Numerical control method for five-axis processing machine

一种数值控制、加工机的技术,应用在数字控制、程序控制、电气程序控制等方向,能够解决加工物切削等问题

Active Publication Date: 2008-11-19

FANUC LTD

View PDF2 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As a result, there is a problem that cutting to the workpiece occurs, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

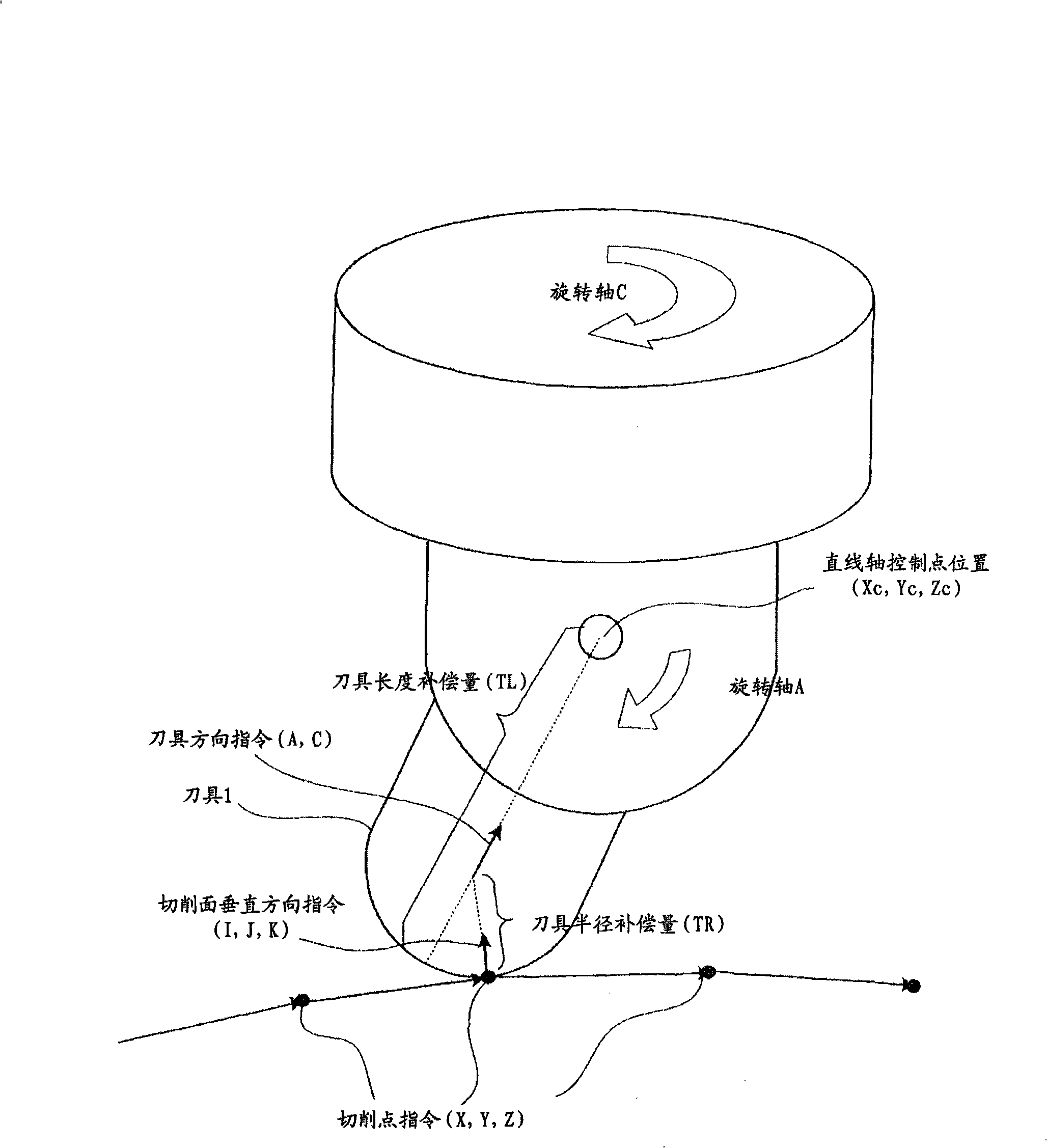

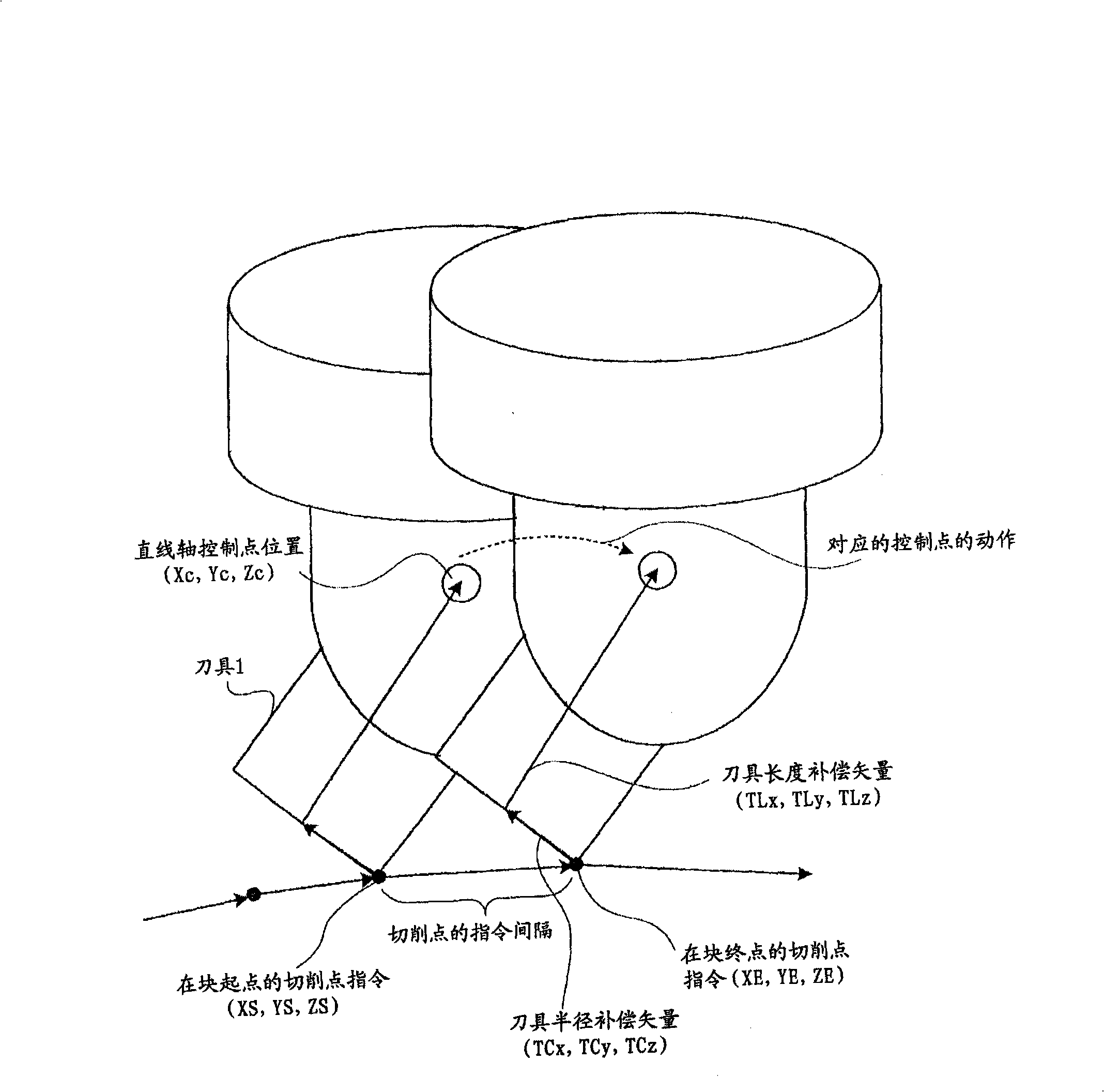

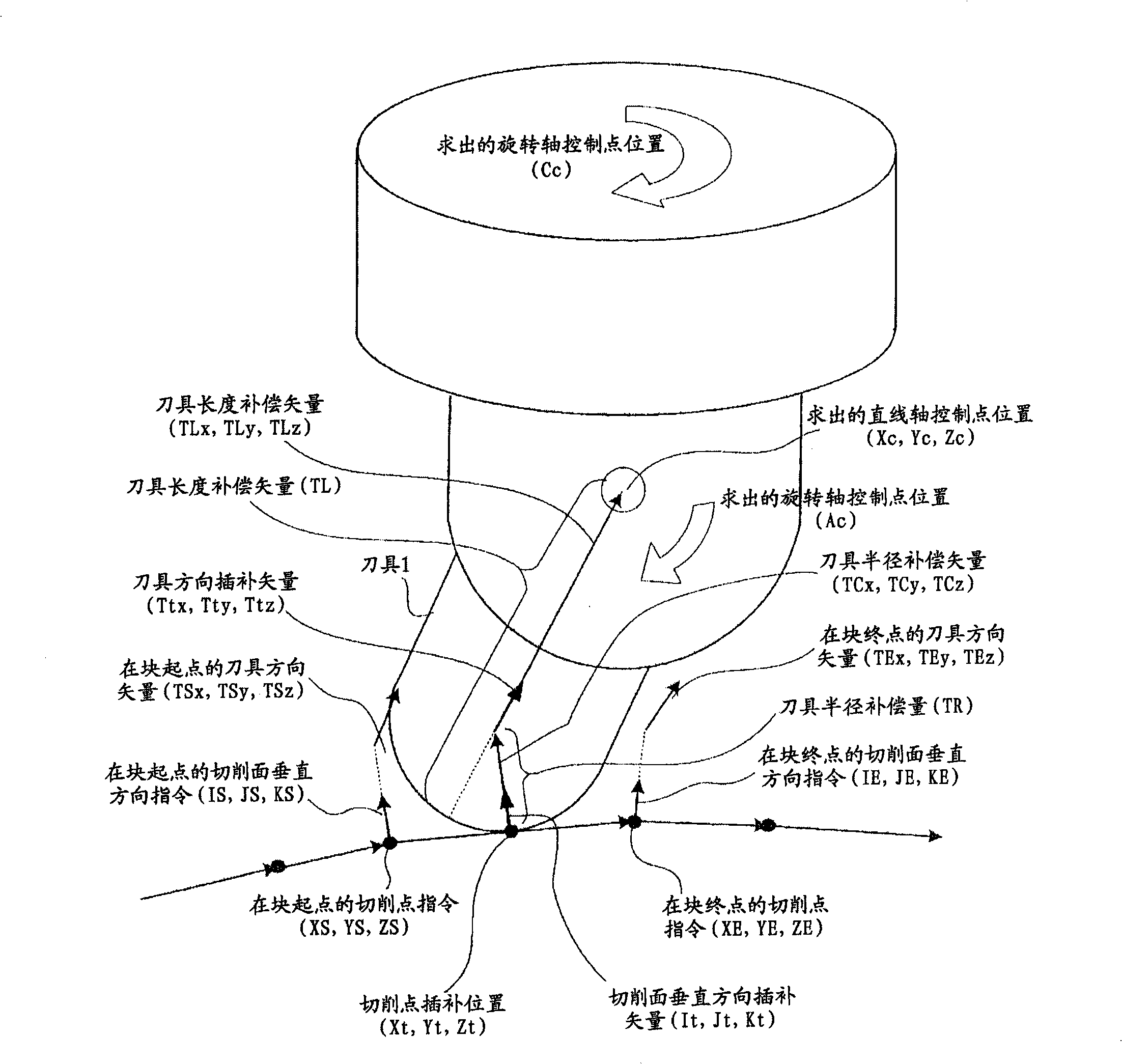

This invention provides a numerical control method for five-axis processing machine. If the angle alpha formed between the interpolated cutting surface perpendicular direction vector (It, Jt, Kt) and the interpolated tool direction vector (Ttx, Tty, Ttz) becomes smaller, movement of a tool becomes unstable. In this case, the tool diameter compensation vector (TCx, TCy, TCz) is set to the tool diameter compensation vector calculated in the immediately previous interpolation cycle, thereby preventing unstable movement. Further, in case of a block instruction where a distance between positions in cutting point instructions is large whereas distance of movement of linear axis control point is small, an excessive cutting may occur. To deal with this problem, movement of linear axis control point in a current block is stopped or converted into linear movement so as to prevent a loop-shaped movement of the linear axis control point.

Description

Numerical Control Method of 5-Axis Machining Machine technical field The present invention relates to a numerical control method for controlling a 5-axis processing machine having two rotary axes and three linear axes, and relates to motion control near a singular point where unstable motion may occur. Background technique There is known a 5-axis machining machine in which a tool moves relative to a workpiece (to-be-processed object) in three linear axis directions, and simultaneously performs machining with the tool tilted relative to the workpiece around two rotational axes. For example, in the processing method of a 5-axis processing machine for processing a curved surface by performing curve interpolation on the basis of command point sequence data generated by CAD / CAM or a profiling device and a command vector sequence indicating the inclination angle of the workpiece and the tool, known A machining method for obtaining a smooth machined surface by interpolating a smo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G05B19/4103

CPCG05B19/4103G05B19/404G05B2219/35158G05B2219/49344G05B2219/50297G05B2219/50336

Inventor 大槻俊明井出聪一郎宫崎健至

Owner FANUC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com