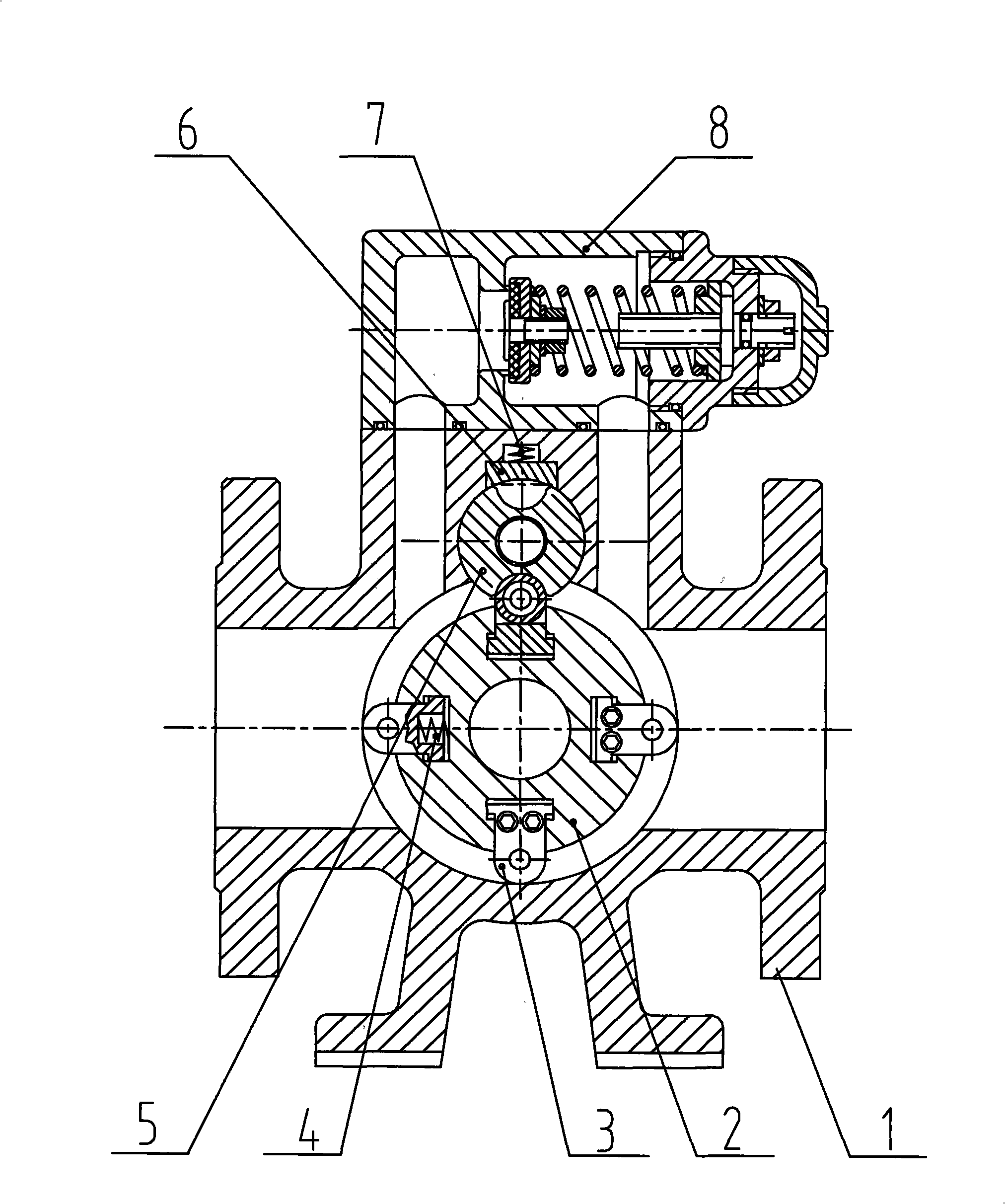

Rotor pump with rotary slices

A rotor pump and rotary vane technology, applied in rotary piston pumps, rotary piston machines, pumps, etc., can solve the problems of complex rotor structure, unbalanced force of rotor eccentric rotation, etc. The effect of a wide range of media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

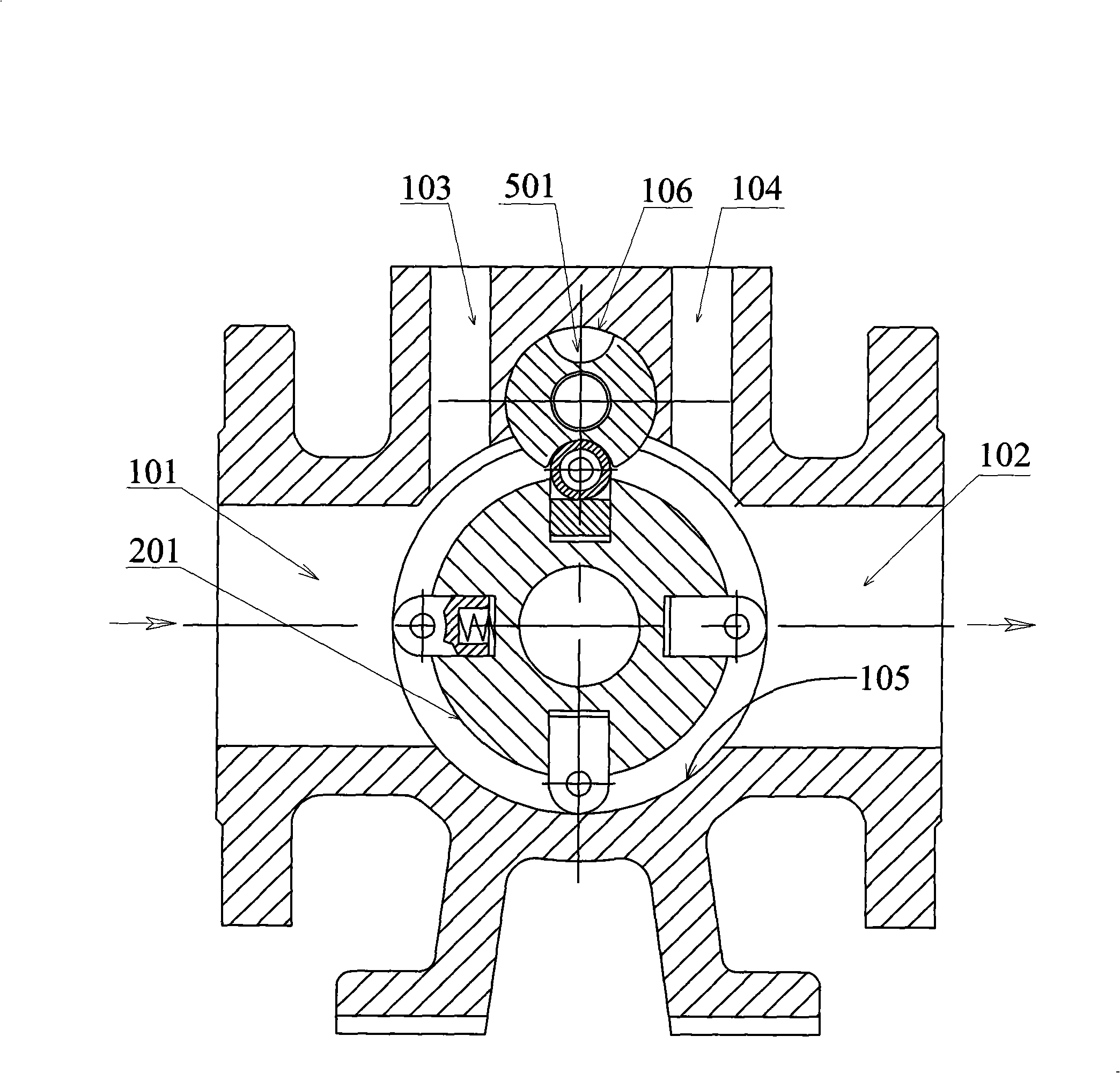

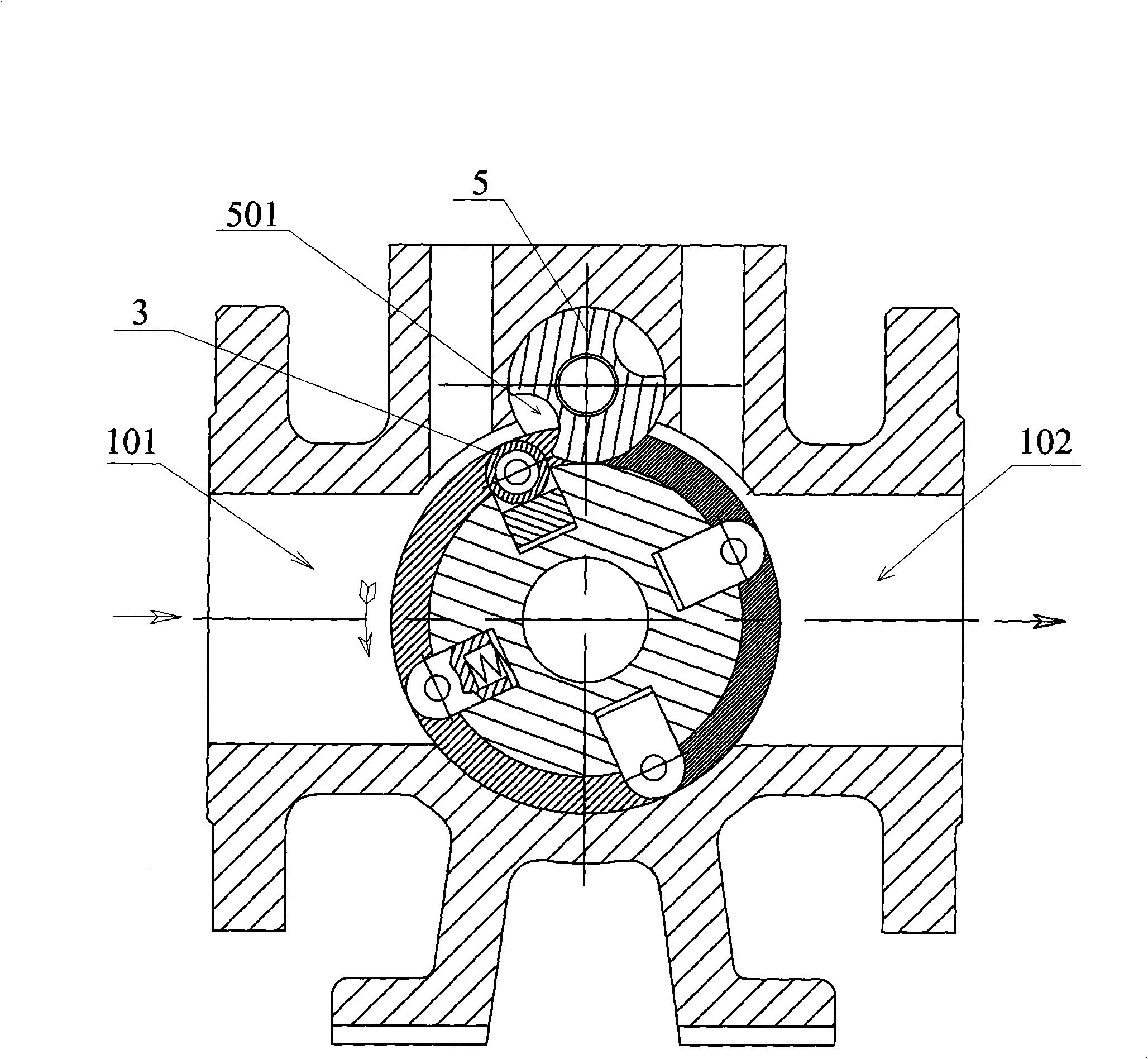

[0017] The preferred embodiments of the present invention will be described in detail below. In the drawings, the same parts are denoted by the same reference numerals.

[0018] In the term "rotary vane" used in the present invention, its shape should be reasonably determined according to its role in the present invention. For example, in the preferred embodiment of the present invention, it is composed of a base, lugs, rollers, etc. The formed structure, of course, in other embodiments of the present invention, it may also be a single structure. In the present invention, the described "rotor" is only used as an embodiment for forming the "protruding surface", and the protruding surface can also be formed by other methods, such as protruding from the outer circumferential surface of the larger rotor. In the following description, although "large" and "small" are used to describe certain parts, for example, large shaft, large rotor, small shaft, small rotor, but only for the conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com