Sectional polyester chip solid phase viscosity-increasing reactor

A technology of polyester chip and solid-phase thickening, which is applied in the field of segmented polyester chip solid-phase thickening reactor, which can solve the problems of low heat transfer efficiency, small heat transfer coefficient, slow reaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

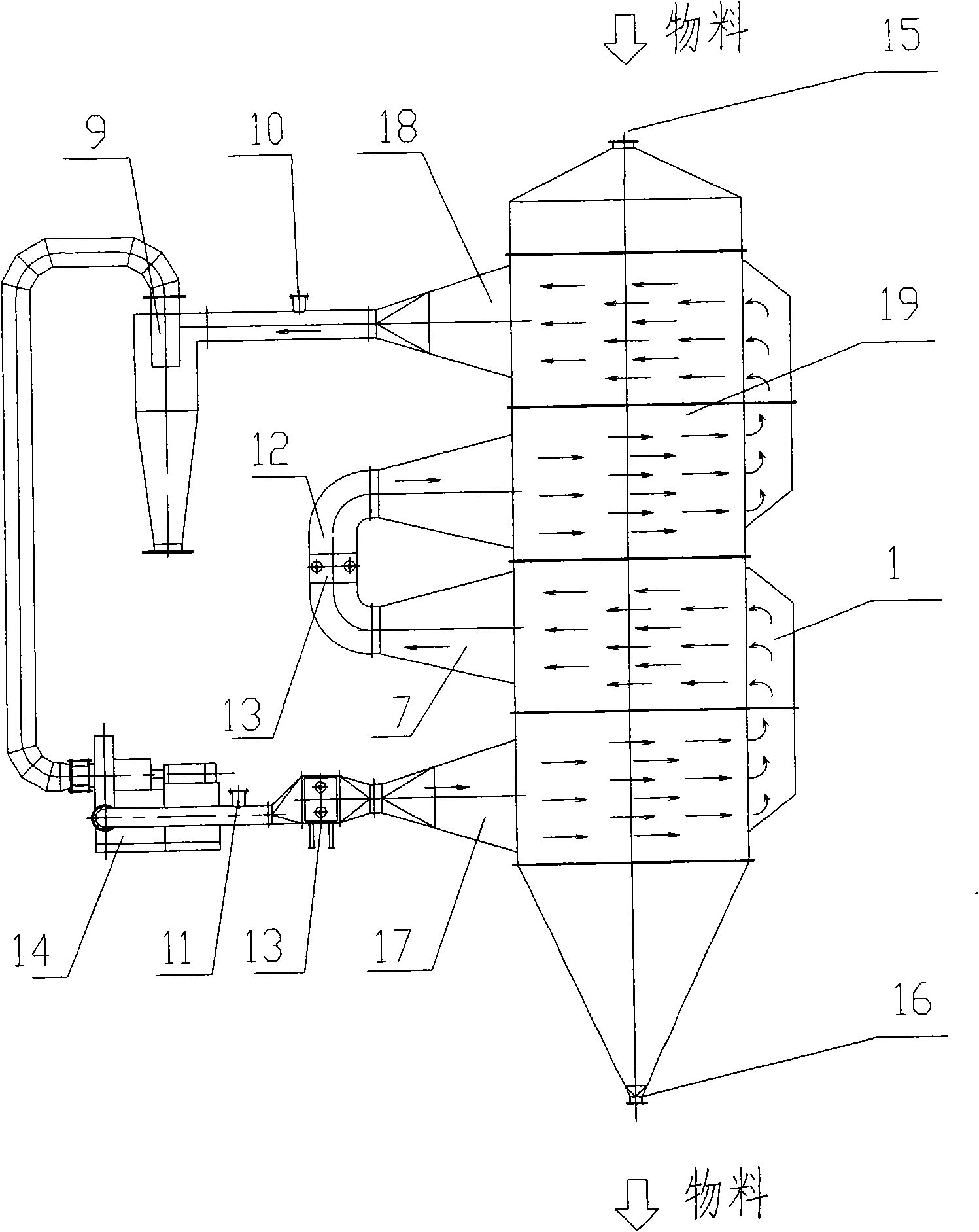

[0026] The present invention comprises a vertical reaction tower, and a material inlet 15, a material outlet 16, an air inlet 17 and an air outlet 18 arranged on the reaction tower. Next, flow out from the material outlet 16 at the bottom to complete the raising of the material viscosity. The main flow of hot inert gas enters the reaction tower from the air inlet 17 at the bottom, and is discharged from the air outlet 18 upwards against the direction in which the material descends. The air outlet 18 is connected with the purification device 9 through the air duct, and the air duct between the air outlet 18 and the purification device 9 is provided with a gas replenishing air duct 10, and the purification device 9 is connected with the blower fan 14, the heater 20 and the air inlet through the air duct. 17 forms a circuit, wherein on the air duct between the fan 14 and the heater 20, an exhaust air duct 11 is arranged. In specific implementation, it can be slightly different a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com