Mould for processing glass container

A technology for processing glass and containers. It is applied in the field of molds for processing glass containers. It can solve problems such as short service life, large deformation of the bottle body, and easy deformation of the mold, and achieve the effects of reducing temperature, avoiding deformation, and ensuring strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

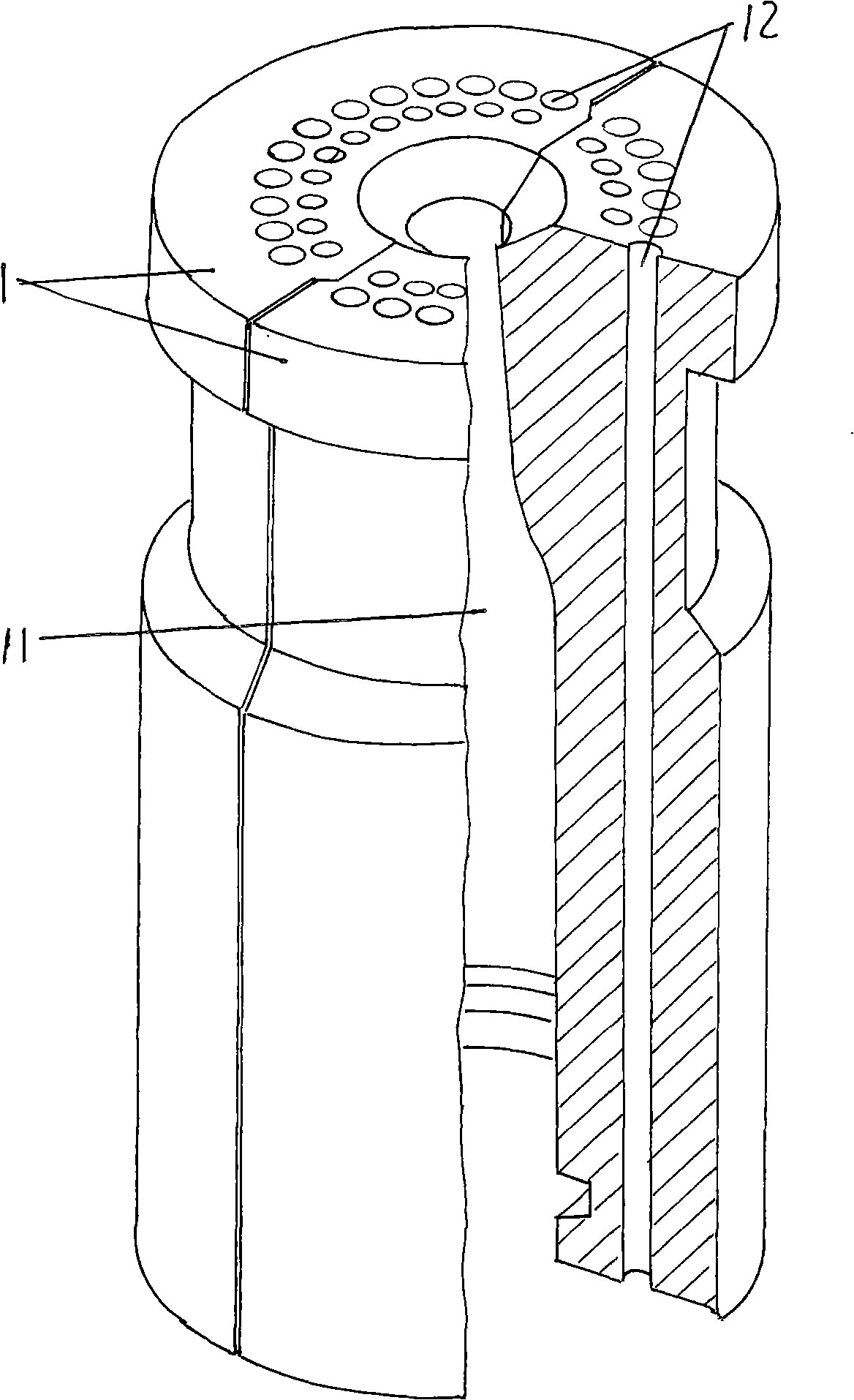

[0009] Please refer to the accompanying drawings, a pair of half-molds 1 that are closed face to face under the state of use are provided, and a mold cavity 11 with the same shape as the bottle body is processed at the center of the inner wall of each half-mold 1 . As shown in the figure, in the height direction of a pair of mold halves 1, there are ventilation holes 12 through which the upper and lower sides are spaced around the mold cavity 11. This ventilation hole 12 can also be called a vertical cooling hole. When used, it is beneficial Reduce the temperature of the bottle in the mold cavity 11 to avoid deformation of the bottle. The pitch between adjacent ventilation holes 12 is 10° based on the central angle of the mold half 1, that is, every 10° in the circumferential direction, the diameter of each ventilation hole 12 is 8mm.

Embodiment 2

[0011] The figure is omitted, only the diameter of the ventilation hole 12 is changed to 7mm, and all the others are the same as the description to embodiment 1.

Embodiment 3

[0013] The figure is omitted, only the diameter of the ventilation hole 12 is changed to 9mm, and all the other are the same as the description to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com