Low-voltage microwave radiation carbon nanotube hydroxyl modification method

A carbon nanotube and microwave radiation technology, which is applied in the field of carbon nanotube hydroxyl modification, can solve the problems of long reaction time, complicated process, high cost, etc., and achieve the effects of uniform reaction, increased hydrophilicity, and enhanced dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

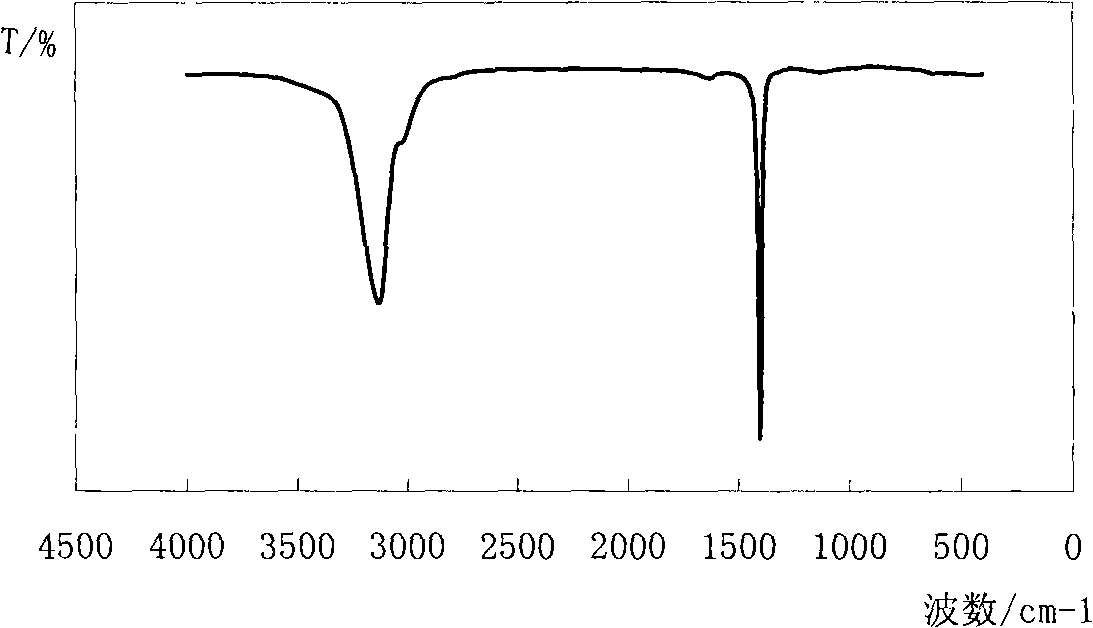

Image

Examples

specific Embodiment approach 1

[0007] Embodiment 1: In this embodiment, a method for modifying hydroxyl groups of carbon nanotubes irradiated by low-pressure microwaves is realized according to the following steps: 1. Submerge 0.5 to 2 g of carbon nanotubes in 50 mL of alkali solution, React for 1-10min under the condition of 0.2-0.5MPa, take it out and cool to room temperature, add distilled water and let it stand for precipitation; 2. Wash the precipitate with polytetrafluoroethylene film until the pH of the dripping filtrate is 6-7, and then in 80 drying at ~105°C to obtain hydroxyl-modified carbon nanotubes; wherein the concentration of the alkali solution in step 1 is 1.5-15mol / L.

[0008] In this embodiment, the carbon nanotubes are multi-walled carbon nanotubes.

specific Embodiment approach 2

[0009] Embodiment 2: This embodiment differs from Embodiment 1 in that in step 1, 0.8-1.4 g of carbon nanotubes are immersed in 50 mL of alkaline solution. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0010] Embodiment 3: This embodiment differs from Embodiment 1 in that in step 1, 1 g of carbon nanotubes is immersed in 50 mL of alkali solution. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com