Automatic yarn changing device

A technology of automatic thread adjuster, applied in the field of thread adjuster, can solve the problems of difficult replacement of wearing parts, complex structure, large holes, etc., and achieve the effect of easy installation and maintenance, compact and precise structure, and reduced cloth defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

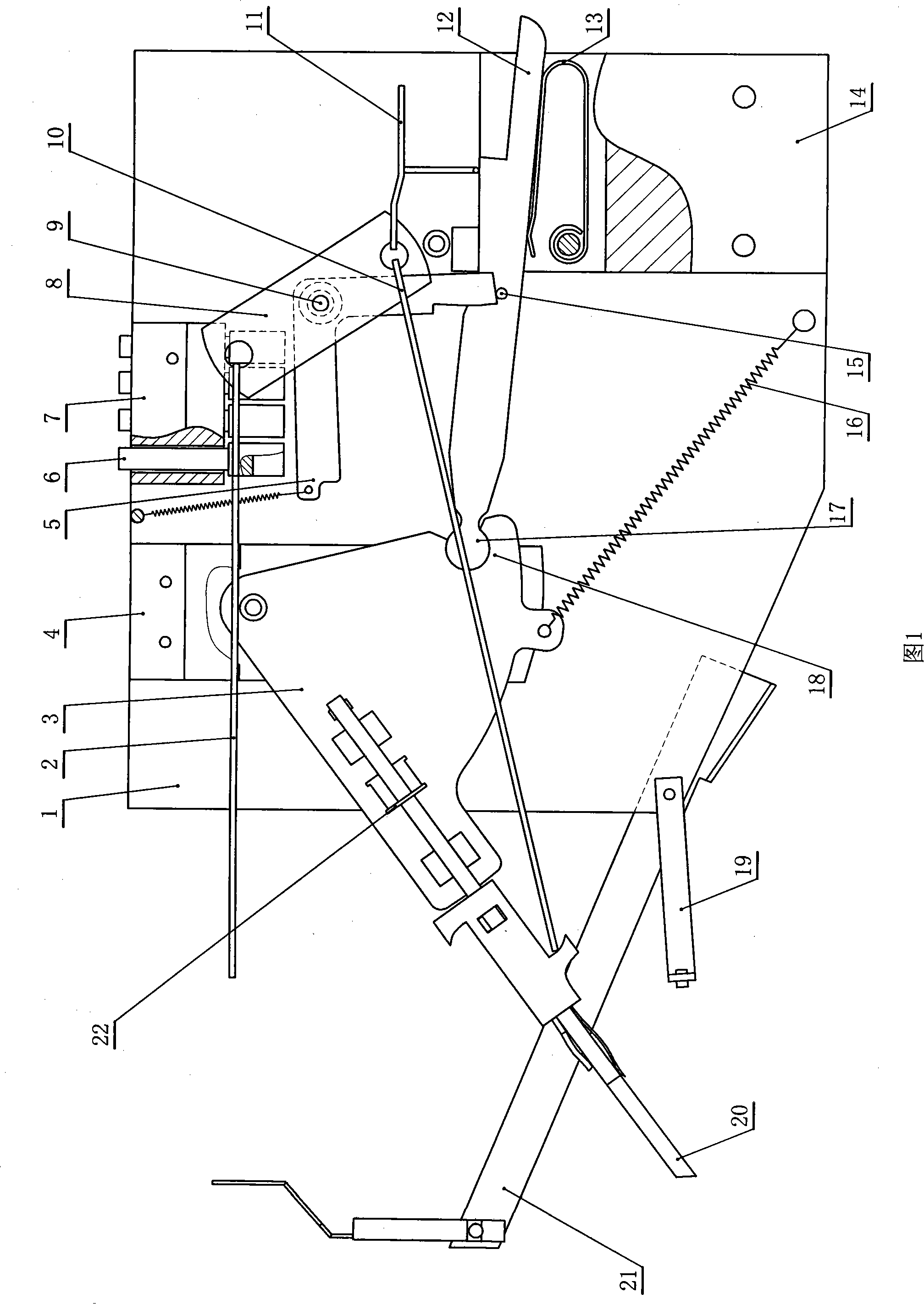

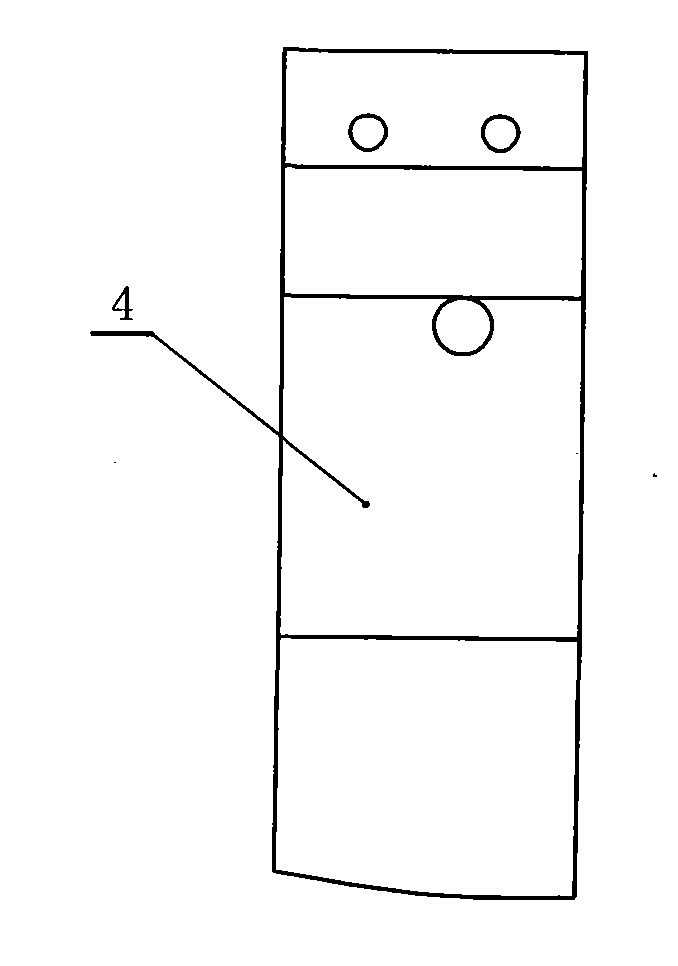

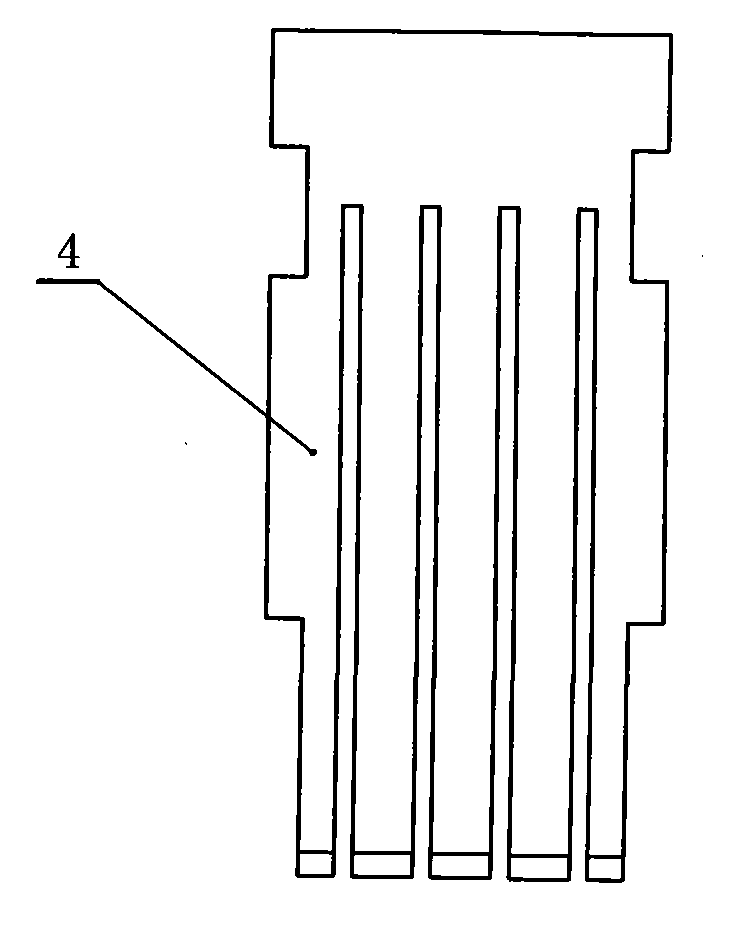

[0052] An automatic thread adjuster, such as figure 1 As shown, it includes an outer cover 1, and the outer cover 1 is fixedly equipped with a knife rest holder 4 (see figure 2 , image 3 ), yarn selection fixing seat 7, connecting seat 14 (see Figure 4 , Figure 5 ), yarn guide frame 19 (see Figure 24 ), yarn changing frame 21 (see Figure 25 , Figure 26 ), there is a through hole on the yarn selection holder 7, and the yarn selection rod 6 is plugged in the through hole (see Figure 20 ); There is a through groove on the connecting seat 14, and the tension spring 13 is installed in the through groove (see Figure 19 ); the outer cover 1 between the yarn selection fixed seat 7 and the connecting seat 14 is fixedly equipped with a main shaft, and the upper and lower ends of the main shaft are relatively rotated and are respectively sleeved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com