Optical elements for high contrast applications

A technology of optical components and multi-layer optical films, which can be used in optical components, optics, instruments, etc., and can solve problems such as poor performance of front projection screens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

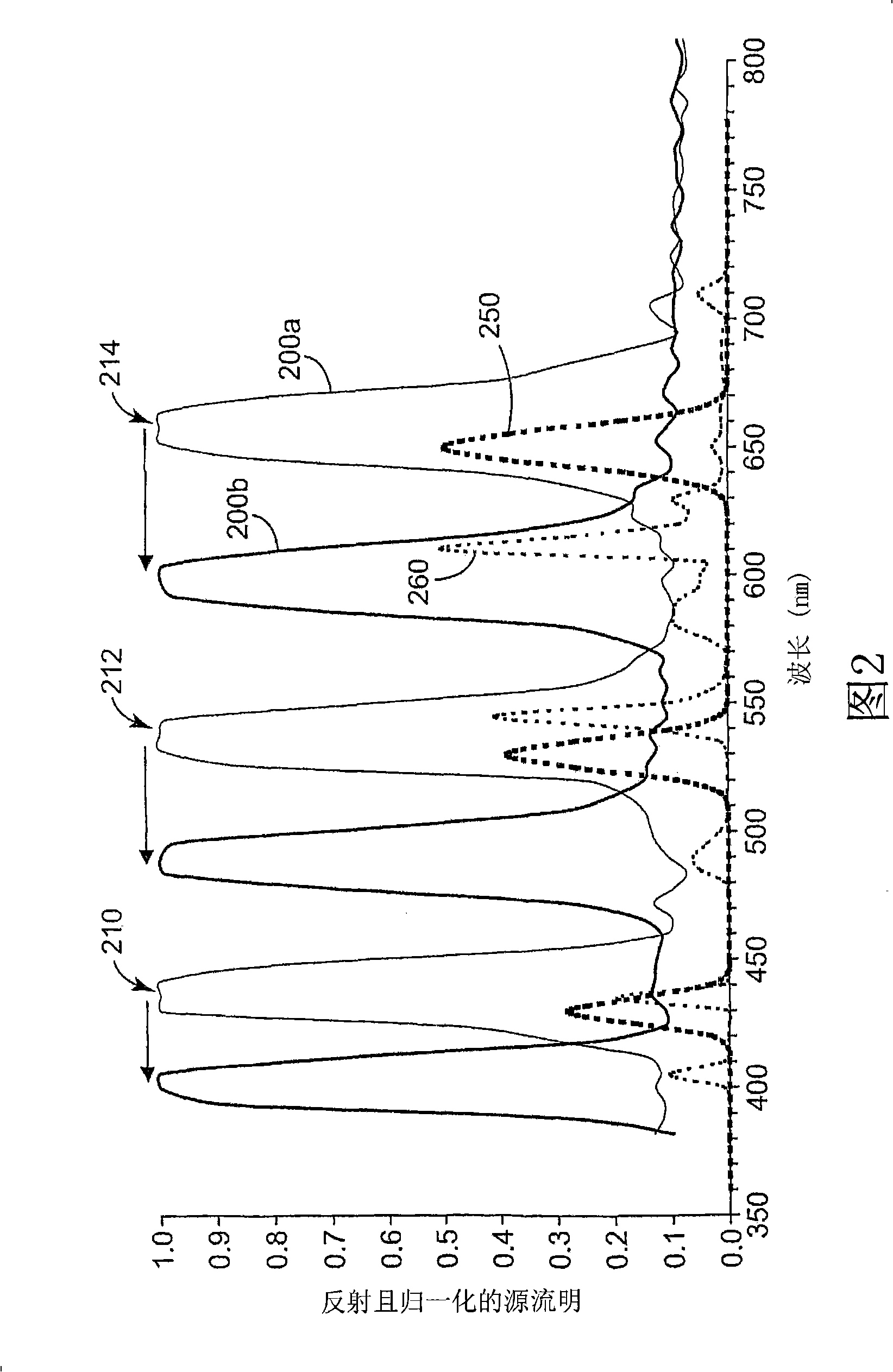

example 1

[0077] In Example 1, the computational construction (ie, model design) included the optical elements of a multilayer optical film mirror. The MOF structure consists of 3 quarter-wavelength stacks of coherent multilayer optical films, each stack including 160 layers of polycarbonate (material 1) and PMMA (material 2). All materials in Example 1 are isotropic, and their refractive index n 1 = 1.579, and n 2 = 1.495. The lower index PMMA layer is at the air to interference stack reflector interface. These settings reduce the degree of reflection in the wavelength region between the reflection bands of the interference stack. Each set of coherent stacks of alternating polymer microlayers (herein referred to as "blue light reflective interference stacks", "green light reflective interference stacks", etc.), is designed to have a reflection band around a designed visible wavelength. Equation 1 represents the center wavelength λ of the first-order harmonic (m=1) reflection band ...

example 2

[0090] In Example 2, a MOF reflective polarizer was computationally constructed. The MOF structure consists of three coherent multilayer quarter-wavelength stacks, each containing 160 birefringent polyethylene naphthalate (PEN; material 1) and non-birefringent copolymer microspheres of PEN. layer (co-PEN; material 2), the refractive index n of the polyethylene naphthalate microlayer in the stretching direction 1,stretch =1.757, the refractive index n in the harmonic direction 1,match = 1.614, the refractive index n of its non-birefringent copolymer 2 = 1.612. The lower index co-PEN layer is assumed to be at the air-to-interference stack interface. This reduces the degree of reflection in the wavelength region between the reflection bands of the interference stack. As in the case of Example 1 with MOF mirrors, each coherent interference stack is designed to have a reflection band at a designed visible wavelength to harmonize the light output spectrum of the projector. Equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com