Digital electrichydraulic control system for generating plant turboset

A technology of electro-hydraulic control system and steam turbine unit, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc. It can solve the problems of relatively large speed fluctuations, inconvenient maintenance work, and insufficient control accuracy, and achieve small and accurate switching speed fluctuations Speed and load control, improve the effect of quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0028] Take the digital electro-hydraulic control system of 600MW steam turbine as an example.

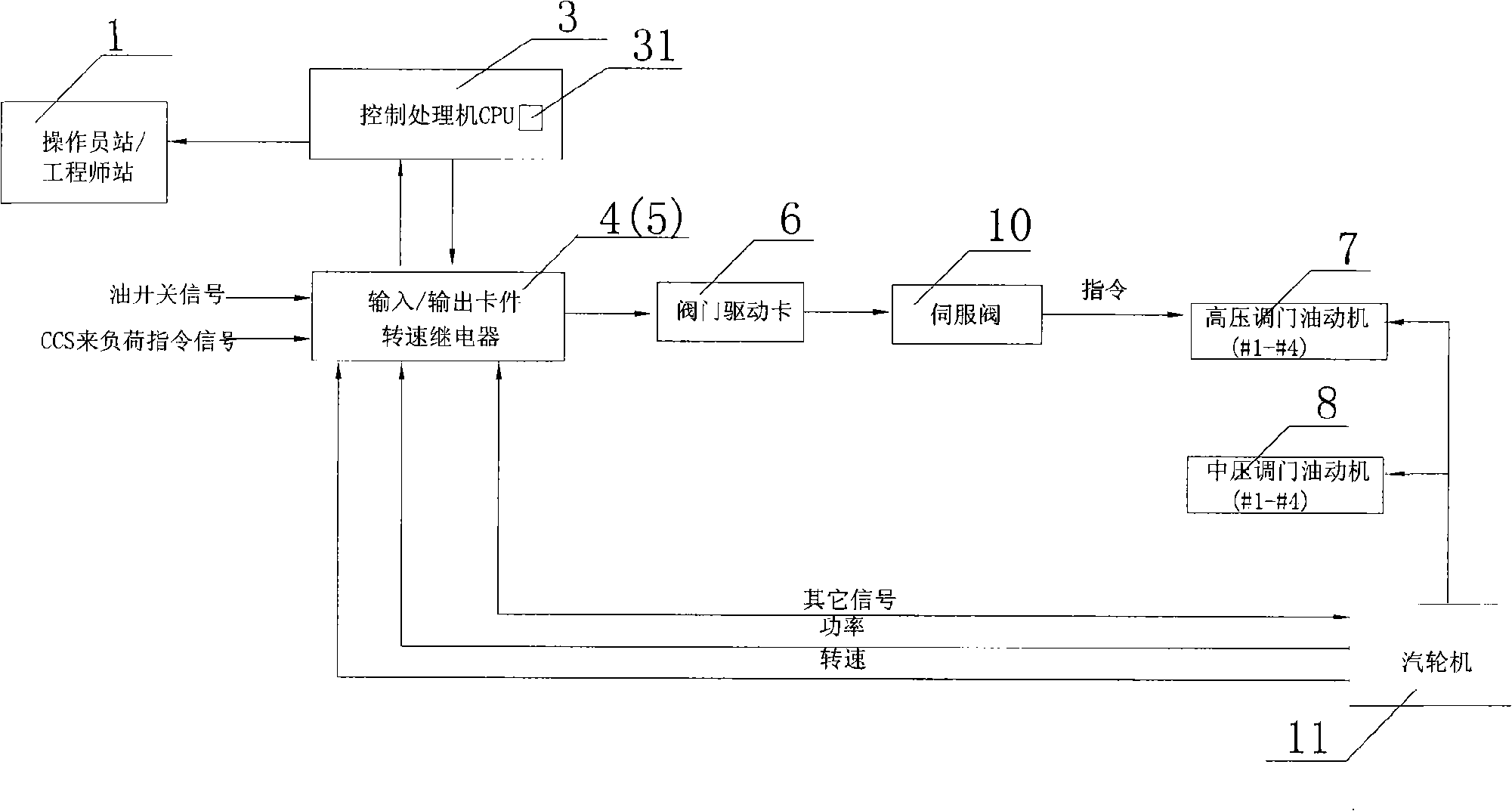

[0029] refer to figure 1 It is a hardware configuration diagram of the control part of the present invention, mainly including operator station / engineer station 1 (2), control processor 3 and 3', input / output card 4 and 4' and other components. Each workstation (operator station / engineer station 1(2)) and control processors 3 and 3' in the system are connected to each other through the node bus, and the control processor and the input / output card are connected through the field bus.

[0030] Operator Station / Engineer Station 1(2) is composed of monitor, keyboard, mouse, printer, etc. The operator obtains information from the monitor of the operator station and issues commands with the keyboard and mouse to control the steam turbine. The engineer station can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com