Method for preventing shutter malposition of gate valve

A gate and gate valve technology, which is applied in the field of preventing gate misalignment of gate valves, can solve the problems of dislocation of wedges and gates, easy separation of gates, difficult assembly work, etc., so as to improve integrity, prolong service life, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

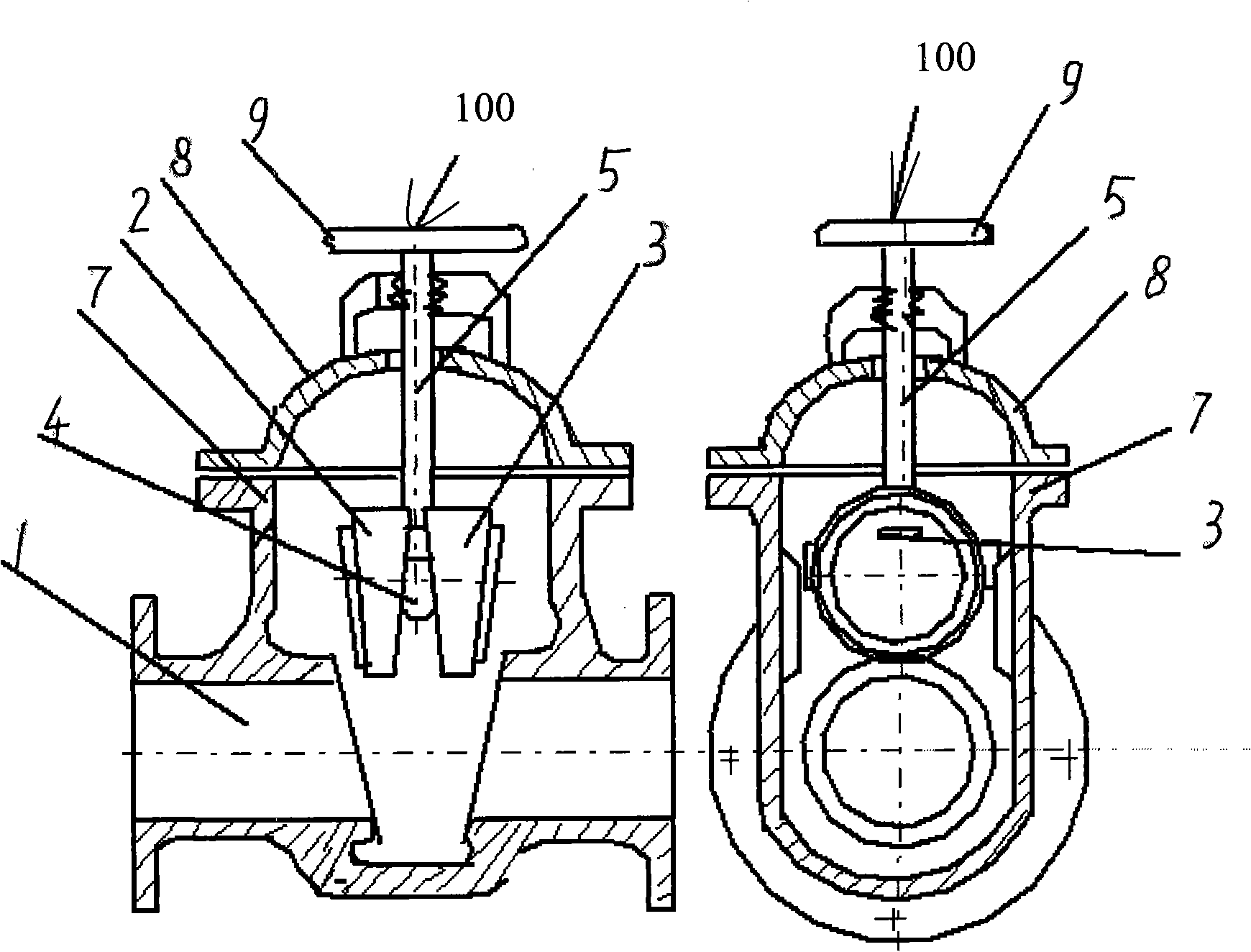

[0027] like Figure 1 to Figure 8 shown. A method for preventing dislocation of gate valves, the method comprising the following steps:

[0028] A: An associated piece 3 is set between the gate plates 2 of the liquid flow channel 1 of the sealing gate valve 100;

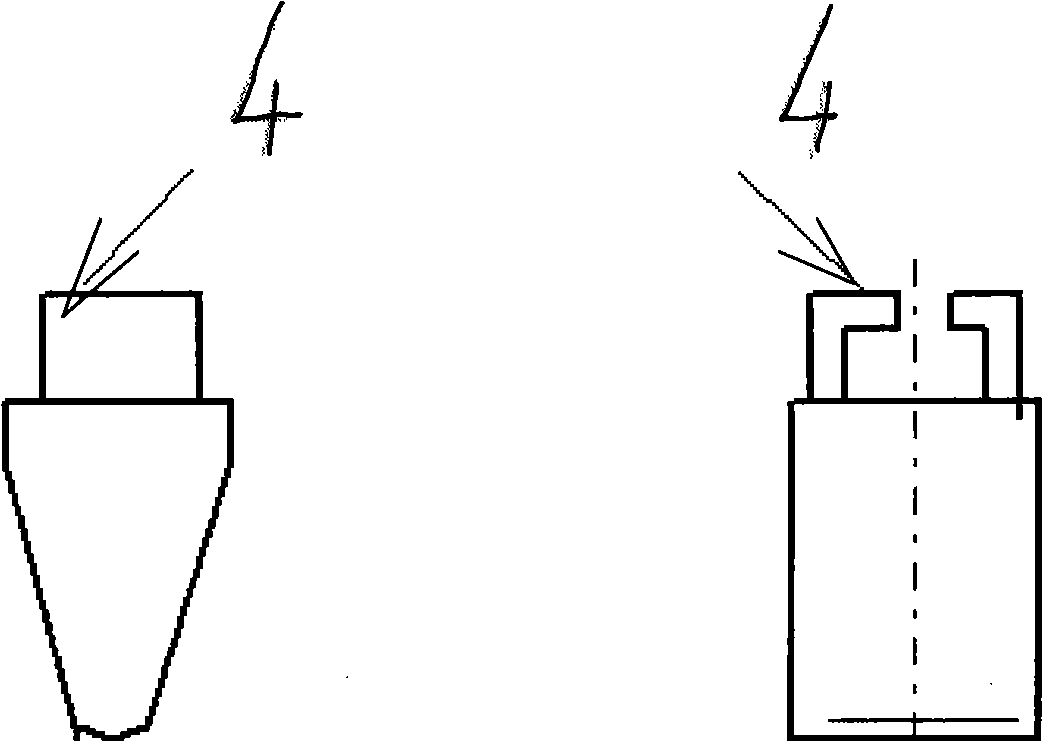

[0029] B: Assemble the gate plate 2 with the associated part 3, the wedge 4, and the valve stem 5 to form the valve core 6;

[0030] C: Put the valve core 6 obtained in step B into the matching valve body 7;

[0031] D: Install the valve cover 8 and its hand wheel 9 corresponding to the valve body 7 .

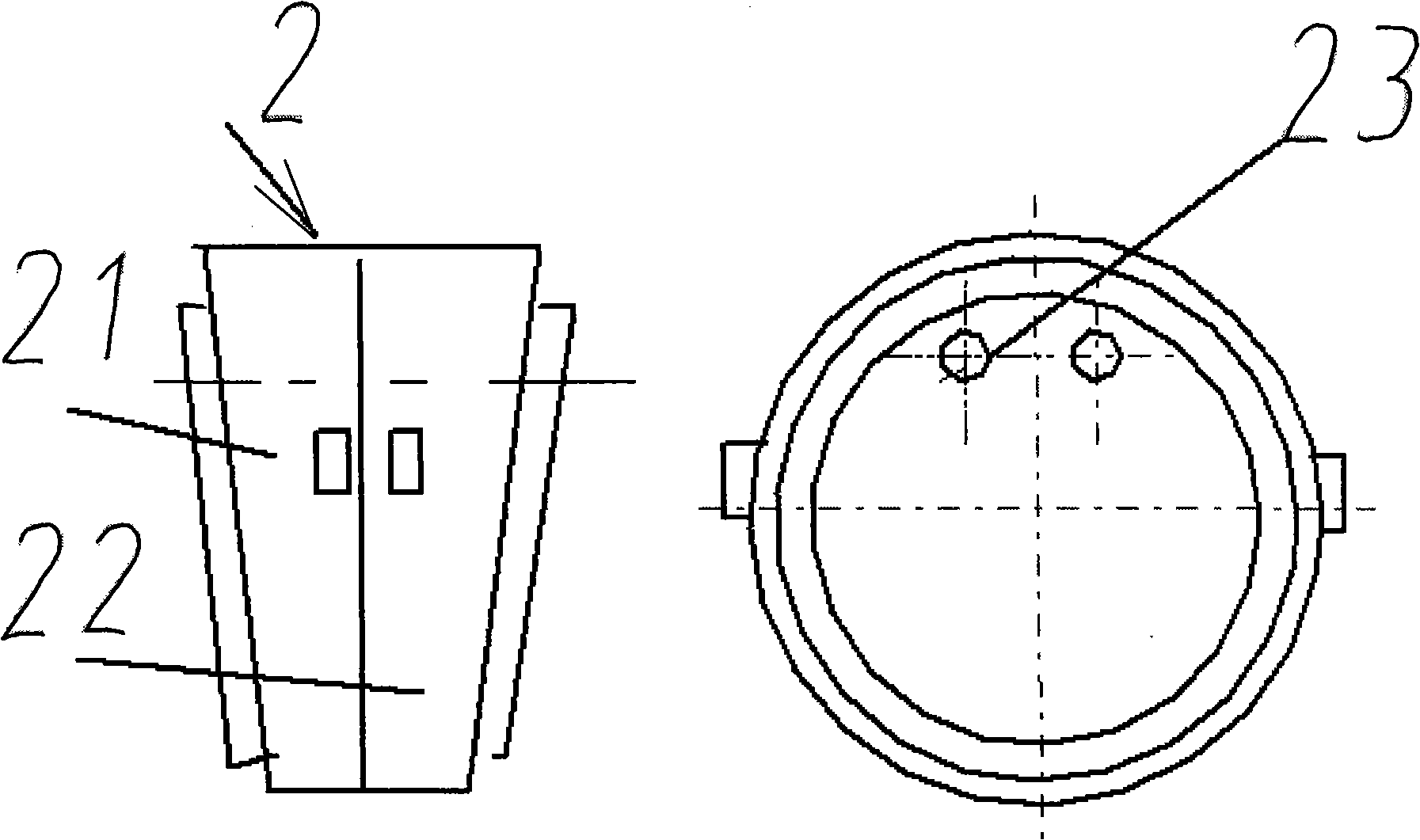

[0032] In step A, the gate plate 2 is a first gate plate 21 and a second gate plate 22 that are relatively combined, and an associated piece 3 is provided between the first gate plate 21 and the second gate plate 22, the The first gate 21 and the second gate 22 move synchronously,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com