Harmless clean fracturing fluid

A technology for cleaning fracturing fluid and quaternary ammonium salt, applied in the field of fracturing fluid, can solve the problems of residual microgel, high cost of sodium salicylate, increase the cost of clean fracturing fluid, etc. sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

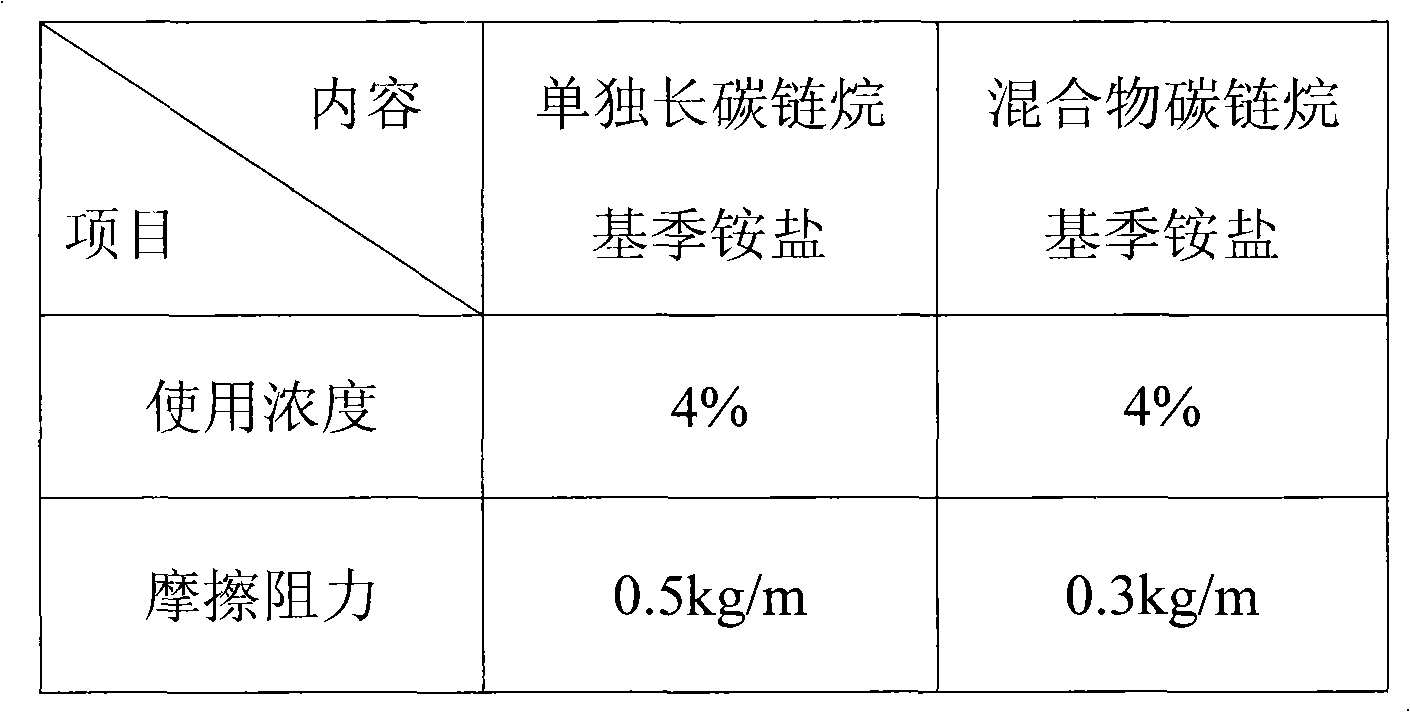

Image

Examples

Embodiment 1

[0021] Select 10 g of dedecyl dimethyl ammonium chloride, 30 g of tetradecyl dimethyl ammonium chloride, 60 g of hexadecyl dimethyl ammonium chloride, 50 g of potassium hypochlorite, and 17 g of ethanol. Add the above substances into water one by one under stirring conditions and mix thoroughly. When it is made into a 4% aqueous solution, the -1 , sheared for 10 minutes, the viscosity is 73mPa·s, has high viscoelasticity, has sand-carrying function, and fully meets the sand-carrying requirements of oil and gas field fracturing fluid.

Embodiment 2

[0023] Select 10 g of dodecyl dimethyl ammonium chloride, 30 g of tetradecyl dimethyl ammonium chloride, 60 g of hexadecyl dimethyl ammonium chloride, 67 g of potassium hypochlorite, and 17 g of ethanol. Add the above substances into water one by one under stirring conditions and mix thoroughly. When it is made into a 4% aqueous solution, the -1 , sheared for 10 minutes, the viscosity is 85mPa·s, has high viscoelasticity, has the function of carrying sand, and fully meets the sand carrying requirements of oil and gas field fracturing fluid.

Embodiment 3

[0025] Select 10 g of dedecyl dimethyl ammonium chloride, 30 g of tetradecyl dimethyl ammonium chloride, 60 g of octadecyl dimethyl ammonium chloride, 67 g of potassium hypochlorite, and 30 g of isopropanol. Add the above substances into water one by one under stirring conditions and mix thoroughly. When it is made into a 4% aqueous solution, the -1 , sheared for 10 minutes, the viscosity is 90mPa·s, has high viscoelasticity, has the function of carrying sand, and fully meets the sand carrying requirements of oil and gas field fracturing fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com