Construction method for underground grounded screen

A construction method and grounding grid technology, applied in the direction of connection, connection contact material, static electricity, etc., can solve the problems of low construction efficiency, increased construction cost, theft, etc., achieve good welding quality, good grounding effect, and prevent theft Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

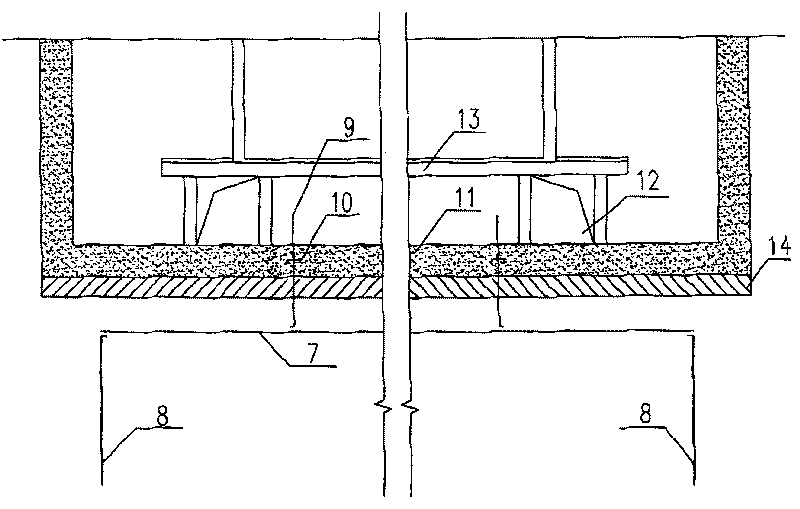

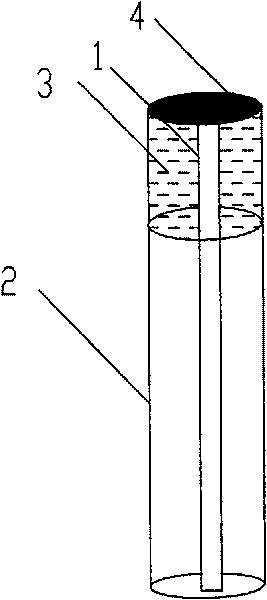

[0045] A method for constructing a subway grounding grid, comprising the following steps: determining the exact installation positions of a horizontal grounding body 7 and a vertical grounding body 8; excavating trenches; making and installing the horizontal grounding body 7 and the vertical grounding body 8; installing grounding lead wires 9 ; Trench backfill compaction.

[0046] The horizontal grounding body 7 adopts a copper row, the vertical grounding body 8 adopts a copper tube, and the grounding lead wire 9 adopts a copper row.

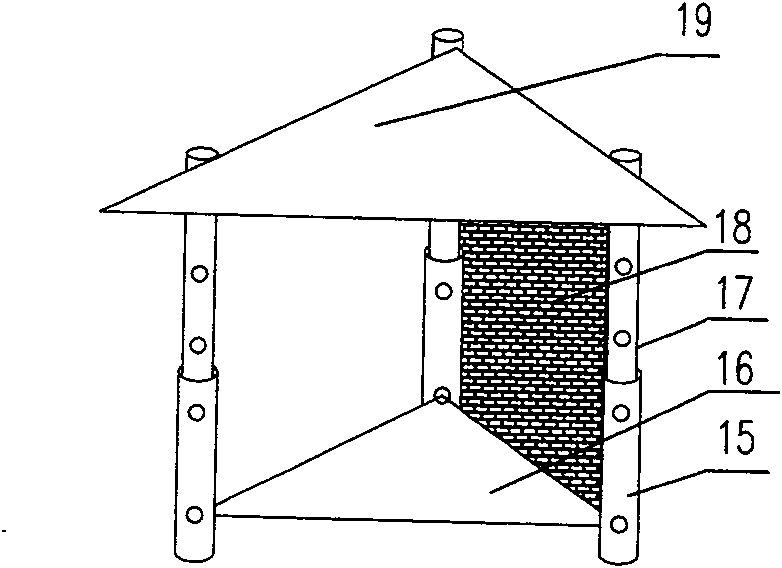

[0047] like figure 1 As shown, there are vertically downward vertical grounding bodies 8 at both ends of the horizontal grounding body 7, the upper end of the horizontal grounding body 7 is connected to the vertically upward grounding body lead-out line 9, the horizontal grounding body 7 is backfilled with plain soil, and the upper end of the horizontal grounding body 7 is a pad Layer 14, the upper end of the cushion layer 14 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com