Brush type road sweeper

A sweeping vehicle and brush-type technology, which is applied in road cleaning, cleaning methods, construction, etc., can solve problems such as troublesome dust discharge operations and shortened service life of transmission devices, and achieve reliable discharge, reduced manufacturing costs, and easy discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, embodiments of the present invention will be described based on the drawings.

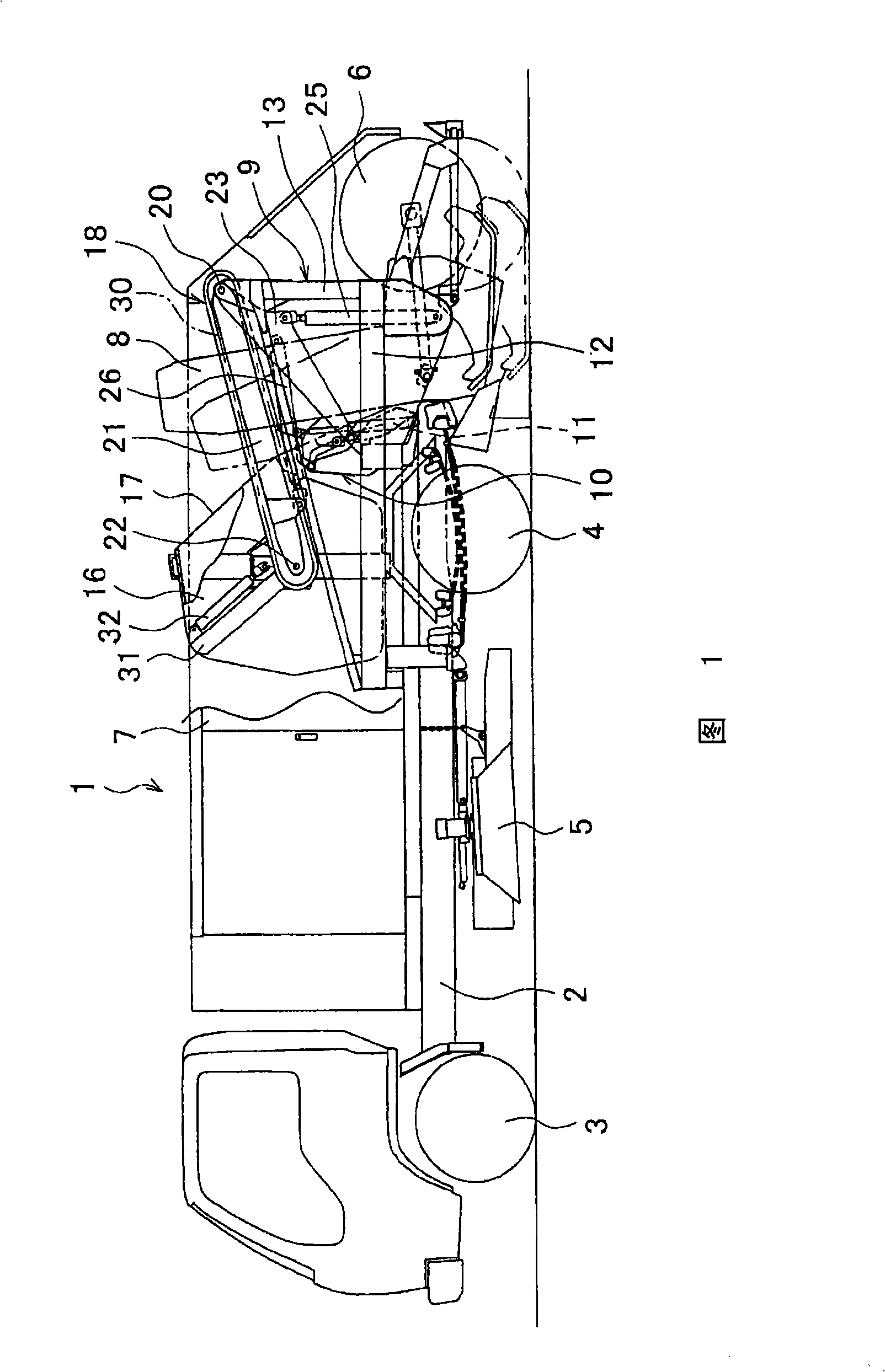

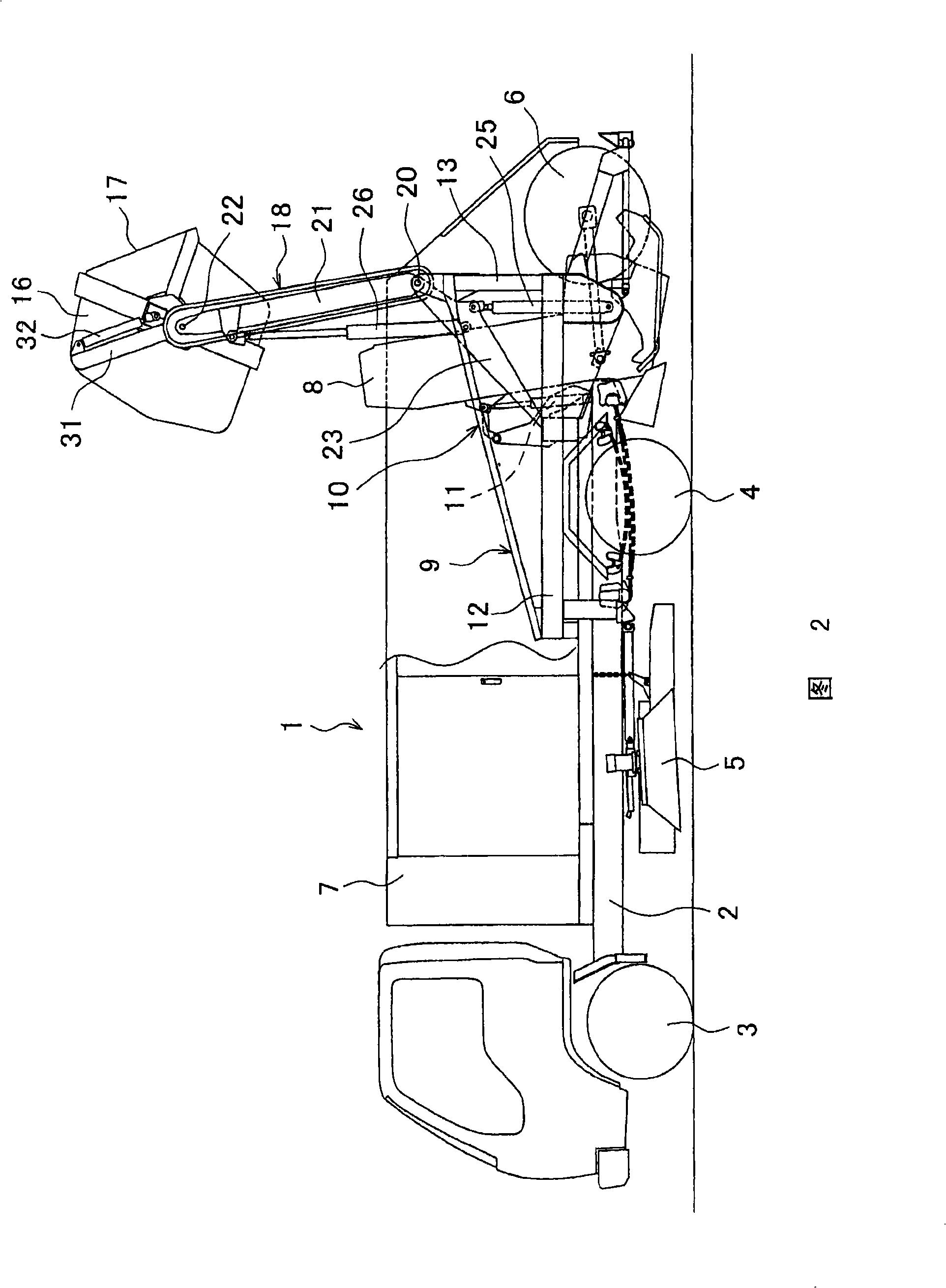

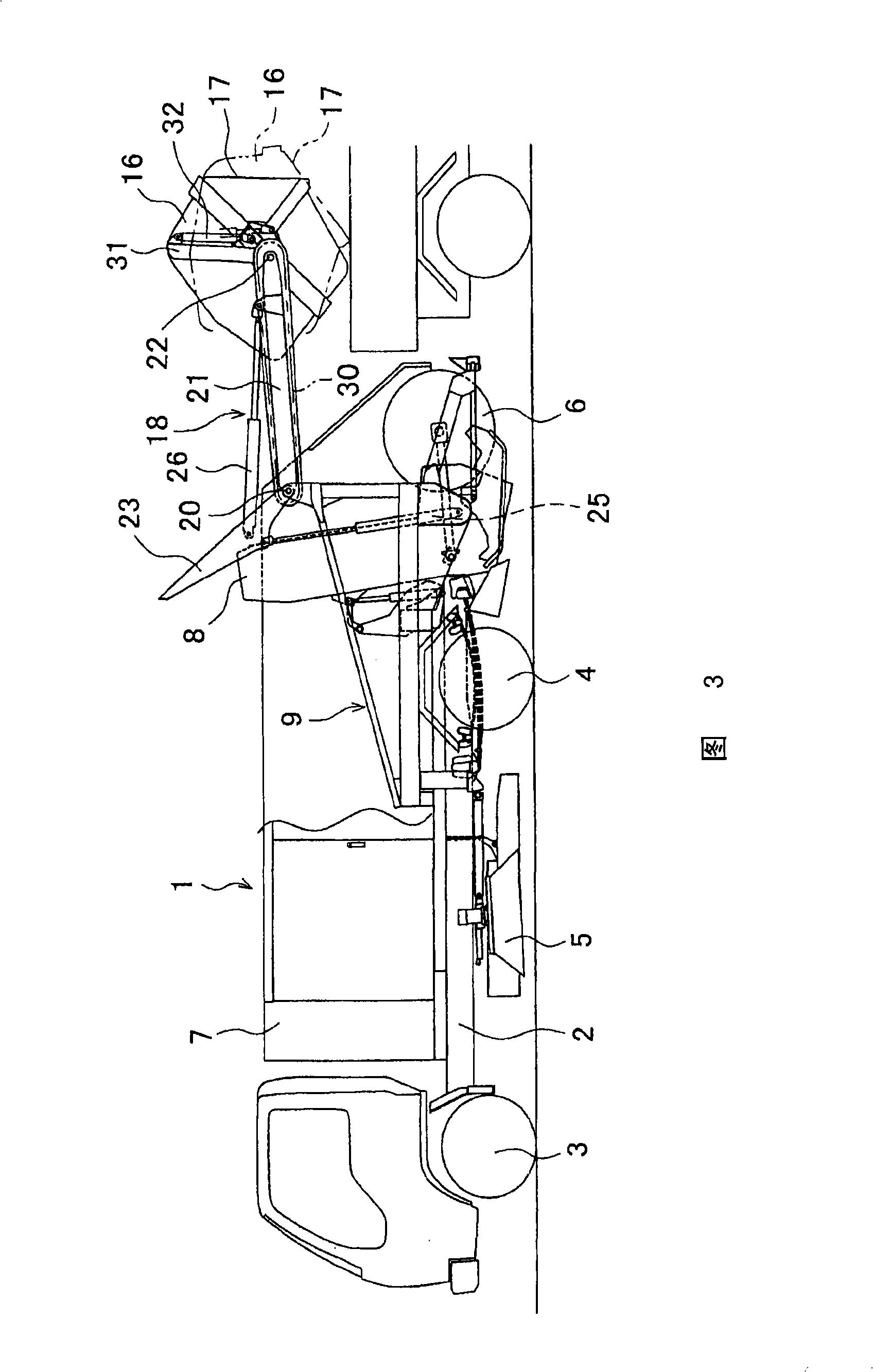

[0035] Figure 1 is an overall view showing an example of the brush type road sweeping vehicle of the present invention. The brush type road sweeping vehicle (hereinafter referred to as "road cleaning vehicle") 1 is located on the left and right sides of the chassis 2 and on the front and rear wheels 3, 4 (designed The left side of Figure 1 is the front), a pair of side brushes 5, 5 are rotatable and movable up and down. On the other hand, a main brush 6 is arranged behind the chassis 2, which will be swept closer by the side brushes 5, 5. The dust on the road surface reaching the lower center of the chassis 2 is swept up and forward by the main brush 6. Reference numeral 7 is a cover covering the upper, right and left sides of the chassis 2 and the upper side of the main brush 6.

[0036] The main brush 6 is rotatably assembled behind the lower end of the conveyor 8 installed in a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com