Method for spraying sand on dental precious metal stove enamel renovation body bottom crown

A technology of precious metals and prosthetics, applied in dentistry, dental prosthetics, medical science, etc., can solve problems such as expensive, unmanufacturable, and poor sandblasting effects, and achieve the effect of reducing costs

Inactive Publication Date: 2008-10-29

SICHUAN UNIV

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, it cannot be produced domestically and is expensive, so it is difficult to promote

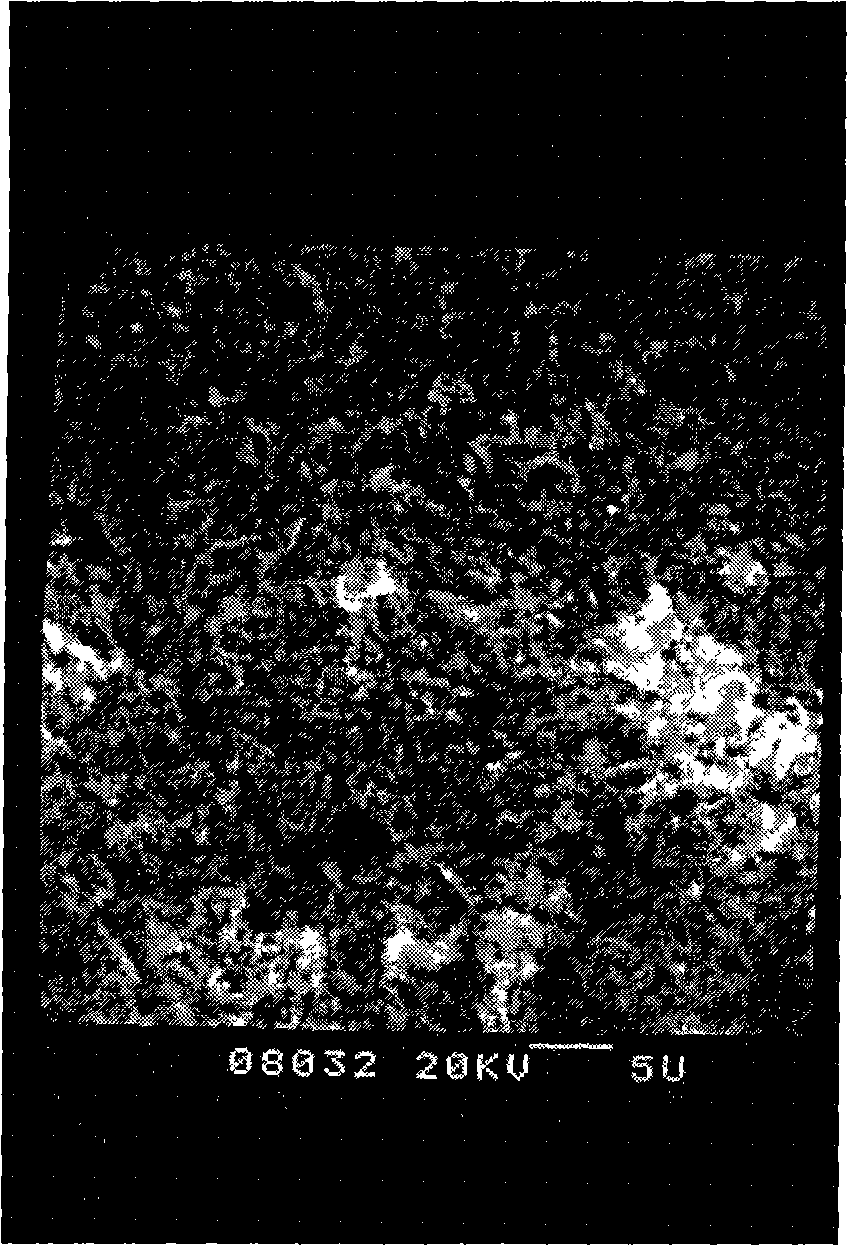

And because the particle size is the same, the difference is very small, only ±2 microns. During the sandblasting process, pits with a diameter of less than 48 microns on the surface of the precious metal inner crown cannot be treated, resulting in poor sandblasting treatment effect

However, domestically produced glass beads are not suitable for direct use in sandblasting due to their wide range of particle sizes.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Login to View More

Abstract

A sand blasting method for a dentistry restoration noble metal basic crown is that firstly, glass bead granularity is filtered, which is that the glass beads with the granularity less than 0.8mm and with uneven granularity are filtered by a 260-mesh sample sieve firstly to obtain the glass beads under the sieve, and then a 320-mesh sample sieve is used for filtering to obtain the glass beads on the sieve; secondly, the sand blasting is that the glass beads obtained by the first step is used for the sand blasting towards the dentistry restoration noble metal basic crown part by a peening machine at the pressure within the range of 0.2MP to 0.3MP, the sand blasting distance is 1cm to 1.5cm, and the sand blasting time is 10s to 16s. The method uses the glass bead with low price for the sand blasting towards the dentistry restoration, which has the advantages of low cost and good sand blasting effect.

Description

Method for sandblasting the bottom crown of dental noble metal porcelain restoration Technical field The invention relates to the preparation of a dental restoration, in particular to a method for sandblasting the bottom crown of a dental noble metal porcelain restoration. Background technique With the continuous increase of national income and the continuous maturity of clinical operations and technical skills, more and more patients choose precious metal porcelain restorations when performing dental porcelain restorations. Noble metal porcelain restorations are superior to nickel-chromium alloy porcelain restorations in terms of color effect, neck margin suitability, discoloration of neck margin, gum health, biocompatibility, corrosion resistance and castability. In the production process of the metal porcelain restoration, after the firing and glazing is completed, an incomplete oxide layer and impurities will be produced on the tissue surface of the restoration, which need ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A61C5/00

Inventor 于海洋宋斌江帆

Owner SICHUAN UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com