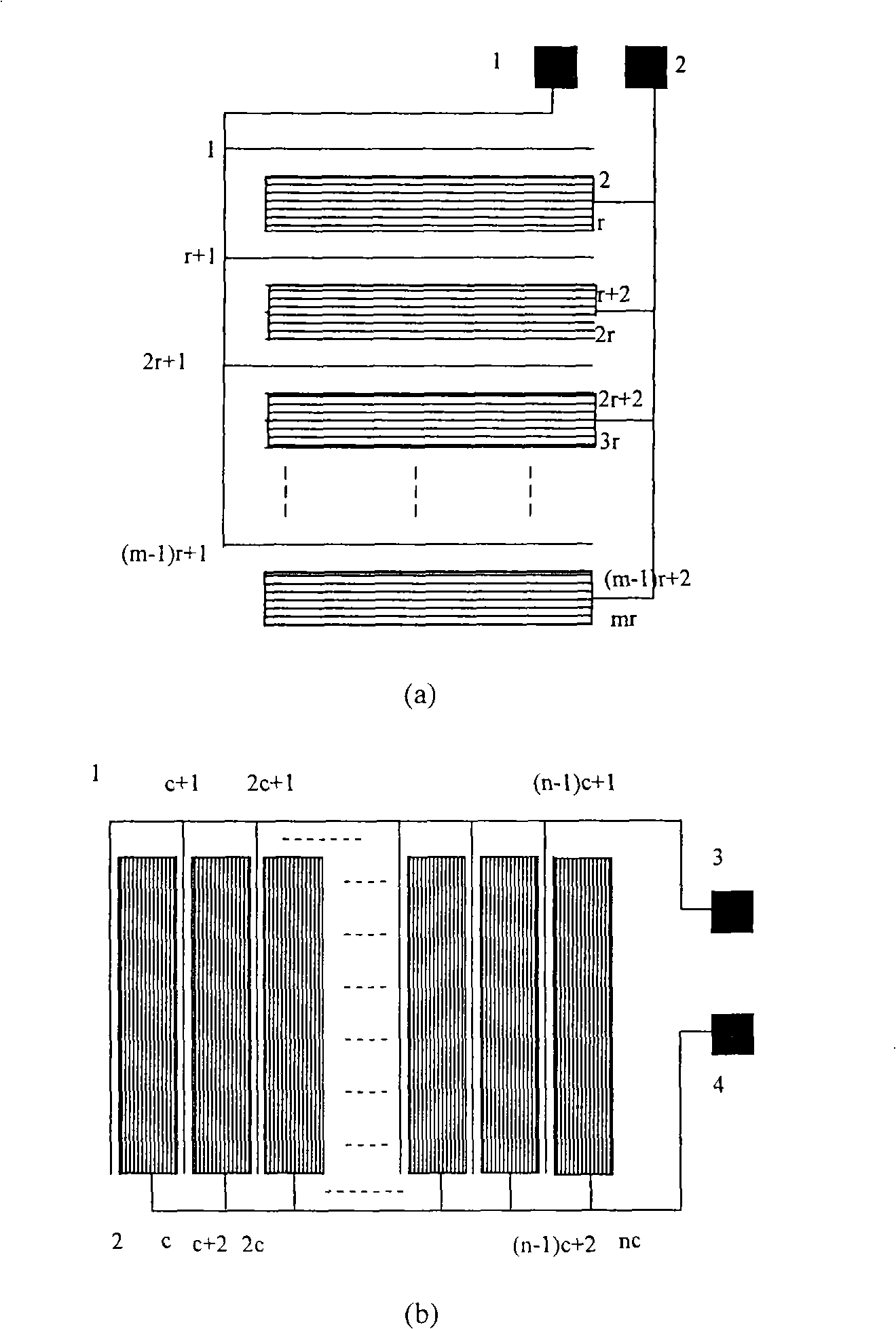

[0017] like figure 1 , 3 shown.

[0018] An experimental test screen for a plasma display, which is composed of a front substrate, a rear substrate and a shadow mask placed in a vacuum chamber, wherein the front substrate, the rear substrate and the shadow mask are not sealed, but are only aligned on all sides, so The rear substrate includes a rear substrate glass substrate, on which a first electrode group is formed, commonly referred to as a column electrode group or an address electrode group, and is formed on a rear substrate glass substrate covering the first electrode group. A dielectric layer, forming a protective film on the surface of the dielectric layer; the front substrate includes a front substrate glass substrate, forming a second electrode group vertically perpendicular to the first electrode group on the rear substrate on the front substrate glass substrate, Usually called row electrode group or scanning electrode group, a dielectric layer is formed on the fr...

Embodiment 2

[0026] like figure 2 , 3 shown.

[0027] The difference between this embodiment and the first embodiment lies in the difference in the way the electrodes are drawn out. figure 2 Another connection method of the electrode contacts of the front substrate and the rear substrate of the plasma display experimental test screen is given, figure 2 (a) is a schematic diagram of the electrode contact connection of the front substrate, figure 2 (b) is a schematic diagram of the electrode contact connection on the rear substrate. according to figure 2 Given the way the electrode contacts are connected, in appropriate waveforms (such as image 3 ) driven by figure 2 Full screen display and dot matrix display can be realized.

[0028] For the points that need to be lit, apply negative voltage pulses to the row electrodes during the addressing period, and apply positive data voltages to the column electrodes. The voltage difference between the two exceeds the ignition voltage to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com