Slip ring novel structure of large medium-size coiling motor

A wire-wound motor and a new structure technology, applied in the direction of circuits, current collectors, electrical components, etc., can solve the problem of insufficient stability of squirrel cage motors, achieve the effects of reducing carbon powder adhesion, improving stability, and reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

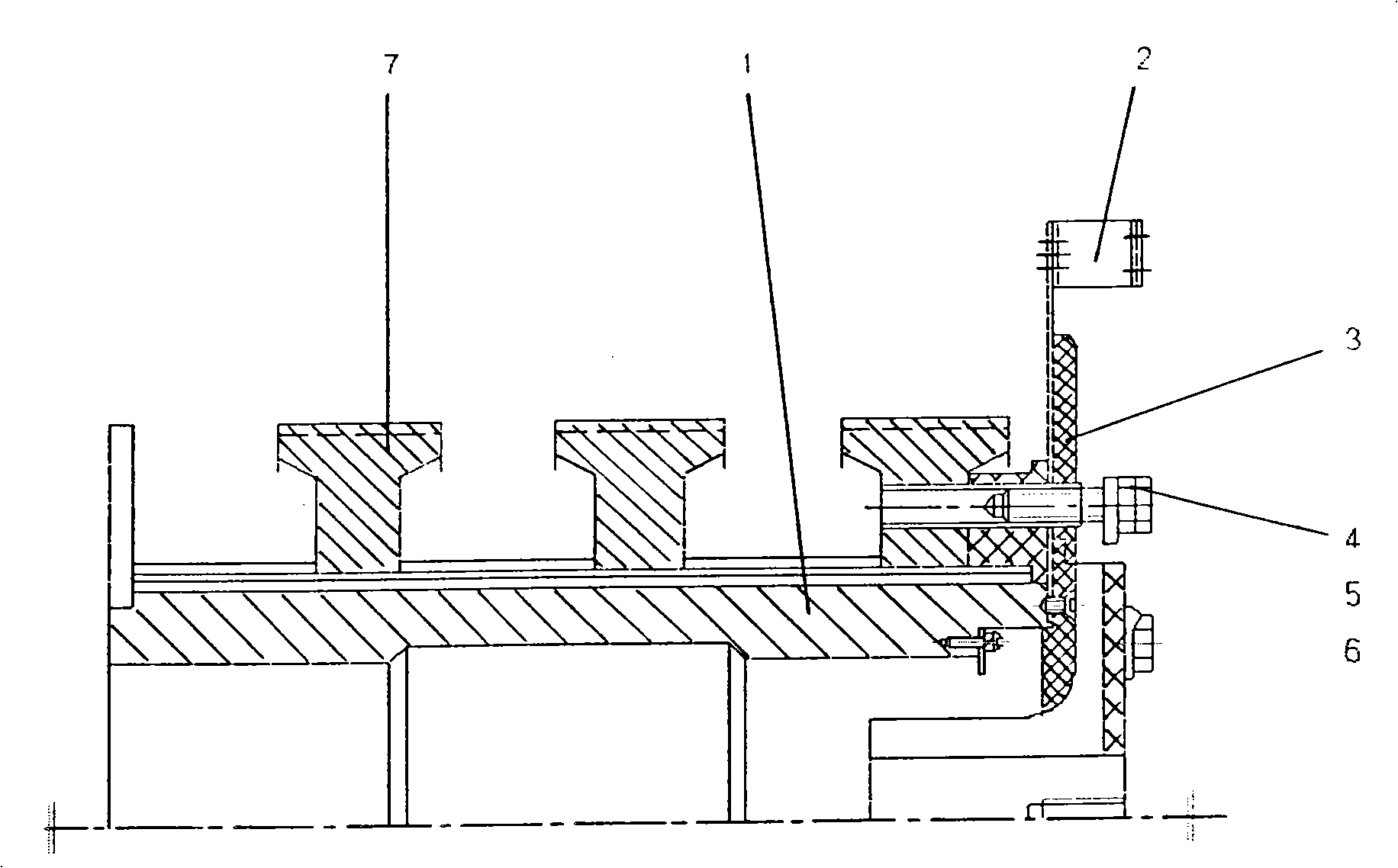

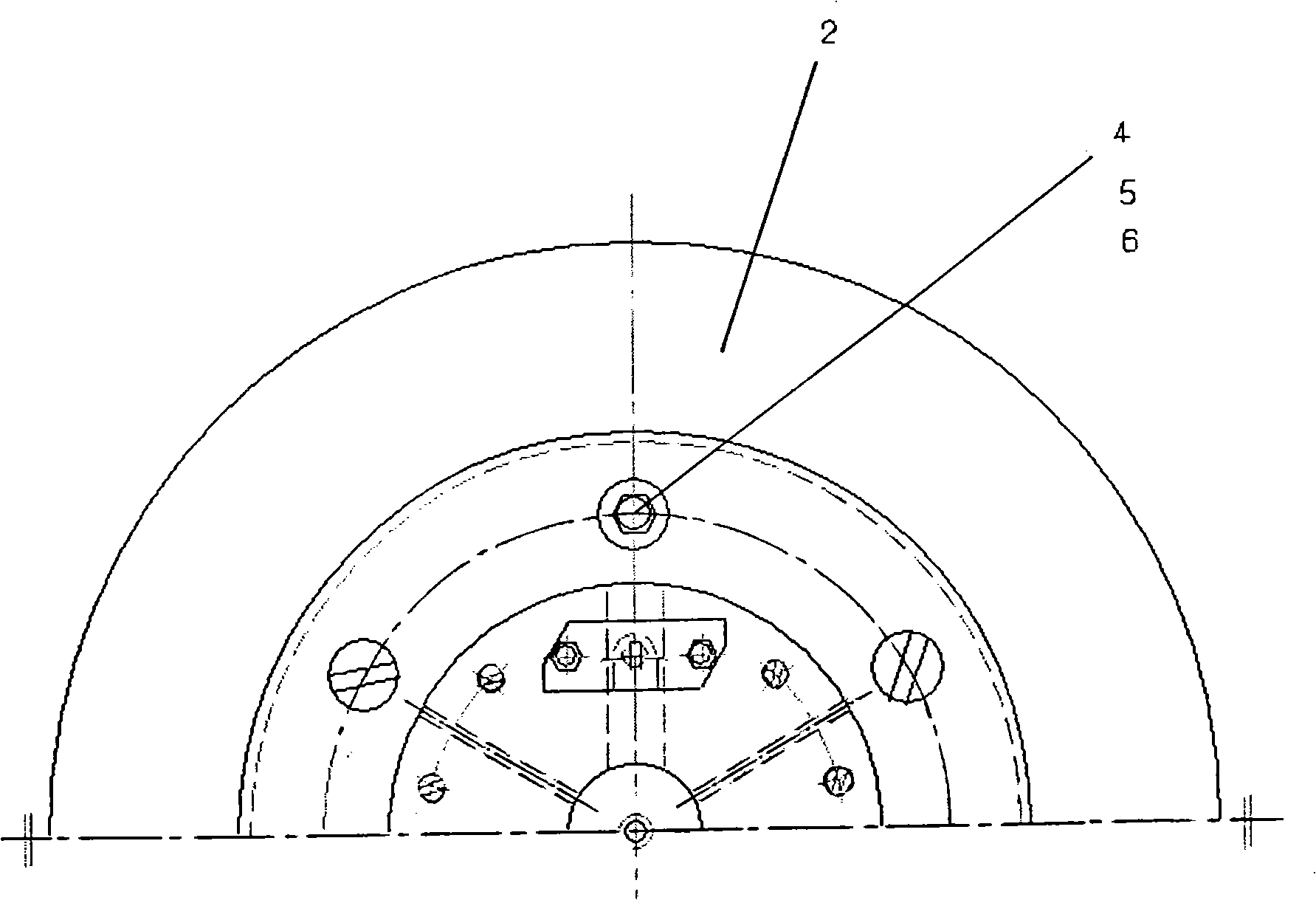

[0013] Please refer to the attached figure 1 It is the main sectional structure schematic diagram and the attached figure 2 As shown in the left view structural diagram of the present invention, a new structure of a slip ring of a large and medium-sized winding motor, the sleeve 1 is shrunk on the shaft, and an inward special for The fan 2 for slip ring cooling, the fan 2 is fixed on the slip ring 7 through the plug 3, the bolt 4, the nut 5, and the washer 6. By installing the fan 2, the wind speed at the slip ring 7 can be increased to strengthen the cooling of the slip ring 7 and increase the slip ring. Ring 7 operational reliability.

[0014] The fan 2 is a circular fan with a plurality of blades, and a plurality of slip rings 7 are disposed within the coverage area of the circular fan 2 as a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com