Bobbin fixing device and bobbin removing device

A technology of fixing device and dismantling device, which is applied in the directions of transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problems of increased man-hours for loading and unloading spools and reduced operating efficiency, and achieves the effect of easy disassembly and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

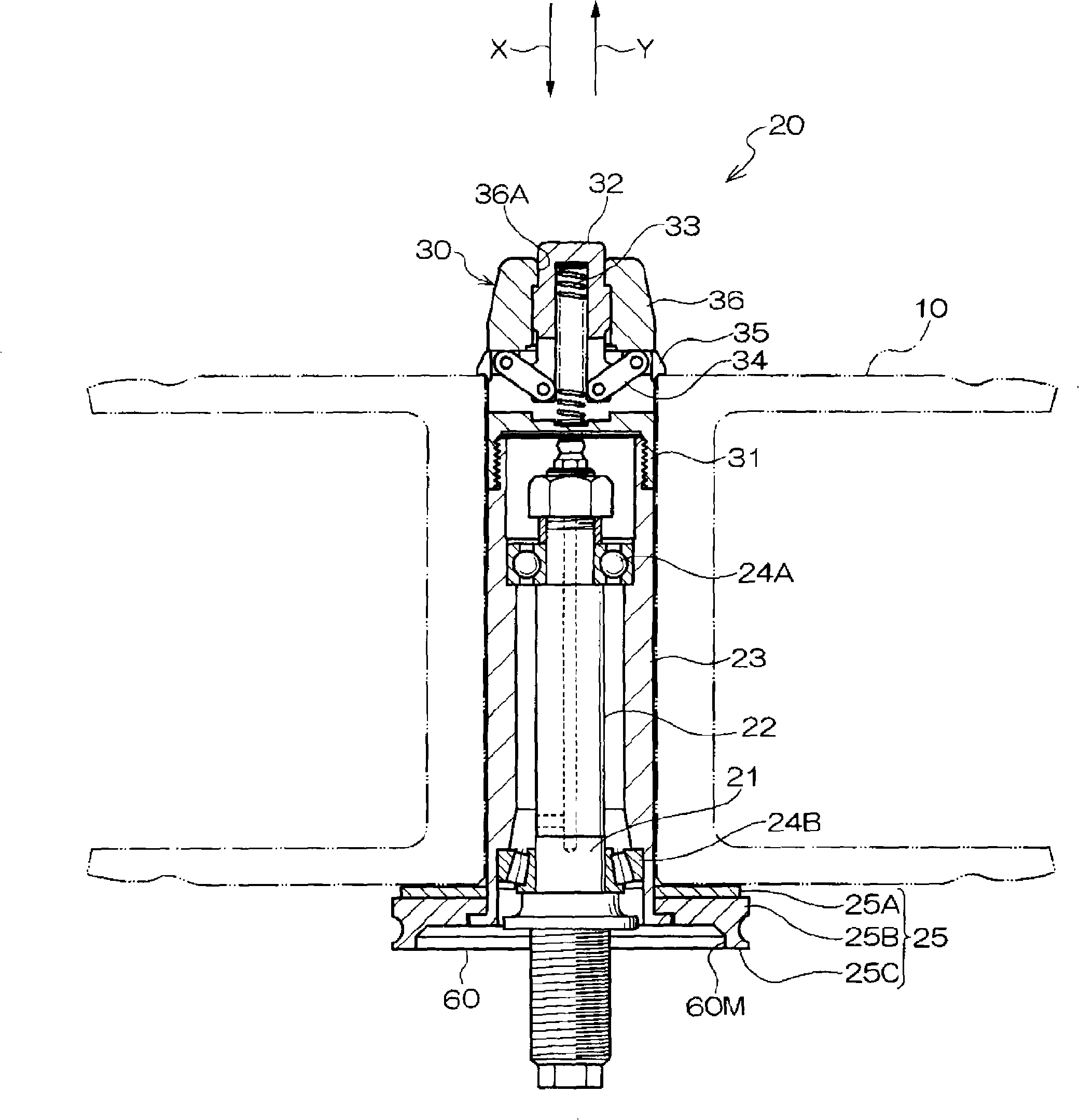

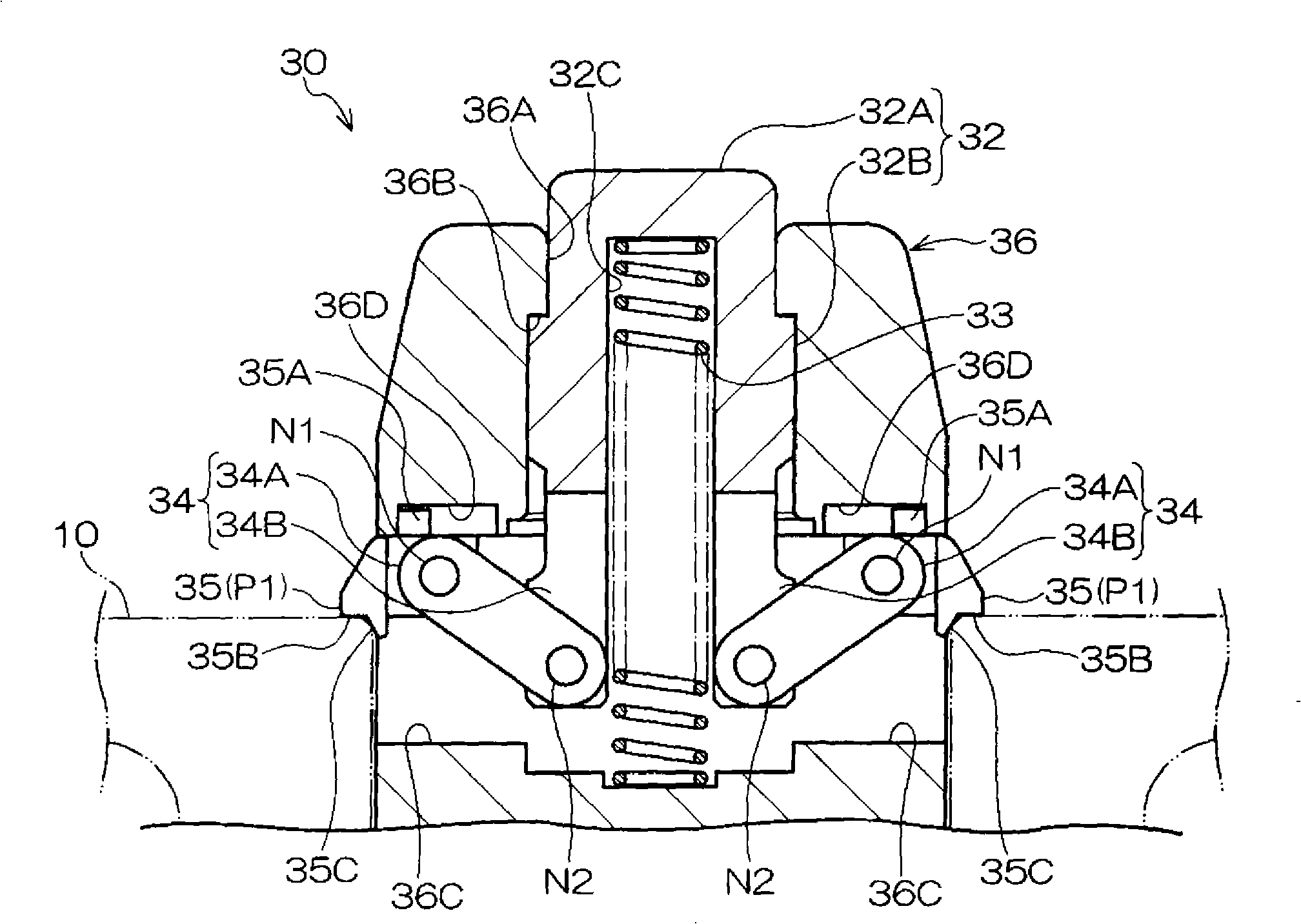

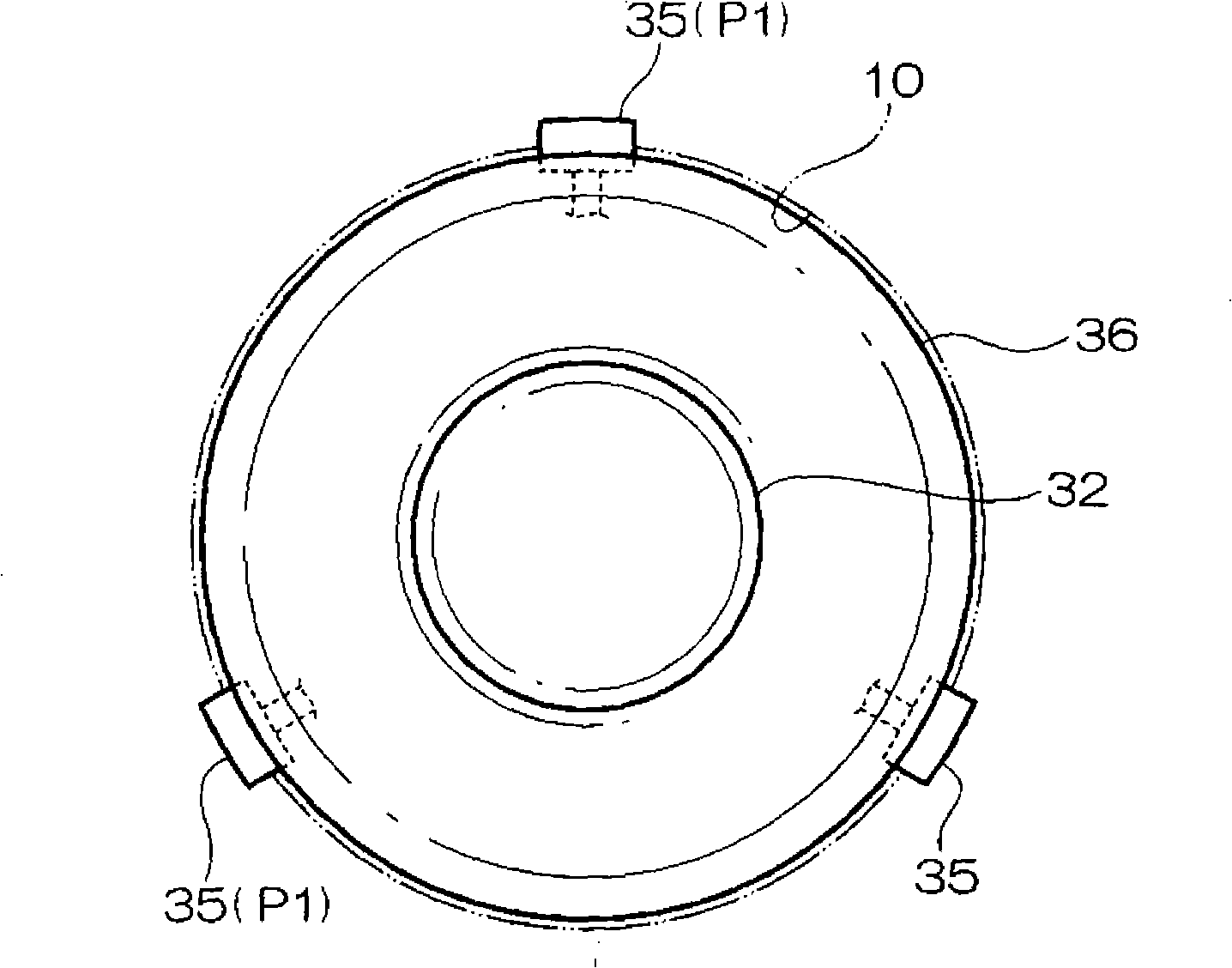

[0062] Next, a first embodiment of a bobbin removing device according to the present invention will be described with reference to the drawings. Such as Figure 6 The bobbin fixing device 20 of this embodiment shown is a device for fixing the bobbin 10 having the flange 10A and the shaft portion 10B, and has the same structure as the bobbin fixing device 20 of the present invention described above. In addition, the bobbin removal device 40 is a device for removing the bobbin 10 fixed to the bobbin fixing device 20 .

[0063] Such as Figure 6 As shown, the bobbin removal device 40 of this embodiment has a main body 42 , a holding arm 44 , and a movement allowing member 46 . The main body 42 includes a shaft portion 42A and a collar portion 42B. The shaft portion 42A is arranged on the extension line of the rotating shaft 23 of the bobbin fixing device 20 and is movable in the axial direction of the rotating shaft 23 . The shaft portion 42A has a flange portion formed on th...

no. 2 Embodiment approach

[0073] Hereinafter, a second embodiment of the bobbin removing device according to the present invention will be described with reference to the drawings. In this embodiment, the same reference numerals are attached to the same parts as those in the first embodiment, and detailed description thereof will be omitted.

[0074] The bobbin fixing device 20 of this embodiment is the same as that of the first embodiment. Such as Figure 11 As shown, the spool removal device 50 has a main body 52 , a retaining arm 54 and a movement permitting member 56 . The main body 52 includes a shaft portion 52A and a collar portion 52B. The shaft portion 52A is arranged on the extension line of the rotating shaft 23 of the bobbin fixing device 20 and is movable in the axial direction of the rotating shaft 23 . The shaft portion 52A has a flange portion formed on the lower side of the column. The collar portion 52B is disposed below the flange portion of the shaft portion 52A.

[0075] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com